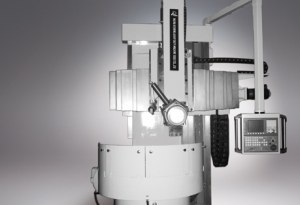

Single Column Vertical Lathe

Conventional Single Column Vertical Lathe Servo motor and gearbox directly drive the Ballscrew for X&Z axis feeding. It makes the machine better accuracy and fast-moving. The machine can equip a handheld unit for easy control. Full cover is optional together with a chip conveyor and coolant system.

Application Fields of single spindle lathe machine

Energy

Earth Moving

Die&Mold

General Machining

Engines

Features of Conventional Single Column Vertical Lathe

The single column vertical lathe is suitable for rough or fine machining of auto, bearing, wind power, motor and water pump etc.

The base and column use one-piece high quality castings.

X&Z are using brand linear guideway.

Main transmission is driven by frequency or servo motor, simple structure and high transmission efficiency.

Servo motor and gearbox directly drive the Ballscrew for X&Z axis feeding. It can reach high accuracy and fast moving.

Full cover is your optional together with chip conveyor and coolant system.

Handheld Unit.

General Description of Conventional Single Column Vertical Lathe

The conventional single column vertical lathe is a compact, high precision, heavy-duty machine. The rigid vertical column and base are quality castings, heavily ribbed for reduced thermal distortion and vibration dampening. It is designed for turning of small or medium-size workpieces.

The X and Z axis guideways are completely enclosed and a forced lubrication system assures high precision. The Ballscrew driving system enables rapid traverse rates and precision feeding traverse. The precision high-class ballscrews are driven directly by the servo motors, eliminating belts or gears for high precision.

The X & Z-axis can be working with the DRO system, the operator can easily set the tools and work an easier way to finish the machining.

The single spindle lathe can be modified to be a 2-axis CNC control if you need it in the future.

The automatic lubrication system is standard for this single spindle automatic lathe.

Parameters of Conventional Single Column Vertical Lathe

|

Model No |

CK577 |

CK518 |

CK5110 |

CK5112 |

CK5116 |

|

Max Machining Diameter(mm) |

700 |

860 |

1,000 |

1,250 |

1,600 |

|

Max Machining Height(mm) |

650 |

750 |

750 |

1,000 |

1,000 |

|

Max Load on Table(Kg) |

1,000 |

1,200 |

1,200 |

5,000 |

8,000 |

|

Table Diameter(mm) |

600 |

800 |

900 |

1,010 |

1,400 |

|

Main Motor Power(Kw) |

11 |

15 |

15 |

22 |

30 |

|

Table Rotary Speed(r/min) |

38-500 |

20-400 |

20-400 |

6.3-300 |

5-250 |

|

Horizontal Travel X(mm) |

420 |

550 |

550 |

700 |

915 |

|

Vertical Travel Z(mm) |

600 |

650 |

650 |

650 |

800 |

|

Feeding Speed of X&Z(mm/min) |

1-2,000 |

1-2,000 |

1-2,000 |

1-3,000 |

1-3,000 |

|

Position Accuracy of X&Z(mm/1000mm) |

+/-0.03 |

+/-0.03 |

+/-0.03 |

+/-0.03 |

+/-0.03 |

|

Size of Machine LxWxH (M) |

2.0x1.8x1.8 |

2.2x1.9x1.9 |

2.4x2.1x2.4 |

2.5x2.3x3.2 |

2.5x2.3x3.5 |

|

Weight of Machine (Kg) |

4,500 |

6,500 |

7,000 |

9,300 |

14,000 |

Inquiry Form

Recommended Vertical Lathe

Machine Tool Technology Applied

01

Hydrostatic Rotary Table

02

Thermo Friendly

03

DVT Mode

04

Operator Productivity

05

Cutting Performance

Contact us to buy machine tools! We have been a cnc machine tool manufacturers for many years, and our products are great.

News Room

Personne à contacter : Steven Liu, 021 57880511

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de Single Column Vertical Lathe Rechercher dans la catégorie : Divers Rechercher dans la catégorie : vertical, single, column, lathe |

Vendredi 08 mars 2013

Quantité : 10 - Prix : 80,00 €

Origine: Chine Numéro de modèle: V211141 Nom de marque: Anilutum: : Homme Matière: Style: chemise à manches longues en ligne: 9AP-5PM Anilutum Marque Slim Couleur unie manches longues Chemise V211141 Aoniludan Anilutum pour la marque hommes britannique des affaires supérieur...

H&Y International Fashion Limited

- anilutum

- EC1V 2NX - London

- +86 13724036041

Mercredi 14 septembre 2016

Quantité : 5000 - Prix : 100,00 €

Corps Acier A216 WCB & GS-C25 & 1.0619 & GP240GH - Clapet Inox 420 - Siège Inox 420 - Soufflet Inox 321 - Presse étoupe Graphite Tige et volant montants tournants - Chapeau et presse étoupe boulonnés - A brides RF PN16/ PN25/40 - Commande par volant fonte - Peinture...

ETM Armaturen

- 59590 - Henri Durre

- 86 577 67953935

Mercredi 14 septembre 2016

Quantité : 5000 - Prix : 50,00 €

Gate Valves (F4 Type) DIN Standard F4 Gate valves / (Length acc.to DIN EN 558-1,face to face series 14 ) DIN F4 Gate valve DIN absperrschieber F4 DIN Válvulas de compuerta DIN F4 šoupátko stavební délka dle DIN EN558-1 serie 14 DIN Standard F4 sluseventil (lengde iht. DIN EN 558-1...)

ETM Armaturen

- 59590 - Henri Durre

- 86 577 67953935

Paiement sécurisé