Sheet Metal Stamping

As a stainless steel fabrication factory, Shenzhen HSJ Metal Fabrication Co., Ltd. offers research and development, production of metal fabrication and various kinds of industrial parts like sheet metal stamping parts and custom sheet metal bending. HSJ sheet metal fabrication factory was established in 2015 and owns 5 years of experience in this field. HSJ adopts advanced precision metal forming & cutting technologies to provide high-quality sheet metal fabrication services.

Sheet metal stamping (also known as sheet metal pressing and forming) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape. We are one of the leading sheet metal stamping suppliers and we have custom sheet metal stamping for you.

What is Sheet Metal Pressing Process

Metal pressing and forming include a variety of sheet metal stamping manufacturing processes, such as punching by using a custom metal press machine, blanking, embossing, bending, flanging and coining, etc. This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part or could occur through a series of stages. The process is usually carried out on sheet metal.

Sheet Metal Stamping Materials

Metal stamping pressings and dies can work with various metals to diverse parts in HSJ Fabrication's steel stamping factory. Metal pressing and forming material includes SGCC galvanized plate, SECC electrolytic plate, SUS stainless steel (model 201 304 316, etc.), SPCC iron plate, white copper, red copper, AL aluminum plate (model 5052 6061, etc.), SPTE, spring steel, manganese steel. Each stamping material has its own advantages.

Benefits of HSJ Automotive Sheet Metal Stamping

- Automakers benefit from the metal stamping fabrication for different parts. The dies can be used again to manufacture parts with the same size and shape. All parts are guaranteed to meet strict specifications and tolerances.

- Key benefits of our stamping sheet metal at home include: High quality, Low Cost, long-term durability and Fast Turnaround Time.

- In HSJ Metal Fabrication, metal stamping processes can be handled almost entirely by machinery. Not only does this reduce the risk of human error or inconsistency, but it also lowers labor costs.

If you're an automotive manufacturer looking for metal stamping factory, choose HSJ Metal Fabrication.

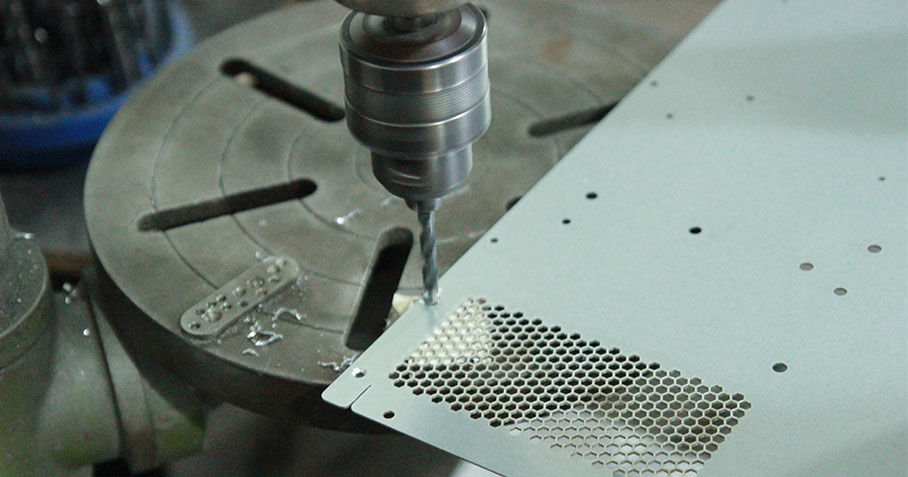

Sheet Metal Stamping Equipment

Our state-of-the-art stamping equipment produces sheet metal press parts quickly and easily, without sacrificing quality. HSJ Metal Fabrication utilizes advanced production equipment to deliver metal stamping parts of high quality, high precision.

Our advanced stamping equipment and technology includes: Quick change tooling, Die conversions, Tool and die making equipment, Press equipment

Sheet Metal Stamping Application

Auto part

We can do the custom sheet metal stamping of the chassis, fuel tank, radiator, boiler steam drum, container casing, motor, electrical iron core silicon steel sheet. Stamping parts for instruments, household appliances, bicycles, office machinery, living utensils, etc. Accuracy can reach 0.05mm, no stain on the surface, etc. For example, auto parts support.

Material: sus304

Surface: Deburring, no scratches.

Process: stamping

Accuracy: ±0.2

Electronic part

Material: Aluminum 6061-T6

Surface treatments Finish: Steel color

Process: Stamping

Tolerance: +/-0.01mm

We can also manufacture electronic parts box.

As one of the leading steel pressing companies, we offer many high quality sheet metal stamping products.

Personne à contacter : Ruan Tina, 86 755 27108658

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de Sheet Metal Stamping Rechercher dans la catégorie : Véhicule Rechercher dans la catégorie : sheet, metal, stamping |

Dimanche 10 août 2014

Quantité : as you nee - Prix : USD 3500-88888

Quick details: brand : Yong hua model; YHQ 360 Reducer: ZQ350 Ratio: 1: 31.5 roller size: 360*250 capacity: 0.1-3t/h oval size: 2.26*1.53*1.76 Spindle speed : 13-15r/min function: by pressing , the machine can mold a variety of mineral powder,metal powder, coal powder,coke...

Henan Zhengzhou Yonghua Machinery

- olina1

- 450000 - zhengzhou CITY

- +13 6 07 69 93 63

Lundi 18 juin 2007

SARL REYNAERT IMPORT/EXPORT MATERIAUX BATIMENT / OUTILLAGE / FERRAILLAGE / ENGINS DE CHANTIER UTILITAIRE Nous vendons plusieurs engins de chantier marque CATERPILLAR matériels d'occasions provenance ETAT-UNIS ou CANADA et FRANCE Prix FOB ou CIF. Toutes demandes doivent être faite...

Mercredi 14 septembre 2016

Quantité : 5000 - Prix : 50,00 €

Corps Acier A216 WCB & GS-C25 & 1.0619 & GP240GH - Clapet Inox 420 - Siège Inox 420 - Soufflet Inox 321 - Presse étoupe Graphite Tige et volant montants tournants - Chapeau et presse étoupe boulonnés - A brides RF PN16/ PN25/40 - Commande par volant fonte - Peinture...

ETM Armaturen

- 59590 - Henri Durre

- 86 577 67953935

Paiement sécurisé