PVC/WPC Pelletizing Line

PVC pelletizing extrusion line/WPC Pelletizing Line is a high-tech device used to convert materials such as Wood Plastic Composite (WPC) and Polyvinyl Chloride (PVC) into tiny pellets or granules. The extruder, cooling system, cutting and pelletizing unit, conveyor system, and control panel are all components of the pelletizing line. PVC/WPC is melted in the extruder and then cooled before being chopped into uniform-sized pellets in the cutting and wpc pelletizing machine. These pellets are then fed into the granulator for shape and finishing. The final pellets are subsequently transported to storage bins or packaging machinery through a conveying system.

QINGCHENYU provides quality custom pvc pelletizing line&WPC pelletizing extrusion lines at great prices.

Features of PVC/WPC Pelletizing Line

Specially-designed screws make plasticizing process more stable and even, as well as increase capacity greatly.

Originally-designed innovative pelletizing mould ensures immediate cooling of pellets, avoiding from sticking.

PVC&WPC Pelletizing Extrusion Lines Applications:

Pelleting PVC or WPC materials based on customers' needs.

Common PVC&WPC Pelletizing Extrusion Lines Composition:

Conical Twin Screw Extruder or Parallel Twin Screw Extruder→Pelletizing Mould→Level I Air Convey → Level II Air Convey → (Vibrating Screen) →Level III Air Convey.

Technical Specification of PVC/WPC Pelletizing Line

|

Extruder Model |

Max Capacity(kg/h) |

|

SJSZ-65/132 |

350 |

|

SJSZ-80/156 |

500 |

|

SJSZ-80/156 |

800 |

|

SJSZ-135/28 |

1300 |

*Providing quality plastic processing equipment for sale, QINGCHENYU also provides other custom pelletizing lines. Feel free to contact us at any time.

Sustainable Manufacturing Practices in PVC/WPC Pelletizing Line Operations

Sustainable manufacturing practices can be employed in PVC/WPC Pelletizing Line operations to mitigate the environmental impact of plastic processing and increase resource efficiency. These practices include using renewable energy sources to power the equipment, implementing closed-loop water systems for efficient water use and recycling of wastewater, and incorporating recycled plastic materials in the pellet production process. Additionally, proper waste management measures should be adopted to minimize material waste and minimize pollution. Overall, sustainable practices in PVC/WPC Pelletizing Line operations promote environmental stewardship, reduce energy usage and ultimately reduce production cost.

PVC/WPC Pelletizing Line Video

FAQs Of PVC/WPC Pelletizing Line

What safety features are incorporated into PVC/WPC Pelletizing Lines?

Safety features of PVC/WPC Pelletizing Lines include emergency stops, safety guards, and other protective equipment.

What types of wood-based materials can be used for WPC pellet production in a PVC/WPC Pelletizing Line?

Generally, a range of wood-based materials can be used in WPC pellet production, including sawdust, wood flour, and wood chips.

Can a PVC/WPC Pelletizing Line handle different types of materials simultaneously?

No, a PVC/WPC Pelletizing Line is designed to process only one type of material at a time.

Can PVC/WPC Pelletizing Lines recycle plastic materials?

Yes, PVC/WPC Pelletizing Lines can recycle plastic materials, including PVC and various wood-plastic composites.

There are many plastic processing machine manufacturers, but we are one of the best choices for you.

Personne à contacter : com Qingchenyu, 0512 58516595

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de PVC/WPC Pelletizing Line Rechercher dans la catégorie : Pro / B2B Rechercher dans la catégorie : pelletizing, line |

Dimanche 23 mars 2025

Quantité : 50000 - Prix : dépend du quantité

De grande qualité, agréable au toucher, légère, douce, Ultra-absorbante et sèche vite : Votre Fouta vous suivra partout, dans votre salle de bain, à la piscine, à la plage, sur le transat, le bateau ou en paréo, entourant les bébés, les enfants à la sortie du bain. Dans vos bagages...

artisanat Tunisien

- med.SGHAIER

- 5099 - Tunisia,Monastire

- +21 6 26 10 49 12

- 26104912

Mardi 16 avril 2013

Quantité : 70000 - Prix : 245,00 €

nous disposons de suffisance quantité de ferrailles voir 70000 tonnes et plus vendeur grossiste de ferraille pour plus information veuillez nous contactez PRODUIT : Ferraille TYPE : HMS1 & 2 COMPOSITION : C = 0.54 – 0.82 % Si = 0.18 – 0.40% Mn = 0.60 – 1.05% S = 0.04%Max P= 0...

sanuel

- 00228 - lome

- +22 8 96 85 74 12

Dimanche 30 novembre 2014

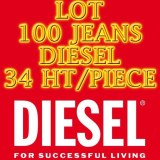

Quantité : 3000 - Prix : 34,00 €

WWW.TEXMARK.FR Grossiste, fournisseur de jeans DIESEL pour homme en lot de 100 pièces. Collection 2013-2014 - REF: Sleenker 0824p / Tepphar 0827j / Tepphar 827i / Shioner 0814p / Thanaz 0812x / Viker R Box 0088z / Safado 0827i / Tepphar 0827l / Larkee 0818n / Darron 0811v / Iakop...

SARL TEXMARK

- TEXMARK.FR

- 57500 - SAINT AVOLD

- 06 99 20 84 85

Paiement sécurisé