Progressive Die Stamping

As a professional progressive die manufacturer, ETCN provides progressive die tooling, petroleum equipment accessories, processes include stamping, CNC turning, thread processing, laser welding, laser marking, etc.

Progressive Die Stamping Capabilities

Stamping processing is the production technology of using the power of conventional or special stamping equipment to directly subject the sheet to the deformation force and deform in the mold, so as to obtain product parts with a certain shape, size, and performance. Sheet material, mold, and equipment are the three elements of stamping processing. Stamping is a metal cold deformation processing method. Therefore, it is called cold stamping or sheet metal stamping or stamping for short. It is one of the main methods of metal plastic processing (or pressure processing), and it also belongs to the material forming engineering technology.

Advantage of Progressive Die Stamping

1. The compound die stamping process has high production efficiency, convenient operation, and easy realization of mechanization and automation. This is because stamping is done by relying on punching dies and stamping equipment. The number of strokes of a popular press can reach dozens of times per minute, and the high-speed pressure can reach hundreds or even thousands of times per minute. It is possible to get a punch.

2. When stamping, because the mold guarantees the size and shape accuracy of the stamping parts and generally does not crush the general quality of the stamping parts, and the life of the mold is generally longer, the quality of the stamping is unchanged, the exchangeability is good, and it has the "identical" feature.

3. Progressive stamping press can process parts with a larger size range and more complex shapes, such as stopwatches as small as clocks, as large as automobile longitudinal beams, cage covers, etc., plus the cold deformation and softening effect of the material during stamping, and the strength and strength of the stamping the stiffness is high.

4. Stamping generally has no chips and scraps, less material loss, and no other heating equipment, so it is a material-saving and energy-saving processing method, and the cost of stamping parts is lower.

Progressive Die Stamping FAQs

Matters Needing Attention In Stamping Process Design

1. Material selection: When making stamping products, the selection of materials is very critical. According to past experience, the choice of stamping workpiece materials should take into account brand, thickness, specifications and dimensions. Only by selecting reasonable plates can it be possible to make high-quality stamping workpieces.

2. Accuracy: The accuracy of stamping workpieces is divided into the precision level and economic level. Choosing the appropriate accuracy will help control the cost.

3. Design: The design of the stamping workpiece must strictly follow the drawings approved by the prescribed procedures and meet the relevant national and industry standards.

Common Problems In The Production Of Stamping Parts

Introduction To Stamping Processing Problems

Method To Restrain Stamping Parts From Turning Over And Twisting

Punching Size Is Too Large Or Too Small

Customized Progressive Die Stamping Parts

Adapter

Copper cap

Fasten the shrapnel

Shaped Hinge

Other Machining Services You May Be Interested

Hot Forging

Hot Forging

Extrusion Molding

The products are processed by extrusion molding, with a smooth surface and high dimensional accuracy.

Extrusion Molding

CNC Milling

CNC milling, or computer numerical control milling, is a machining process which employs computerized controls and rotating multi-point cutting tools to progressively remove material from the workpiece and produce a custom-designed part or product.

CNC Milling

ETCN is a professional progressive die company and progressive die manufacturers, we provide CNC machining, metal stamping, progressive die forming, progressive die press, progressive and compound die, china cnc manufacturing, precision cnc machining china and etc. Want to know more? Please contact us.

Personne à contacter : etcn etcn, 021 61493577

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de Progressive Die Stamping Rechercher dans la catégorie : Pro / B2B Rechercher dans la catégorie : progressive, stamping |

Mercredi 03 décembre 2014

Merci, pour votre intérêt envers nos produits et notre groupe. Je suis Grace de SÄVE PAPER (Sweden), à l'avenir nous pourrons communiquer en français ou en anglais, selon ce qui vous conviendrait le mieux. Permettez-moi tout d'abord de vous pr...

SÄVE PAPER AB

- 21125 - Malmö

- +46 4 06 66 95 45

- +46 7 04 57 15 26

Mardi 26 janvier 2016

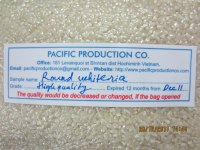

Round White Rice Type: Rice Texture: Soft Kind: White Rice Variety: Short-Grain Rice Style: Dried Cultivation Type: Common Color: White Broken Ratio (%): 5 % Max. Moisture (%): 12% Admixture (%): 5% Crop Year: new Certification: HACCP, ISO Place of Origin: Ho Chi Minh...

Pacific Production Co., Ltd

- 460000 - Ho Chi Minh

- +84 9 94 85 84 44

Dimanche 06 octobre 2013

Quantité : 1 set - Prix : USD89,000

Mobile LED Display EF22-P10(foldable) Chassis Brand OMDM External dimension(folded) 8030mm x 1600mm x 1800mm Material 16 manganese steel External dimension(unfolded) 8030mm x 3200mm x 1800mm Tire Solid rubber tires Total weight 5860kgs Brake hydraulic braker(manual&impact)...

Shanghai Jingxiang Advertisement Communication Co.,Ltd

- Lillian123

- 201900021 - Shanghai

- 008618001970686

Paiement sécurisé