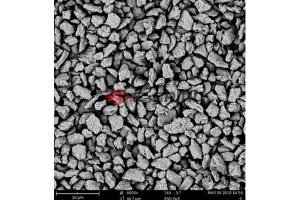

Poly (Polycrystalline Diamond Powder)

Quantité : 8000kgs Prix : USD0.025 - USD1.05

1) Properties

Detonation-synthesized polycrystalline diamond micro-powder

The structure resembles the rare natural polycrystalline black diamond, metallic-grey, superior toughness, self-sharpening.

Monocrystalline vs polycrystalline diamond:The lapping and polishing efficiency of the detonation-synthesized polycrystalline diamond micro-powder is 2 to 4 times better compared with that of the mono-crystalline diamond that is naturally occurred or synthesized via the static pressure method, Silicon Nitride, Corundum, and other abrasive materials.

polycrystalline diamond micro-powder allows the manufacturing of the smoothest surface possible:

a. When using polycrystalline diamond micro-powder of size 2-4micron to the polishing surface, Ra(roughness)<1.6nm</span>

b. When using polycrystalline diamond micro-powder of size 0-0.5micron to the polishing surface, Ra(roughness)<1.3-1.4nm</span>

c. When using polycrystalline diamond micro-powder of size 0-0.125micron to the polishing surface, Ra(roughness)<0.1nm</span>

polycrystalline diamond can maintain its dull mono-crystalline structure by releasing the outer layer, hence will produce the most scratch free surface possible.

When applied to the surface of a workpiece (for example, the inner surface of a cylinder in an engine) via chemical plating method, the wearability of the surface is superior to that of a surface treated with any other materials.

Via after-sinter technique, polycrystalline diamond micro-powder can be turned into polycrystalline diamond particles of a large size that are highly valuable in a variety of industries.

2) Application

Lapping and polishing a variety of surfaces that require superior smoothness.

Improving the wearability of a mechanical component

Via after-sinter technique can be applied in a variety of industries.

Can be made into liquid abrasives, gel abrasives, and many other types of abrasive tools that are capable of ultra-fine lapping and polishing tasks.

Industries:

Polycrystalline diamond micron powder can be used for below industries:

Computer industry: Read/Write head lapping, rigid disk media texturing

Gem polishing

Semi-Conductor, electronic ceramic, optical instruments

Used as anti-wearing media in special rubber and plastics

Chemistry catalyst, Biomedicine

With more than 20 years experience, E-Grind provides all sizes of Poly (Polycrystalline diamond micron powder) with high removal rate, superior surface finishing, and long using life. Our Quality Control Department keeps strict and careful control of raw material from lot to lot to ensure quality basis. All the products are tested during production and after processing, to make sure of quality consistency and quality traceability. The test report is attached to each shipment for customers reference.

Available Sizes:

0-0.15, 0-0.2, 0-0.35, 0-0.5, 0.25-0.35, 0-1, 0-2, 2-4, 3-6, 3-7, 4-8, 4-9, 6-10, 6-12

Custom-made sizes are also available upon customers' demand.

- Grind Abrasives is one of the most professional polycrystalline diamond suppliers of diamond and CBN products with over 50 years experience. If you want to know more about the abrasive powder types, just contact us! We sincerely invite and welcome people from all around the world to invest and create more values together.

Personne à contacter : Liu Locke, 0371 68616868

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de Poly (Polycrystalline Diamond Powder) Rechercher dans la catégorie : Biens d'équipement Rechercher dans la catégorie : diamond, powder, polycrystalline, poly |

Friday 16 May 2014

Quantité : 5000000 - Prix : $0.50-5/pc

Profil D'entreprise: Entièrement équipé d'avancées machines cnc, nous avons de riches expériences de fabrication de précision pièces usinées, pièces tournées, fraisage pièces selon les dessins pour vous livrer le haut- cran produits. nos installations de fabrication sont prêts à...

Xiamen Karo Co.,Ltd

- karoplastic

- 361002 - Xiamen

- 0086 592 5135406

Wednesday 05 August 2015

Nous vendons sauf vente entre temps la machine suivante : * Heidelberg SM74-5-H, Année 2004 52x74 - 5 Couleurs - env. 140 mio impressions Modèle SE, Vitesse 13.000 fph Equipée avec : . CP 2000 PrintCenter (avec MasterLevel and PresetLink) . Autoplate (Calage de Plaques Semi-Automatique) ...

ACS DIFFUSION s.a.s.

- acsdiffusionsa

- 42952 - Saint-Etienne

- 0033 (0)4 77 92 77 88

- 06 10 63 37 83

Wednesday 17 February 2016

Quantité : 2000MT - Prix : $3500/MT CIF

2016 (New Crop New Harvest) Color: Brown Odor: Characteristic Quality: Handpicked clean Size: Homogenous CG3 Volatile oil: 20%-25% Foreign matter: 0% Moisture: 13% - 15% Baby Cloves: 2% Max. Origin: Madagascar Packing: 50 Kg Bag New Jute Bags Minimum Quantity: 1 X 20 FCL...

KHUN JACK PARTNERSHIP LIMITED

- 50000 - CHIANG MAI

- +66 9 56 19 49 81

Paiement sécurisé