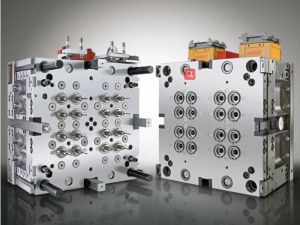

PC Injection Molding

Prix : 1 000,00 €

PC is classified as a ''thermoplastic'', and the name has to do with the way the plastic responds to heat. Thermoplastic materials become liquid at their melting point (155 degrees Celsius in the case of Polycarbonat). A major useful attribute about thermoplastics is that they can be heated to their melting point, cooled, and reheated again without significant degradation. Instead of burning, thermoplastics is like Polycarbonate liquefy, which allows them to be easily injection molded and then subsequently recycled.

PC is commonly used for plastic lenses in eyewear, in medical devices, automotive components, protective gear, greenhouses, Digital Disks (CDs, DVDs, and Blu-ray), and exterior lighting fixtures.

Injection molding most often produces parts by polycarbonates and their blends. Since polycarbonate is highly viscous, it is usually processed at high temperature to reduce its viscosity. In this process, the hot polymer melt is pressed through into a mold with high pressure. The mold when cools, gives the molten polymer its desired shape and characteristics. This process is generally used to manufacture polycarbonate bottles, plates etc. Since polycarbonate is a poor-flowing plastic, wall thickness should not be too thin.

Properties of PC Injection Molding

Mechanical performance: high strength, fatigue resistance, dimensional stability, and small creep (also rarely changes under high temperature conditions);

Heat aging resistance: The enhanced UL temperature index reaches 120 ~ 140 ℃ (long-term outdoor aging is also very good);

Solvent resistance: no stress cracking;

Stability to water: easy to decompose under water at high temperature (use caution in high temperature and high humidity environment);

Insulation performance: excellent (moisture and high temperature can also maintain stable electrical performance, is an ideal material for manufacturing electronic and electrical parts);

Dielectric coefficient: 3.0-3.2;

Arc resistance: 120s;

Form ability: injection molding or extrusion of ordinary equipment.

We provide custom plastic injection molding china ,polycarbonate injection,pc abs injection molding,molding polycarbonate ,polycarbonate injection molding and injection molded parts,you can consult us injection molding cost and can polycarbonate be injection molded,contact us now.

Personne à contacter : Lu Cally , 86 0769 82926607

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de PC Injection Molding Rechercher dans la catégorie : Divers Rechercher dans la catégorie : molding, injection |

Mercredi 04 juin 2025

Découvrez tous nos articles high-tech et accessoires pour smartphones au sein de notre showroom situé à Aubervilliers ou directement sur notre boutique en ligne http://www.vipgros.com. Nous proposons un large choix d'articles pour les proffessionnels de la téléphonie et du multimédia...

Vendredi 13 juin 2008

Quantité : As per dem - Prix : Negotiable

We have vast arrangement and well experienced team of workers for Leather Garmrnts-Fashion, Motor Bike Jacket,Pants, Skirts etc. High quality leather garments as per requirements of Clients. If some one wants us to develop his design,do send us design and we will feel pleasure to...

Sayor Int'l.

- sayor

- 51310 - Sialkot

- +92 5 23 61 05 15

- 0092 321 7101608

Vendredi 01 juin 2007

Quantité : 1 000 000 - Prix : US$127/ton

We wish to import copper and cobalt concentrates from the D R Congo into Zambia. Please contact us quickly for earliest business. This will be a contract arrangement for a period of 5 years and will be paid on a monthly basis in leu of collection. Please note that we require high...

Chemtec Enterprises Ltd

- chemtec

- 280051 - Kitwe

- +2602225669

- +26 0 95 46 00 93

Paiement sécurisé