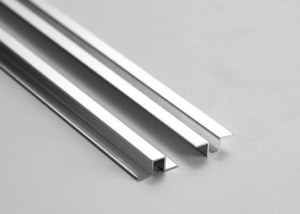

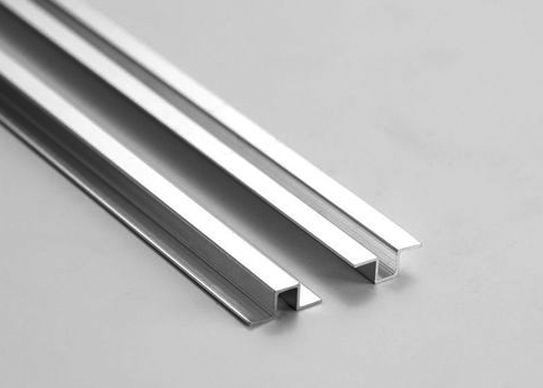

METAL FLANGING

Flanging refers to the stamping process of turning the edge or outer edge of the hole on the workpiece into an upright straight edge with a die. It is included in the forming process of stamping.

WHAT IS THE ADVANTAGE OF METAL FLANGING?

It can process precision stamping parts with complex shape and good rigidity.

Improve the production efficiency. Save dies for some deep drawing parts. Reduce the manufacturing cost.

It can replace the deep drawing work of a complex shape workpiece, so flanging is especially suitable for small batch trial production.

Flanging is usually applied at the edge of the stamping part, which can effectively save the material.

WHAT SHOULD BE CONCERNED IN METAL FLAGGING?

1. The flanging degree of inner hole of stamping parts shall not be too large at one time.

Flanging is a stamping method that turns the workpiece with holes punched in advance into vertical flange along the hole edge. The deformation of hole flanging is from the tensile deformation of the material along the tangential direction, and the closer to the edges, the greater the deformation and the flanged area of workpiece gets thinner. Due to that, the hole edge may be cracked if not dealt properly. In order to prevent the cracking, the flanging degree of the inner hole of the workpiece must not be too large. If the flanging height is large, we can process flanging several times instead.

2. The flanging coefficient of punching flanging shall not be too small.

In flanging, the deformation degree is expressed by cofficient "K", which is the ratio of the aperture before flanging to the aperture after flanging. Obviously, the larger the value of K, the smaller the degree of deformation. On contrary, the smaller the value of K, the greater the degree of deformation, and more likely the edge of the flanging hole will be broken. The minimum value of K occurs with the maximum deformation degree which can be achieved without cracking the hole edge.

In order to prevent edge cracking, K shall not be too small and shall be greater than the minimum value introduced above. Experience shows that the minimum value of K is not only related to the type and performance of the material, but also to the relative thickness of the blank, and the shape of the product.

As a metalworking factory, we can offer sorts of metal work fabrication for sale, if you are interested, please leave us a message.

Personne à contacter : com hunkmachining, 0553 2861635

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de METAL FLANGING Rechercher dans la catégorie : Destockage Rechercher dans la catégorie : metal, flanging |

Lundi 25 mars 2013

Quantité : 12 - Prix : 62,00 €

Importateur vends lots de sanzas ou carimbas : diamètre 12 cm touches métalliques face bois exotique fond demi noix de coco . Très bonne sonorité. Vendus par lot de 25 pièces : 62,50 € le lot, soit 2,50 € la pièce. Minimum d'achat un lot. Si cette proposition vous plait, il suffit...

OUTRE MERS

- outremers

- 17110 - SAINT GEORGES DE DIDONNE

- +33 6 81 16 68 53

Mardi 11 novembre 2014

Quantité : 3000000KGS - Prix : USD0.89 PER KG

ER70s-6 welding wire,gas shilded welding wires Shandong Zander Sourcing Company Limited - place of orginal: Shandong,China. - Brand name: Zander - Material: CO2 - Diameter: 0.8mm - Standard: AWSER70S-6 - Specifications : er70s-6 welding wire ;fast depositing speed;high...

Shandong Zander Resourcing Co.Ltd

- zanderwelding

- 250200 - zhangqiu

- 86 531 83231687

- 86 15552539082

Vendredi 16 mai 2014

Quantité : 500000pcs - Prix : $1-25/pc

SLA et SLS Pourquoi utiliser stéréo lithographie? Stéréo lithographie est très similaire à la sls( frittage laser sélectif) processus de prototypage. Il est préférable d'utiliser sla, quand finition de surface et l'apparence générale directement de la machine est le facteur le...

Xiamen Karo Co.,Ltd

- karoplastic

- 361002 - Xiamen

- 0086 592 5135406

Paiement sécurisé