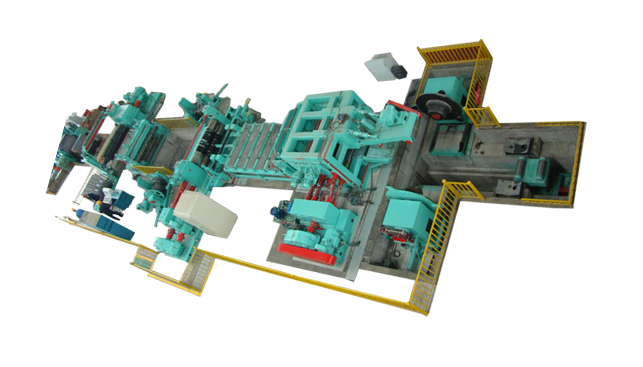

Medium Gauge Slitting Lines

RISHBIN Medium Gauge Slitters is used to slit the big rolls into narrow rolls, and packaging it automatically. It works of max. thickness up to 10mm, max. width of up to 2200mm, and speed of up to 100 m/min. It consists of Decoiler with coil car, guiding & pinch device, medium gauge slitters, dual head/quick tooling change for the auto slitting machine is available, scrap winder, side-guiding device, looping, tension device, recoiler. Different materials could be suitable to be processed in the line, such as pre painted steel coil, cold rolled steel coil, hot rolled carbon steel coil, stainless steel coil, copper, brass, aluminum and titanium. These narrow coils/rolls are widely used in Steel Pipe Factory, Steel Structure Factory, Storage System Manufacturing Factory, combined with Roll Forming Machine, Power Punch Machine, Pipe Mills.

To help you achieve your own production capacity target, RISHBIN automatic slitting machine supplies many options, such as high speed slitting, medium speed slitting, etc. All slitters are easy to operate. They are very reliable, steady performers for both short and long terms running productions.

- The thickness can range from the thinnest down to 1.0 mm, to the thickest up to 10mm

- Strip Width, from the narrowest 400 mm to the widest 2200 mm

- Coils Weight, up to 35 tons

- Line Speed, up to 100 m/min.

- Operator Safety.

- Highest Production Outcome

- Ease of Operation and Maintenance

Working procedure:

In the beginning, the coil is loaded on the coil car by crane and brought to the uncoiler by operating the coil car. Coil car centralizes the coil with the uncoiler mandrel and the coil is mounted on the uncoiler. Mandrel is expanded. Snubber roll rotates the coil. Peeler breaks the straps and brings the pre end upto Pinch roll. The Pinch roll drives the coil end upto the slitter. Then its drive is disconnected. Slitter moves the slitted strips further. Slitted strips are threaded through loop table and drag tensioner into the recoiler drum. Recoiler winds one turn on loose coil.

Then drag tensioner and loop are put into operation. Slitter and recoiler run simultaneously in synchronization. As the coil build up, the recoiler rpm correspondingly goes down to keep desired constant line speed. This process goes on until the end of coil on uncoiler. The slitted coil is pushed on the exit coil car through a pusher plate operated by hydraulic cylinder. The side slitted scrap is wound on the scrap winder units provided on both sides of the slitter.

|

Model No. |

RS 1.0-6.0 |

RS 2.0-8.0 |

RS 3.0-10.0 |

|

|

Coil Material |

CR Coils , HR Coils, S.S Steel Coils, GI Coils , AL Coils, Copper Coils Picking Oil Coils |

|||

|

Coil Thickness |

1.0~6.0mm |

2.0~8.0mm |

3.0~10.0mm |

|

|

Line Speed |

0~110m/min |

0~50/80m/min |

0-30/50m/min |

|

|

Coil Weight |

≤30T(35T) |

≤30T(35T) |

≤30T(35T) |

|

|

Coil I.D |

Φ508,φ610,φ760mm |

Φ508,φ610,φ760mm |

φ508,φ610,φ760mm |

|

|

Coil O.D |

≤φ2200mm |

≤φ2200mm |

≤φ2200mm |

|

|

Strip Width |

≥30mm |

≥50mm |

≥70mm |

|

|

Number of Strip |

4~15 |

5~20 |

5~18 |

|

|

Slitting Accuracy |

±0.3mm |

±0.3mm |

±0.3mm |

|

|

Blade shaft |

Ф260mm |

Ф280mm |

Ф300mm |

|

|

Electrical Control System |

PLC Automatic control |

PLC Automatic control |

PLC Automatic control |

|

Customized slitting lines for every different kind of metal strip and in all required dimensions would be available.

Main Technical Specifications

|

COIL/ROLL DETAILS |

Material |

HR, CR, SS, GI, PPGI, Copper |

|

Tensile Strength |

δb≤600Mpa,δS≤360Mpa |

|

|

Coil/Roll thickness |

1-10mm |

|

|

Steel Coil/Roll width |

500-2200(Max) |

|

|

Coil/Roll I.D |

Φ500-760 mm |

|

|

Coil/Roll O.D |

Φ2000mm(Max) |

|

|

Steel Coil/Roll Weight |

35T(Max) |

|

|

Slitter parameters |

knife pivot diameter |

Ф220 mm |

|

Knife pivot material |

40Cr |

|

|

Blades specification |

Φ220mmXφ360mmX20mm |

|

|

Blade material |

6CrW2Si |

|

|

Max slit quantity |

4 pcs (4mm) 20 pcs(1mm) |

|

|

Width precision |

≤±0.05mm |

|

|

Other parameters |

Power |

380V/50Hz/3Ph(Customized) |

|

Line speed |

0-80m/min |

|

|

Capacity |

360 KW |

|

|

Whole line Dimension |

45m(L)X10m(W) |

|

|

Line direction |

From right to left(Face to machine) |

|

|

Machine color |

Blue |

Contact

RISHIBN CO., LTD, one of the most professional slitting lines machinery manufacturers from China, which integrated R&D, production, sales and technical service altogether, we provide clients proper slitting machines based on different cutting materials. Welcome your visit.

Company name: RISHBIN CO, LTD.

Company Address: No. 10, Jingshi Rd, Wuxi, China

Phone Number: +86-510-85853379

Mobile/WhatsApp/Wechat: +86-18626315075

Fax Number: +86-510-85853378

E-mail: info@steelslitter.com

Customer Service: service@rishbin.com

Personne à contacter : Ho Chris, 0510 85853379

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de Medium Gauge Slitting Lines Rechercher dans la catégorie : Divers Rechercher dans la catégorie : gauge, lines, slitting, medium |

Thursday 03 October 2019

Prix : 56 €/m²

Bâtiment métalliques modulaires toutes dimensions, temporaires ou définitifs. Bâtiments en kit extensibles et entièrement démontable. Structure métallique principale composés de profils de type " C" ou " SIGMA " formés à froid et galvanisés, structure secondaire sur couverture et...

HADDOUCHE

- 33140 - CADAUJAC

- 06 72 47 36 41

- +33 6 72 47 36 41

Thursday 13 March 2014

Quantité : 960 - Prix : 6.00 euro

RL-COL7 7 Pcs Color Coated Knife Set + Peeler Prepare your food confidently with ergonomic anti-slip handles Non-Stick coating provides clear-cut and easy cleaning action Stainless Steel blades preserves its sharpness for a long time - 8″ Carving Knife - 8″ Chef Knife -...

n/a

- SLM1603 - Sliema

- +35 6 21 33 09 18

- +35 6 79 40 54 43

Friday 18 July 2025

Quantité : Customers - Prix : Negotiable

Aerona Beauté réalisons une large sélection de Amincissement ciseaux fabriqués à partir de haute qualité en acier inoxydable AISI-440C et AISI-420. Chaque paire de Amincissement ciseaux coupe avec cohérence et avec une action confortablement lisse. Ces ciseaux sont miroir poli, Sable...

Aerona Beauty manufacturers of beauty care instruments

- aeronabeauty

- 51310 - Sialkot

- 923217106500