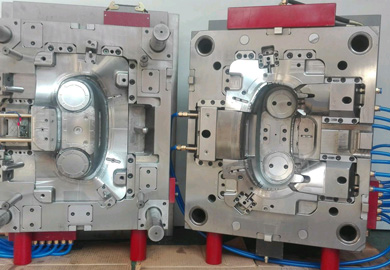

Medical Equipment Mould

Medical Equipment Mould

Medical device injection molding is a process using medical-grade plastic materials to manufacture different durable medical parts and components. The medical device plastic injection molding process can provide benefits for a variety of applications such as medical enclosures, needles, surgical instruments, prosthetics, and so on.

GM-TECH is one of injection molding manufacturers. Our medical device molding parts and components with relatively low plastic injection molding cost are safe and reliable, which deserves your trust.

Features of Medical Equipment Mould

Due to the high-quality materials, the medical device injection molding process can be performed smoothly and safely, which ensures the medical parts are durable and reliable. These medical-grade plastics have become the ideal material for different kinds of electronic medical equipment. Several features that our medical device plastic injection molding service can provide, include:

Reduced weight

Increased functionality

Lower cost

The decreased burden of sterilization

The Specification of Medical Equipment Mould

|

Part material |

ABS |

|

Cavity |

1 + 1 |

|

Mould accuracy |

+ / - 0.02mm |

|

Mould steel |

H13 |

|

Mouldbase steel |

1.173 |

|

Mould life |

100W |

|

Mould standard |

DME |

|

Mould structure |

1 slides |

|

Exporting country |

USA |

|

Leadtime |

5 weeks |

|

Mould quality customer satisfaction |

0.98 |

|

FAI pass rate |

0.96 |

|

Project cooperation service customer satisfaction |

0.98 |

How does Medical Equipment Mould Work?

When it comes to the working principle of medical device molding, it is inevitable to mention the medical process machine. The medical device precision injection molding machine consists of three parts, namely the feed hopper, the screw, and the heated barrel.

When the feed hopper receives the plastic granules, it uses the frictional action of the screw to create heat. Once the plastic reaches the correct temperature, it is then injected into the medical device plastic injection mold cavity. Finally, it gradually keeps cooling and takes the shape of the designed medical device molding part.

If you want to buy high quality plastic moulded products, please contact us.

Personne à contacter : Kevin Shaw, 0086 0769 8535 7333

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de Medical Equipment Mould Rechercher dans la catégorie : Pro / B2B Rechercher dans la catégorie : medical, equipment, mould |

Samedi 01 août 2015

ACAFA Full control PC under any OS, in BIOS mode, during boot, at Blue Screens Model: AI101P Single Port KVM over IP Description: The KVM over IP technology (IP-KVM) combines digital remote KVM access via IP networks with comprehensive and integrated system management. The IP-KVM...

ACAFA Information co,Ltd

- wendy2015

- 335000 - Taoyuan

- +88 6 33 07 13 00

Lundi 07 septembre 2015

- Feature (click here for details) - - Under the LAN can support more than 10 simultaneous client connections cameras, image lag within 100 milliseconds, supports standard streaming media network protocols, network 8 M per channel bit rate case, no mosaic - The DSP processor...

ZT Technology Group Ltd.

- ellazhan

- 852 - Fo Tan

- +85 2 26 75 75 58

Samedi 06 avril 2013

DESTOCKAGE.COM Contact : - Email : Leveque11@wanadoo.fr - Tel : 0033 763127272 ACHAT-VENTE EN GROSSE QUANTITE TEXTILE (pas de fripes) - CHAUSSURES Destockages en provenance de l’Europe-Vietnam-Bengladesh OUTILLAGE provenance Europe DIVERS ENGINS -...

sarl destockage.com

- leveque11

- - LE MANS

- 07 63 12 72 72

Paiement sécurisé