Magnetic Flux Leakage Testing Equipment

Quantité : 5000 units Prix : 8-2 million

Electromagnetic detection is a very important non-destructive testing method and is widely used. Mag flux testing is a magnetic method of nondestructive testing that is used to detect corrosion and pitting in steel structures, most commonly pipelines and storage tanks.

The basic magnetic flux leakage principle is that a powerful magnet is used to magnetize the steel. When used in combination with other methods, it provides a quick and inexpensive assessment of the workpiece of ferromagnetic materials. With the advancement of technology, people are paying more and more attention to the automation of the inspection process. This not only reduces the labor intensity of the inspection work but also improves the reliability of the test results and reduces the influence of human factors.

The MFI magnetic flux leakage testing method is a highly automated magnetic flux testing technology. The magnetic flux leakage principle is that after the ferromagnetic material is magnetized, the surface and near-surface defects form a leakage magnetic field on the surface of the material, and defects are detected by detecting the leakage magnetic field. In this sense, the magnetic particle detection technology commonly used in pressure vessel inspection. However, it is customary to use the method of measuring the leakage flux with a sensor as the magnetic flux leakage ndt detection, and the magnetic flux to detect the leakage flux. The method is called magnetic particle detection and they are juxtaposed into two detection methods.

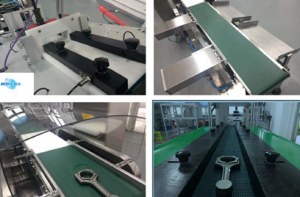

Portable Magnetic Flux Leakage Testing Equipment

Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of a test piece after it is magnetized due to defects on the surface or near surface of the test piece.

Benchtop Magnetic Flux Leakage Testing Equipment

Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of a test piece after it is magnetized due to defects on the surface or near surface of the test piece.

Magnetic particle testing can only detect surface and near-surface crack defects, and it needs surface grinding when testing. It is only suitable for the detection of workpiece discontinuation. In addition to the surface and near-surface crack defects, the MFI magnetic flux leakage inspection can also find the corrosion inside the workpiece from the outside. Defects such as pits, and do not need to be polished on the surface of the workpiece, suitable for on-line inspection of workpieces. On-line inspection of workpieces is currently the most urgent method for users, which can reduce unnecessary parking and reduce inspection costs. In addition, the magnetic flux leakage detection can also quantify the depth and length of defects. Although the application of magnetic flux leakage detection technology is rarely used in workpiece inspection, it has the advantages that magnetic particle detection does not have, so its application prospect is very broad.

As a non destructive testing equipment manufacturer and supplier, we have been committed to developing and manufacturing high-quality and high-performance NDT equipment to provide customers with the best quality service.

As one of the most professional mfl suppliers, BKN provides ndt testing machine, ndt testing, ndt ultrasonic testing equipment, ndt device, etc. Want to know magnetic flux leakage testing procedure or what is magnetic flux leakage? Please contact us.

Personne à contacter : Li Hui, +86 025 52244360

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de Magnetic Flux Leakage Testing Equipment Rechercher dans la catégorie : Pro / B2B Rechercher dans la catégorie : leakage, equipment, flux, magnetic, testing |

Saturday 26 July 2014

Quantité : 15 SETS - Prix : As the model nimber

1,Introduction of the China manufacturing metal powder and charcoal/coal briquettes making machine /machine pellet By pressing,the machine can mold a variety of mineral powder,metal powder,coal powder,coke powder and other materials. Due to the use of forced squeeze by pair roller ...

China

- 450000 - xushui

- 086 0371 67813791

Thursday 21 March 2013

Quantité : 100 - Prix : $1590

SD Connect with Lenovo X61T Touch Screen Laptop--$1590 FREE SHIPPING. If you want to get more PRODUCT information,please do not hestitate to contact me.yeah,It will be your wise choice. Welcome to visit our website!Top quality! Fast delivery! Competitive price! Version:C304 Mercedes-Benz...

MaxiDAS708 Automotive Co., Ltd

- orconniezz

- 518109 - shenzhen

- 8675529071623

Tuesday 22 September 2015

1. Brief introduction of the Inflatable sports Inflatable Sports is one of the most important products in our company. The automated high-speed cutting machines are used to prepare the materials accurately.We also use high-end welding and laminating machines to ensure the quality...

Zhengzhou Wolong Amusement Equipment Co., Ltd.

- Emma Xu

- 450000 - Zhengzhou

- 86 13673711652

Paiement sécurisé