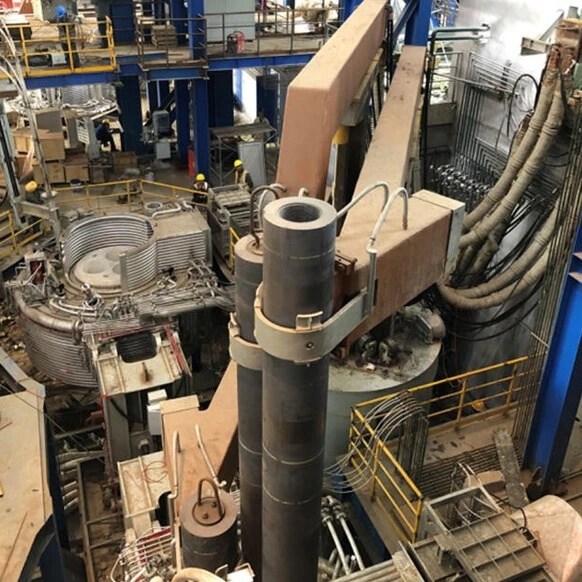

LRF LADLE REFINING FURNACE

Quantité : 20 sets/ye Prix : 100,000-50 million

LRF ladle refining furnace is the most widely used refining equipment outside the furnace at present. The LRF furnace is used to refine the molten steel melted in the primary furnace, and can adjust the molten steel temperature and buffer the process.

The ladle furnace refining equipment has many advantages, such as reasonable equipment structure, reliable operation, low cost, many refined steel types, high quality and convenient operation.

FUNCTIONS

CONDITIONS AND FUNCTIONS OF LRF IN STEEL MAKING

The LF furnace specification is from 8t to 300t, and has the following conditions and functions:

The working conditions in the LRF steel making furnace are reducing atmosphere and micro positive pressure;

The electrode adjustment mode of the industrial furnace ladle is three arm three-phase electrode adjustment;

The thermodynamic condition of the ladle heating furnace is graphite electrode arc heating;

The dynamic condition is argon stirring at the bottom of the ladle;

Add a certain amount of scrap crushing material into the ladle, heat it up with electric arc, measure the temperature and take samples to make the temperature control accurate, so as to optimize the pouring temperature;

Bottom blowing argon stirring to make the temperature of molten steel uniform, the composition uniform and the molten steel pure;

Slagging to remove sulfur and inclusions in molten steel;

Adjust the alloy composition and use the alloy feeding system to make the composition control accurate and the molten steel meet the final required chemical composition;

Wire feeding treatment: directly feed various wires into molten steel with a wire feeder, which can significantly improve the yield of alloy;

Smoke exhaust and dust removal. Equipped with a smoke exhaust and dust removal system, it can effectively control the smoke discharge and make the smoke emission meet the requirements of environmental protection;

As the ladle refining equipment outside the ladle arc furnace between the primary refining furnace and the continuous caster, it plays a buffer and regulating role in the production process of the whole workshop to ensure that molten steel with qualified temperature and composition is provided to the continuous caster.

STRENGH

LRF LADLE REFINING FURNACE FEATURES

LRF Ladle Refining Furnace Features

The features of the LRF furnace are as follow:

Electrode rotation dual station;

Ladle turret dual station technology;

Online wire feeding technology;

Automatic temperature measurement and sampling technology;

The technology of adding scrap steel to refining furnace;

Argon blowing automatic control technology;

LF one touch steelmaking technology.

We provide lrf steel making, lrf in steel making, ladle refining furnace process, ladle arc furnace, ladle furnace steelmaking, etc. For more information about types of furnace used in steel plant, please feel free to contact us!

Personne à contacter : Kzao Justin, 86 029 89613639

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de LRF LADLE REFINING FURNACE Rechercher dans la catégorie : Biens d'équipement Rechercher dans la catégorie : refining, ladle, furnace |

Mardi 11 août 2015

One Lus International is a professional security padlock manufacturer in Taiwan and provides a series of security padlock to meet customer's needs. The heavy duty padlock is anti-thief hardened shackle, tube and side covers are with high security, the shackle can be taken out. If...

One Lus International Co., Ltd.

- onelusinter

- 833 - Kaohsiung City

- +88 6 77 32 85 66

Jeudi 13 mars 2014

Quantité : 960 - Prix : 6.00 euro

RL-COL7 7 Pcs Color Coated Knife Set + Peeler Prepare your food confidently with ergonomic anti-slip handles Non-Stick coating provides clear-cut and easy cleaning action Stainless Steel blades preserves its sharpness for a long time - 8″ Carving Knife - 8″ Chef Knife -...

n/a

- SLM1603 - Sliema

- +35 6 21 33 09 18

- +35 6 79 40 54 43

Mercredi 16 mai 2007

CMR SA Contact : M. Mehmet Cecen Adresse : 7 grande rue Luxembourg, l 1661 Luxembourg Disque DIAMOND SPEED pour le profesionnel. Disque diamant soudé-laser avec liant titane ultra robuste. Alliant la haute performance et la polyvalence. Conforme aux normes de qualité EN 13236....

Paiement sécurisé