Les systèmes de flottation à air dissous (DAF) éliminent les matières en suspension, le...

Product Description

Dissolved Air Flotation (DAF) systems remove suspended solids, fats, oils, greases and non-soluble organics

Dissolved Air Flotation (DAF) Systems

Dissolved Air Flotation is a proven and effective physical/chemical technology for treating a variety of wastewater streams

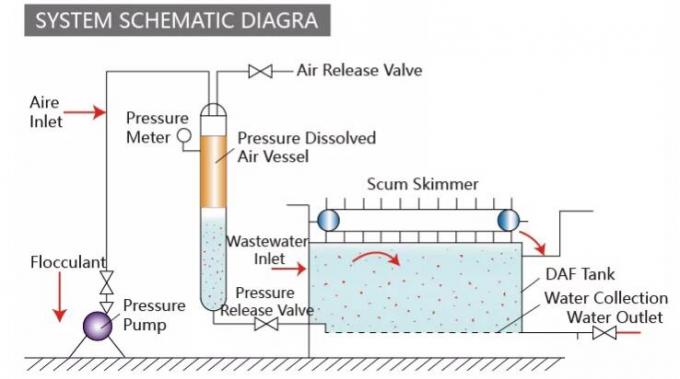

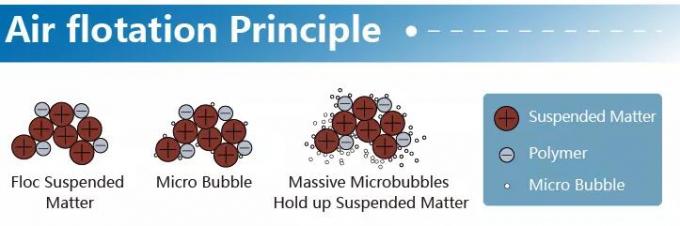

DAF systems are designed to remove total suspended solids (TSS), biochemical oxygen demand (BOD), and oils and greases (O&G) from a wastewater stream. Contaminants are removed using a dissolved air-in-water solution produced by injecting air under pressure into a recycle stream of clarified DAF effluent. This recycle stream is then combined and mixed with incoming wastewater in an internal contact chamber where the dissolved air comes out of the solution in the form of micron-sized bubbles that attach to the contaminants. The bubbles and contaminants rise to the surface and form a floating bed of material that is removed by a surface skimmer into an internal hopper for further handling.

Dissolved air flotation (DAF) is a proven and effective physical/chemical technology for treating a variety of industrial and municipal process and wastewater streams. DAF systems are commonly used for the removal of oils & greases and suspended solids to meet a variety of treatment goals including:

- Product recovery and reuse

- Pretreatment to meet sewer discharge limits

- Pretreatment to reduce loading on downstream biological treatment systems

- Polishing of biological treatment effluent

- Thickening of biosolids

One of the most common DAF applications is for the pretreatment of wastewater to remove suspended solids and oils and greases prior to discharge to a municipal sewer or a biological treatment system. For example:

A Pretreatment DAF can be used by an industrial discharger to meet specific limits for oil and grease and/or suspended solids set by a municipality (e.g., to meet a discharge limit of 100 mg/L O&G, etc.).

An industry may need to use a Pretreatment DAF to remove contaminants (e.g., product solids, oils and greases, heavy metals, etc.) that would negatively impact a biological wastewater treatment system downstream.

In most cases, the wastewater contaminants must be chemically flocculated in order for the floatation system to remove them. Pretreatment DAF is used in about every industry class. DAF has proven to be very effective for the removal of biological solids from wastewater streams. Some of the advantages over traditional, gravity clarification include:

- Smaller footprint and more rapid implementation

- Higher sludge solids content (4%TS vs. 1%TS) resulting in a much lower sludge volume

- Ability to handle bulking solids that tend to float

- More reliable effluent quality

| Model | Capacity | Power(kw) | Dimension(m) | Nozzle list(DN) | |||||||

| (m3/h) | Recirculation pump | Air compressor | Skimmer | Sludge scraper | L/L1 | W/W1 | H/H1 | Inlet | Outlet | Sludge outlet | |

| SDAF-003 | ~3 | 0.75 | 0.55 | 0.18 | 3.4/2.2 | 2.4/1.7 | 2.4/1.9 | 80 | 80 | 100 | |

| SDAF-005 | ~5 | 1.1 | 0.55 | 0.18 | 3.8/2.5 | 2.2/1.5 | 2.5/2.1 | 80 | 80 | 100 | |

| SDAF-010 | ~10 | 1.5 | 0.55 | 0.18 | 5.1/3.8 | 2.4/1.7 | 3.0/2.4 | 100 | 100 | 100 | |

| SDAF-015 | ~15 | 2.2 | 0.75 | 0.18 | 5.1/3.8 | 2.9/2.2 | 3.0/2.4 | 100 | 100 | 100 | |

| SDAF-020 | ~20 | 3.0/5.5 | 0.75 | 0.18 | 5.4/4.1 | 2.9/2.2 | 3.0/2.4 | 150 | 150 | 150 | |

| SDAF-030 | ~30 | 3.0/5.5 | 0.75 | 0.18 | 5.5/4.2 | 3.2/2.5 | 3.2/2.6 | 150 | 150 | 150 | |

| SDAF-040 | ~40 | 4.0/5.5 | 0.75 | 0.18 | 6.5/5.2 | 3.2/2.5 | 3.2/2.6 | 200 | 200 | 150 | |

| SDAF-050 | ~50 | 7.5 | 0.75 | 0.18 | 1.5 | 7.2/5.9 | 3.2/2.5 | 3.2/2.6 | 200 | 200 | 150 |

| SDAF-060 | ~60 | 7.5 | 1.5 | 0.18 | 1.5 | 7.6/6.7 | 2.7/3.3 | 3.3/2.7 | 250 | 250 | 150 |

| SDAF-070 | ~70 | 11 | 1.5 | 0.18 | 1.5 | 8.1/6.7 | 3.6/2.9 | 3.3/2.7 | 250 | 250 | 150 |

| SDAF-080 | ~80 | 11 | 2.2 | 0.18 | 1.5*2 | 9.4/8.5 | 3.1/2.4 | 3.3/2.7 | 250 | 250 | 150 |

| SDAF-100 | ~100 | 15 | 2.2 | 0.18 | 1.5*2 | 10.0/8.8 | 3.7/3.0 | 3.3/2.7 | 300 | 250 | 150 |

| SDAF-120 | ~120 | 15 | 2.2 | 0.18 | 1.5*2 | 10.9/9.7 | 3.7/3.0 | 3.3/2.7 | 300 | 300 | 150 |

| SDAF-150 | ~150 | 18.5 | 2.2 | 0.18 | 1.5*2 | 13.5/12.2 | 3.7/3.0 | 3.3/2.7 | 350 | 300 | 150 |

| SDAF-200 | ~200 | 22 | 2.2 | 0.18*2 | 1.5*4 | 10.8/9.6 | 6.7/3.0 | 3.3 | 300*2 | 250*2 | 150 |

| SDAF-300 | ~300 | 30 | 5.5 | 0.18*2 | 1.5*4 | 13.5/12.6 | 6.7/3.0 | 3.3/2.7 | 350*2 | 300*2 | 150 |

Application

As a waste water process, DAF clarifier is widely used in sewage treatment and water purification engineering. DAF clarifier is suitable for:

l Increase effluent recycling and fresh water reusing in paper and pulp

l Removal of heavy metal ions

l Separation of oil refinery effluent

l Removal of tannery wastewater

l Removal of chromaticity and impurities in printing and dyeing wastewater

l Solid-liquid separation of sewage and membrane after all kinds of bio-treatment

l Sludge concentration (capacity: 20%~ 30%, except the dedicated device which can be designed according to the requirements)

Process description

Pollutants in sewage can be divided into dissolved organic matter and insoluble matter (SS). Dissolved organic matter can be converted into insoluble matter. One of the methods of sewage treatment is to add coagulants and flocculants to transfer most of the dissolved organic matter to insoluble matter, and then clean up most of the insoluble matter. (SS) to achieve the purpose of purifying sewage, and the main method of cleaning SS is the use of air flotation.

After adding chemicals, the sewage enters the mixing zone of air flotation, and mixes with the released dissolved air water, so that the floc adheres to the fine bubbles, and then enters the air flotation zone. Flocculants float to the water surface under the action of air buoyancy to form scum. After the clear water from the lower layer flows to the clear water tank through the water collector, some part will reflux as the dissolved air water, and the remaining clean water flows out through the overflow outlet. When the scum accumulates on the surface of the air flotation tank, it will be scraped and discharged into the sludge tank.

During the air floatation process, a large number of fine and uniformbubbles (5 ~ 8 microns) are formed to form a three-phase mixture of airbubbles, water,and flocs (oil). They contact and adhere together to takeshape of air-containing flocs that float to the surface and are mechanicallyscrap by scum skimmer. Then water will be purified.

The theoretical basis of the air-dissolving process is Henry's Law meansthat in air-floatation system, air dissolves in water under high pressure andapproaches saturation, and is released under reduced pressure to normalpressure.

Personne à contacter : Mr. Joe Zu, +86 15052233707

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de Les systèmes de flottation à air dissous (DAF) éliminent les matières en suspension, le... Rechercher dans la catégorie : Biens d'équipement Rechercher dans la catégorie : dissous, eliminent, suspension, systemes, matieres, flottation |

Tuesday 09 December 2025

Nous sommes les principaux fournisseurs de boissons énergisantes comme Red Bull, requin, chargeur et bien d'autres.Nous pouvons également fournisseur can boissons comme Pepsi, Coca cola, Fanta, Sprite et autres produits.Nous fournissons également la meilleure qualité de l'eau minérale...

Vente en Gros

- 40400 - Kuala Lumpur

- +60 1 46 26 71 59

- +60 1 42 85 90 62

Tuesday 03 June 2014

Quantité : 200000

Avantages de l'aluminium d'emballage Emballages en aluminium offre un haut niveau de résistance à la corrosion. Il fournit des propriétés de protection optimale en offrant une barrière imperméable métallique aux rayons lumineux, ultra-violets, la vapeur d'eau, les huiles et les graisses...

moroccopack

- khalail

- 20000 - casablanca

- 212661046374

Sunday 06 October 2013

Quantité : 1 set - Prix : USD125,000

Product parameters: Parameters EW4700-S12-P10 (Complete Vehicle) Chassis Brand Foton Aumak External 8310mm x 2175mm x 3750mm Power Cummins Curb weight 3700KGS Emission standards Euro IV Total Weight 14495KGS Seat One and half row A 1995 Wheelbase 4700mm Hydraulic Lifting...

Shanghai Jingxiang Advertisement Communication Co.,Ltd

- Lillian123

- 201900021 - Shanghai

- 008618001970686

Paiement sécurisé