Hot Runner Mould for Pump Base

Prix : 1000-6000USD

Hot Runner Mould for Pump Base

Hot Runner Molds for Water Pump Bases

The hot runner injection molding process is an advanced concept of thermal engineering which refers to moulds using a heated device to make them melt in the runner never solidify. We provide you with different types of hot runner moulds of high quality.

Advantages of hot runner injection molding for pump base

There are some advantages of hot runner injection molding under below:

1. Save raw materials and reduce shell mould casting costs.

2. Shorten the molding cycle and improve the machine efficiency

3. Improve the surface quality and mechanical properties of products.

4. Pin-point gate can be used without the three-plate mould in china.

5. It can be economically molded into a single product by using side gate.

6. Improve automation of shell molding casting process.

7. Can use needle valve gate to control gate freezing.

8. Consistent quality of injection parts using multi-cavity molds.

9. Improve the surface beauty of injection shell mold and molding.

10. Small injection pressure can be used to effectively reduce the post-deformation of thin-wall products, so as to meet the shell moulding process requirements.

Matters of choosing hot runner mold supplier

Hot runner mold suppliers often make their hot runner components into product series according to the size and weight of the processed plastic parts. During the hot runner injection molding process, large plastic parts are processed with large size nozzle, while small plastic parts with small size nozzle. So after users choose the right hot runner type (hot tip or valve type system), they will then choose hot runner mold product series to decide the structural size and design of molds. If the hot runner mold product series is not chosen correctly and is found in the late mold processing or in the production of plastic parts, the error caused is very serious and difficult to save. To assist in the correct selection of hot runner mold product series, each hot runner mould supplier has a number of guidance technical documents for reference,in ppt forms, pdf forms or other forms available. Users should cooperate closely with the hot runner mold supplier to choose the right type of hot runner mould series.

If you want to know more about shell moulding process requires, please visit our website.

We have types of hot runner mould for sale, if you have needs, please contact us.

Personne à contacter : Yokini Wang, 021 67696068

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de Hot Runner Mould for Pump Base Rechercher dans la catégorie : Divers Rechercher dans la catégorie : pump, runner, base, mould |

Saturday 02 April 2016

We are the first patented waterproof LED Corn light in China. LED Replacement Lamps for Metal Halide / High Pressure Sodium/High Intensity Discharge/CFL Material Private mode 6063 Aluminum thermal structure; High quality aluminum processing technique; Special su rface treatment process...

Shenzhen snuoer technology Co., LTD

- 518103 - shenzhen

- +86 755 18682173476

Sunday 11 May 2014

Prix : 250,00 €

OFFRE DE SERVICE Bonjour; Nous somme une nouvelle société créée pour répondre aux besoins de nettoyage de tous types de locaux : Administratif, Hôtelier, Particuliers. Nous disposons du matériel et du produit avec des performances très hautes. Nous proposons nos services à des...

Entreprise de nettoyage

- 16000 - Cheraga

- 05 50 99 10 81

- 213550991081

Sunday 31 May 2015

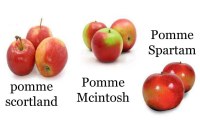

Quantité : container - Prix : fob

Nous representons une entreprise basé en europe, pour vous une offre de pomme de qualité superieure au sénégal et en Afrique (voir les trois varièté de pommes) MCINTOSH: Croquant Juteux Moyennement acide Moyennement sucré Aromatique CORTLAND : Croquant Moyennement acide...

Trading Partner

- algore

- X - Dakar

- 221 33 824 38 53 / 221 77 779 42

- 70 720 53 66

Paiement sécurisé