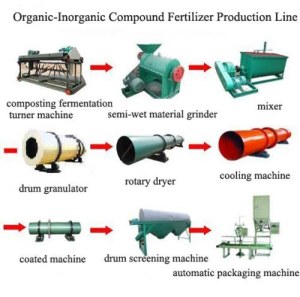

High-quality Organic Granulated Fertilizer Production Machine

Production of high-quality organic granular fertilizer is a complex task as the process is subject to various factors: variety and quality of raw materials, composition and compatibility of material formulation, moisture content and its variation during the granulation process, quality and degree of abrasion of the operating parts of the fertilizer grinder and the organic fertilizer granulator used, correct selection and setting of equipment operating modes, etc. This means that producers of organic granulated fertilizers need to take into account all the elements and stages of the technological process of granulation. In a competitive market, this cannot be overlooked or ignored. In the granulation process, there are several factors affecting the quality of the final (new) product. Some authors claim the quality of granulated product is mostly affected by the composition of granules (20 %), pressing quality 15 %, material shredding parameters up to 20 %, additional processing approximately 40 %, as well as the drying cooling process.

It is indisputable that part of soil fertility improvement is organic fertilizer. The main source of organic fertilizer remains livestock waste – cattle and poultry manure. Whereas scarcely used, when the price of mineral fertilizer increased and ecological problems appeared, a decrease of soil fertility and humus has been noticed. When applying conventional manure removal, preparation and application methods in addition to not using stricter environmental requirements can have a negative impact on the key components of the environment. This can be prevented by properly wasting, composting and granulating agricultural waste. The resultant product is humus compost, which presents no problems and no the difficulty of keeping it and has no unpleasant odor, pathogenic organisms or other fitotoxical materials, it also accelerates the metabolism of nutrients between the soil and plant roots of plants.

Organic granular fertilizer improves the dynamics of microbiological processes in granules and around them which allows reducing the spread of nutrients in the soil and their transition to less agile forms, besides that it results in better circumstances for processes taking place between the fertilizer, soil and plant. Granular manure is a universal complex organic fertilizer containing all the macro and micro elements. Pelleted manure nutrient content for soil micro flora is optimal; moreover, it quickly dissolves in water and is easily absorbed by plants. Granular manure can be called concentrated fertilizer, because the recycling process reduces the volume of material more than 10 times, due to water removal and material thickening while extruding. Granulation – the set of natural and physical-mechanical processes, which take place during the formation of little pieces, which has a dimension of the ranges, forms, structures and physical properties. Granulation allows significant simplification of the storage, transport and dosage; moreover, it increases powdery while together eliminating dusting and improving the working conditions in the production sphere, besides that, it can regulate the granule structure and related properties. The granulation process efficiency depends on the method of granulation and technology.

The consequence of all physical-mechanical processes that are taking place while pelleting is that granulated material density increases. In the organic fertilizer pellet making process we can see all known physical-mechanical and physical-chemical bonds, accompanied by such forces as the capillary force and forces between the solid particles, temperature changes affecting the forces and so on. The granulation process itself depends on the feedstock grain size and physical-mechanical properties. (Temperature, moisture content, pH, etc.). The main parameter describing the performance of pelletizer and the energy cost required by material compaction is the granule formation speed. As the speed of granulation increases the granular material density and mechanical strength decrease.

Personne à contacter : Forbes Elena, 8637165950309

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de High-quality Organic Granulated Fertilizer Production Machine Rechercher dans la catégorie : Environnement / Ecologie Rechercher dans la catégorie : fertilizer, granulated, production, quality, high, machine, organic |

Wednesday 10 September 2014

Implantée à Madagascar, depuis 2006, la société ANJAVIDY, fabrique et exporte des clôtures en brande de bruyère, des produits de qualité, entièrement façonnés à la main et totalement occultant 7 à 8cm d'épaisseur. ANJAVIDY exporte aussi de la sphaigne sous différents conditionnements...

Anjavidy

- 501 - Tamatave

- 09 50 58 47 69

Tuesday 15 March 2016

Quantité : 1 pallet - Prix : £728.73

iForce Auctions are an auction site that deal with the onward selling of branded clearance stock from major retailers. Since its launch in 2008 we have become a pioneer of the onward selling of 'unwanted' goods and developing B2B relationships with small businesses and individual customers...

iForceAuctions

- B8 1JW - Birmingham

- +44 7860430987

Tuesday 11 November 2014

copper wire for saleER70S-6,co2 mig welding wires Shandong Zander Sourcing Company Limited 1.place of orginal: Shandong,China. 2.Brand name: Zander 3.Material: CO2 4.Diameter: 1.0mm 5.Standard: AWSER70S-6 6.Specifications : er70s-6 welding wire ;fast depositing speed;high...

Shandong Zander Resourcing Co.Ltd

- zanderwelding

- 250200 - zhangqiu

- 86 531 83231687

- 86 15552539082

Paiement sécurisé