Heavy Gauge Slitting Lines

Quantité : 20 Prix : 20,000 USD - 800,000

Machine Reviews

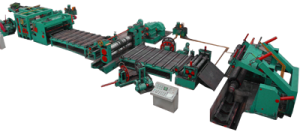

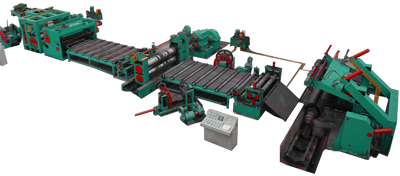

RISHBIN Heavy Gauge Slitters are designed to slit high strength heavy gauge materials. Coils max. thickness of up to 20mm, max. width of up to 2500mm, and speed of up to 60 m/min. It consists of Decoiler with coil car, guiding & pinch device, heavy gauge slitters, dual head/quick tooling change for slitter is available, scrap winder, side-guiding device, looping, tension device, recoiler. Different materials could be suitable to be processed in the line, such as pre painted steel coil, cold rolled steel coil, hot rolled carbon steel coil, stainless steel coil, copper, brass, aluminum and titanium. Here you cna buy high quality slitting machines.

To help you achieve your own production capacity target, RISHBIN Slitter supplies many options, such as high speed slitting, medium speed slitting, etc. All slitters are easy to operate. They are very reliable, steady performers for both short and long terms running productions.

The thickness can range from the thinnest down to 3.0 mm, to the thickest up to 20 mm

Strip Width, from the narrowest 400 mm to the widest 2500 mm

Coils Weight, up to 35 tons

Line Speed, up to 60 m/min.

Minimum Burr on strip.

Automatic Coil Loading

2 complete slitting heads for quick offline tooling changeovers.

Straight edged recoiling.

Economic efficency due to high automation level.

Ease of Operation and Maintenance

Slitting Lines are available in different sizes and models as per the demands and specifications laid by the clients.

It is available in different capacities and standards according to the demand of the clients.

These heavy gauge slitting lines are widely appreciated amongst our clients for their user friendly designs and high resistance to temperature variations.

Working procedure:

In the beginning, the coil is loaded on the coil car by crane and brought to the uncoiler by operating the coil car. Coil car centralizes the coil with the uncoiler mandrel and the coil is mounted on the uncoiler. Mandrel is expanded. Snubber roll rotates the coil. Peeler breaks the straps and brings the pre end upto Pinch roll. The Pinch roll drives the coil end upto the slitter. Then its drive is disconnected. Slitter moves the slitted strips further. Slitted strips are threaded through loop table and drag tensioner into the recoiler drum. Recoiler winds one turn on loose coil.

Then drag tensioner and loop are put into operation. Slitter and recoiler run simultaneously in synchronization. As the coil build up, the recoiler rpm correspondingly goes down to keep desired constant line speed. This process goes on until the end of coil on uncoiler. The slitted coil is pushed on the exit coil car through a pusher plate operated by hydraulic cylinder. The side slitted scrap is wound on the scrap winder units provided on both sides of the slitter.

|

Model No. |

RS 3.0-12.0 |

RS 4.0-16.0 |

RS 6.0-20.0 |

|

|

Coil Material |

CR Coils , HR Coils, S.S Steel Coils, GI Coils, AL Coils, Copper Coils Picking Oil Coils |

|||

|

Coil Thickness |

3.0~12.0mm |

4.0~16.0mm |

6.0~20.0mm |

|

|

Line Speed |

0 ~ 60m / min |

0 ~ 50m / min |

0-50m / min |

|

|

Coil Weight |

≤30T (35T) |

≤30T (35T) |

≤30T (35T) |

|

|

Coil I.D |

φ508, φ610, φ760mm |

φ508, φ610, φ760mm |

φ508, φ610, φ760mm |

|

|

OD coil |

≤φ2200mm |

≤φ2500mm |

≤φ2500mm |

|

|

Strip Width |

≥100mm |

≥100mm |

≥100mm |

|

|

Number of Strip |

5~20 |

≤5 |

≤5 |

|

|

Slitting Accuracy |

±1.0mm |

±1.0mm |

±1.0mm |

|

|

Blade shaft |

F320 |

Ф340mm |

Ф360mm |

|

|

Electrical Control System |

PLC Automatic control |

PLC Automatic control |

PLC Automatic control |

|

Heavy Gauge Slitting Line Specifications

|

COIL/ROLL DETAILS |

Material |

HR, CR, SS, GI, PPGI, |

|

Tensile Strength |

δb≤550Mpa, δS≤260Mpa |

|

|

Coil/Roll thickness |

6-20mm |

|

|

Steel Coil/Roll width |

600-2500(Max) |

|

|

Coil/Roll I.D |

Φ500-760 mm |

|

|

Coil/Roll O.D |

Φ2500mm(Max) |

|

|

Steel Coil/Roll Weight |

35T(Max) |

|

|

Slitter parameters |

knife pivot diameter |

Ф360 mm |

|

Knife pivot material |

40Cr |

|

|

Blades specification |

Φ360mmXφ360mmX20mm |

|

|

Blade material |

6CrW2Si |

|

|

Max slit quantity |

4 pcs (16mm) 8 pcs(8mm)(Customized) |

|

|

Width precision |

± ± 0.05mm / 2m |

|

|

Other parameters |

Power |

380V/50Hz/3Ph(Customized) |

|

Line speed |

0-60m / min |

|

|

Capacity |

450 KW |

|

|

Whole line Dimension |

45m(L)X10m(W) |

|

|

|

|

|

|

Line direction |

From right to left(Face to machine) |

|

|

Machine color |

Blue |

Do you want to buy buy slitting line? Rishbin was founded in 1999. With almost twenty years development, now it becomes a leading professional supplier in the field of Metal Coil Processing Machinery industry, and exports its quality production line to the markets all over the world.We sincerely invite and welcome people from all around the world to invest and create more values together.

Personne à contacter : Chris Ho, 0510 85853379

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de Heavy Gauge Slitting Lines Rechercher dans la catégorie : Biens d'équipement Rechercher dans la catégorie : lines, heavy, gauge, slitting |

Samedi 05 juillet 2025

Mandatée par plusieurs fermes de héliciculture en Albanie, je voudrais vous faire part de la production de chez, escargot BIO muni par un certificat de qualité ISO. L'un des fermes dont je suis mandataire a meme reçu cette année le prix l'escargot d'or. Pour toute personne intéressée...

JOANCONSULT

- 1000 - Tirana

- 00355682129449

Jeudi 16 mai 2013

Quantité : 1000 - Prix : 2,75 €

Poliester 80%, Nylon 16%, Elasthane 4% Grammage : 290g/m2 Origine : Chine Largeur : 150 cm Longueur : 80-100 m Prix : 2.92 Eur (livraison incluse en France) Minimum de 1 rouleau par référence lors de la commande Localisation : Neustr. 110-118, 42553 Velbert, Personne à contacter ...

Fuba Gmbh

- 42553 - Velbert

- +33 6 24 18 11 70

Mardi 30 juin 2015

Quantité : 1kg - Prix : 5 Euro

FIRST TRADING TUNISIA ;Nous sommes une société tunisienne spécialisée dans l'importation et l'exportation et la vente de toutes les matières, nous vous proposons de tomates séchées,1kg à 5 Euro ,une carton contient10kg ( FOB) Si vous êtes intéressé, s'il vous plaît nous contacter...

FIRST TRADING TUNISIA

- 2001 - Ariana

- +21 6 71 81 12 85

- +21 6 97 57 19 54

Paiement sécurisé