Heavy Gauge Slitting Lines

Heavy Gauge Slitting Lines

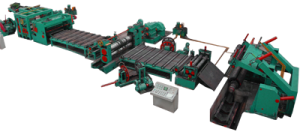

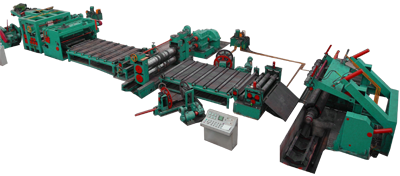

RISHBIN Heavy Gauge Slitters are designed to slit high strength heavy gauge materials. Coils max. thickness of up to 20mm, max. width of up to 2500mm, and speed of up to 60 m/min. It consists of Decoiler with coil car, guiding & pinch device, heavy gauge slitters, dual head/quick tooling change for slitter is available, scrap winder, side-guiding device, looping, tension device, recoiler. Different materials could be suitable to be processed in the line, such as pre painted steel coil, cold rolled steel coil, hot rolled carbon steel coil, stainless steel coil, copper, brass, aluminum and titanium. Here you cna buy high quality slitting machines.

To help you achieve your own production capacity target, RISHBIN Slitter supplies many options, such as high speed slitting, medium speed slitting, etc. All slitters are easy to operate. They are very reliable, steady performers for both short and long terms running productions.

The thickness can range from the thinnest down to 3.0 mm, to the thickest up to 20 mm

Strip Width, from the narrowest 400 mm to the widest 2500 mm

Coils Weight, up to 35 tons

Line Speed, up to 60 m/min.

- Minimum Burr on strip.

- Automatic Coil Loading

- 2 complete slitting heads for quick offline tooling changeovers.

- Straight edged recoiling.

- Economic efficency due to high automation level.

- Ease of Operation and Maintenance

- Slitting Lines are available in different sizes and models as per the demands and specifications laid by the clients.

- It is available in different capacities and standards according to the demand of the clients.

- These Slitting Lines are widely appreciated amongst our clients for their user friendly designs and high resistance to temperature variations.

Working procedure:

In the beginning, the coil is loaded on the coil car by crane and brought to the uncoiler by operating the coil car. Coil car centralizes the coil with the uncoiler mandrel and the coil is mounted on the uncoiler. Mandrel is expanded. Snubber roll rotates the coil. Peeler breaks the straps and brings the pre end upto Pinch roll. The Pinch roll drives the coil end upto the slitter. Then its drive is disconnected. Slitter moves the slitted strips further. Slitted strips are threaded through loop table and drag tensioner into the recoiler drum. Recoiler winds one turn on loose coil.

Then drag tensioner and loop are put into operation. Slitter and recoiler run simultaneously in synchronization. As the coil build up, the recoiler rpm correspondingly goes down to keep desired constant line speed. This process goes on until the end of coil on uncoiler. The slitted coil is pushed on the exit coil car through a pusher plate operated by hydraulic cylinder. The side slitted scrap is wound on the scrap winder units provided on both sides of the slitter.

|

Model No. |

RS 3.0-12.0 |

RS 4.0-16.0 |

RS 6.0-20.0 |

|

|

Coil Material |

CR Coils , HR Coils, S.S Steel Coils, GI Coils, AL Coils, Copper Coils Picking Oil Coils |

|||

|

Coil Thickness |

3.0~12.0mm |

4.0~16.0mm |

6.0~20.0mm |

|

|

Line Speed |

0~60m/min |

0~50m/min |

0-50m/min |

|

|

Coil Weight |

≤30T(35T) |

≤30T(35T) |

≤30T(35T) |

|

|

Coil I.D |

φ508,φ610,φ760mm |

φ508,φ610,φ760mm |

φ508,φ610,φ760mm |

|

|

Coil O.D |

≤φ2200mm |

≤φ2500mm |

≤φ2500mm |

|

|

Strip Width |

≥100mm |

≥100mm |

≥100mm |

|

|

Number of Strip |

5~20 |

≤5 |

≤5 |

|

|

Slitting Accuracy |

±1.0mm |

±1.0mm |

±1.0mm |

|

|

Blade shaft |

Ф320 |

Ф340mm |

Ф360mm |

|

|

Electrical Control System |

PLC Automatic control |

PLC Automatic control |

PLC Automatic control |

|

Heavy Gauge Slitting Line Specifications

|

COIL/ROLL DETAILS |

Material |

HR, CR, SS, GI, PPGI, |

|

Tensile Strength |

δb≤550Mpa,δS≤260Mpa |

|

|

Coil/Roll thickness |

6-20mm |

|

|

Steel Coil/Roll width |

600-2500(Max) |

|

|

Coil/Roll I.D |

Φ500-760 mm |

|

|

Coil/Roll O.D |

Φ2500mm(Max) |

|

|

Steel Coil/Roll Weight |

35T(Max) |

|

|

Slitter parameters |

knife pivot diameter |

Ф360 mm |

|

Knife pivot material |

40Cr |

|

|

Blades specification |

Φ360mmXφ360mmX20mm |

|

|

Blade material |

6CrW2Si |

|

|

Max slit quantity |

4 pcs (16mm) 8 pcs(8mm)(Customized) |

|

|

Width precision |

≤±0.05mm/2M |

|

|

Other parameters |

Power |

380V/50Hz/3Ph(Customized) |

|

Line speed |

0-60m/min |

|

|

Capacity |

450 KW |

|

|

Whole line Dimension |

45m(L)X10m(W) |

|

|

Line direction |

From right to left(Face to machine) |

|

|

Machine color |

Blue |

Contact

RISHIBN CO., LTD, one of the most professional slitting lines machinery manufacturers from China, which integrated R&D, production, sales and technical service altogether, we provide clients proper slitting machines based on different cutting materials. Welcome your visit.

Company name: RISHBIN CO, LTD.

Company Address: No. 10, Jingshi Rd, Wuxi, China

Phone Number: +86-510-85853379

Mobile/WhatsApp/Wechat: +86-18626315075

Fax Number: +86-510-85853378

E-mail: info@steelslitter.com

Customer Service: service@rishbin.com

Personne à contacter : Ho Chris, 0510 85853379

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de Heavy Gauge Slitting Lines Rechercher dans la catégorie : Divers Rechercher dans la catégorie : gauge, slitting, heavy, lines |

Mercredi 14 septembre 2016

Quantité : 5000 - Prix : 50,00 €

Gate Valves (F7 Type) DIN Standard F7 Gate valves / (Length acc.to DIN EN 558-1,face to face series 26 ) DIN F7 Gate valve DIN Absperrschieber F7 DIN Válvulas de compuerta F7 DIN F7 šoupátko stavební délka dle DIN EN558-1 serie 26 DIN Standard F7 sluseventil (lengde iht. DIN EN 558-1...)

ETM Armaturen

- 59590 - Henri Durre

- 86 577 67953935

Mercredi 14 septembre 2016

Quantité : 5000 - Prix : 50,00 €

Robinet à soupape PN 16/25/40 Acier moulé - Robinet à soupape PN 25‑40 - Construction suivant DIN 3356 - Diamètre : DN15 à DN300 - Chapeau boulonné à arcade - Presse-étoupe boulonné - Tige montante à filetage extérieur - Ecartement suivant EN 558‑1 Série 1 - Raccordement...

ETM Armaturen

- 59590 - Henri Durre

- 86 577 67953935

Samedi 05 juillet 2025

Étanches réutilisables Incontinence Pads Lit bébé de lit (lavable sous l'Pads) Réutilisable Sous pad 430 à 460 gr / m² membrane PU Tissu: 100% polyester capacité d'absorption: 2,6 l / m² 4 couches fonctionnelles laminées l'autre Pour l'incontinence lourde ou moyenne Imperméable Absorber...

Anatolia Textile LTD

- yusufboun

- 34160 - Istanbul

- 00905358815802

Paiement sécurisé