HAI Q Software Platform

HaiQ Warehouse Automation Software Platform

HaiQ is an intelligent software platform that leverages AI algorithms to streamline order fulfillment and inventory management. It serves as the central command for inbound, outbound and inventory management, seamlessly integrating with other devices.

Thorough R&D

Results in rugged software with seamless integrations

Flexible Configuration

Meet the specific demands of the warehouse process

Flexible Scheduling

Support quick integration of multi-type equipment and coordination

Service Oriented Architecture

Modular in-house developed software environment easily adapts to any changes in your business

Intelligent Resource Orchestration

Optimize capacity and space utilization

Continuous Algorithmic Optimization

Achieve operational optimization with AI

Warehouse Execution System (WES)

Hai Robotics Warehouse Execution System (WES) is a smart system that seamlessly interfaces with upstream systems such as ERP, WMS, MES and supports operations such as outbound, inbound, inventory check, stock consolidation and material handling. The system features flexible workstation configuration and operation strategies, such as order grouping, order splitting, wave rule and heat strategy.

* Convenient Upstream System Access

We have experience in implementing projects with well-known ERP and WMS vendors, allowing for flexible field configuration to meet various docking requirements.

* Efficient Configuration and Algorithms

Configure workstation operation rules, support business strategies such as grouping and splitting orders, and have intelligent and efficient algorithms.

* Standard Deployment Plan

It has high availability with automatic switching in case of failure, as well as load balancing and data disaster prevention features.

* Stable and Secure Platform

Capable of processing up to 10,000 external requests per second. The data communication between robots uses encrypted components.

Equipment Schedule System (ESS)

Hai Robotics Equipment Scheduling System (ESS) integrates robots, equipment, and physical environment information into a unified management system, including task management, resource management, and map monitoring and other functions. It receives instructions from upstream systems to control various types of warehouse robots to perform material handling tasks.

* Rich Equipment Integration

Integrated with HaiPick, HaiPort, HaiFlex, conveyors, pick to light system, emergency stop switches, guard doors, etc.

* Multi-type Robot Mixed Field Operation

Mixed scheduling of multiple types of AGVs, such as scheduling HaiPick, HaiFlex.

* Efficient Task Linking

Multiple devices work in parallel to complete related tasks, reducing mutual waiting.

* Large-scale Robots Scheduling

Capable of scheduling over 1000 robots.

Data Platform

The Data platform collects and integrates data from various systems, including WES, ESS, and Robots. It centralizes the processing of data related to warehouses, robots, equipment, personnel, and commodities.

Using intuitive and easy-to-understand visualization interface, the value of data analysis can be demonstrated, such as warehouse traffic, work efficiency, providing management and decision-making basis for business managers.

Simulation Platform

The Simulation Platform creates a virtual warehouse by inputting map files, order files, inventory files, and demand configurations. By incorporating the actual customer scenario's demand parameters, the platform conducts a 1: 1 simulation.

Using the simulation results of robot operations, the project plan is swiftly verified, and strategies and on-site configurations are promptly adjusted to promote the best solution. This helps customers achieve maximum project benefits.

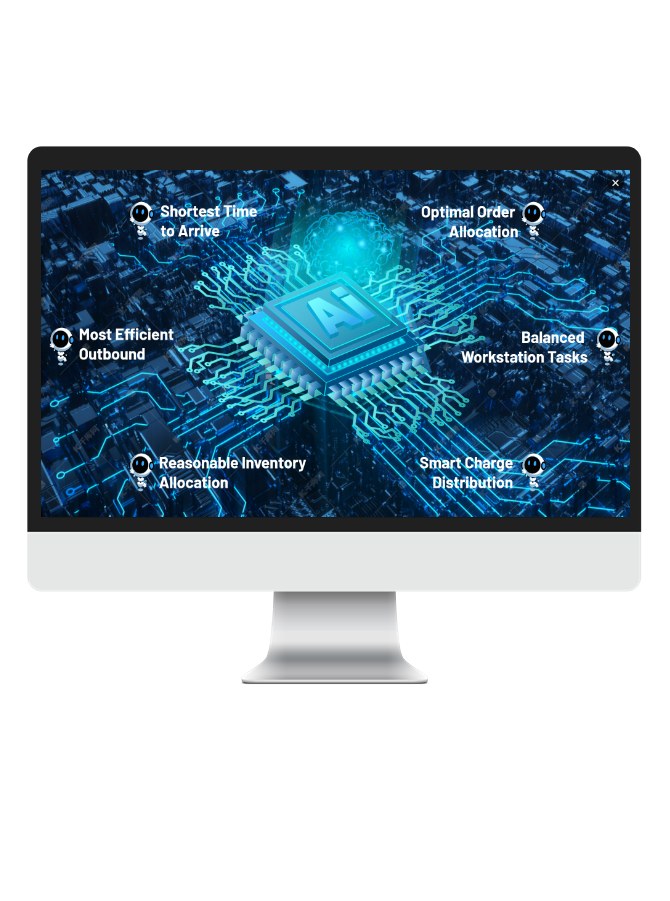

AI Algorithm Platform

As the intelligent brain of the HAI Q system, the AI Algorithm Platform is responsible for the analysis, computation and decision-making of various systematic scenarios. Intelligent analysis, high-efficiency computing and smart decision-making remarkably improve the operating efficiency of the system to the greatest extent.

* Order Allocation Algorithm

Select orders from the order pool and assign them to workstations to maximize order timeliness, picking efficiency, and workload balance.

* Task Allocation Algorithm

Assign tasks to robots to ensure optimal transport efficiency and timely completion of transport tasks.

* Path Planning Algorithm

Minimize robot travel distance, achieve robot avoidance, queueing, and other actions, and reduce workstation downtime.

* Charging Algorithm

Provide stable and sufficient robot transport resources to ensure efficient completion of warehouse operations.

If you want to know more applications of our intelligent warehouse management system and robot management system, please visit our website.

Hai Robotics is the pioneer and leader in warehouse automation and robotics systems. The company is committed to providing efficient, intelligent, and flexible automation solutions through advanced robotics and AI algorithms creating value to every warehouse and factory.

Personne à contacter : hai robotics , 0086 755 23208112

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de HAI Q Software Platform Rechercher dans la catégorie : Informatique Rechercher dans la catégorie : software, platform |

Jeudi 03 juillet 2025

Unitronics Samba – Automate Control Engineering Ltd. (winston@automate-ace.com) Still using text display? it's SAMBA time! Improve your competitive advantage. Great look - incredible price. System integrators and OEMs often develop applications that require PLC control, but that...

Automate Control Engineering Ltd.

- automatehk

- 999077 - Hong Kong

- +85 2 23 42 72 76

Vendredi 23 mai 2014

Quantité : 1 - Prix : 750,00 €

frigo mural ( crèmerie , charcuterie , fromagerie , boisson ) idéal pour magasin d'alimentation général , supérette dimensions 1m33 équipé de 3 étages et le sol système de refroidissement ventille gaz conforme aux normes CE prix Htva , sauf zones Europe ( TVA intracommunautaire...)

MCFRANCE SAS

- 59200 - Tourcoing

- 07 81 55 30 28

- 06 51 11 02 96

Mercredi 10 septembre 2014

Quantité : 1 - Prix : 234 000,00 €

2000 HEIDELBERG CD 102 -5 Couleurs: 5 Taille: 72 x 102 cm Âge: Count 2000 (Poster Drupa modèle) Impression: 105 millions d' Équipement: CP 2000 - AUTOPLATE - PRESET - Infra Sèche-Rouge - ALCOLOR mouillage - Technotrans centrale de réfrigération - Toutes les laveuses automatiques (blanchets...)

Delfina International Ltd

- PR4 5HY - Lancashire

- +447031987697