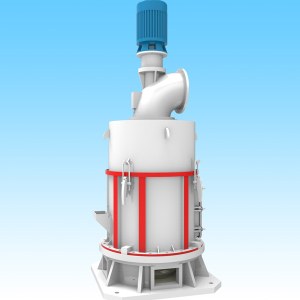

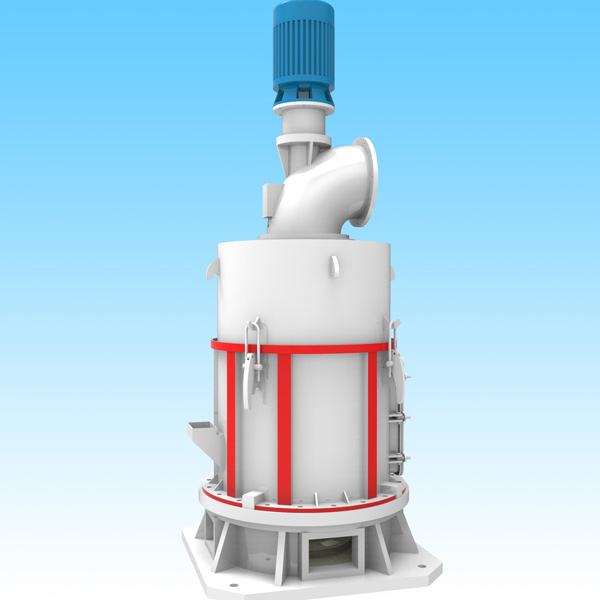

GKW970 Micro Powder Mill

Quantité : 1 Prix : undetermined

GKW970 Micro Powder Mill is a new modified superfine powder mill developed by our R&D team for grinding 400-1250 mesh powder based on client's need.It is mainly used for grinding non-flammable and non-explosive materials, whose hardness below seven Moh's hardness following humidity below 6%, such as dolomite, calcite, marble, barite, limestone etc. As the top option of grinding 400-1250 mesh powder, CKW micro powder mill is featured with high capacity, wide application, energy-saving, easy operation. Its total installed power is 132KW. If grinding calcite, the capacity is 1.5 t/h for 1250mesh powder.

Technical & Structural Benefits of GKW970 Micro Powder Mill:

1. Finished particle size 400 mesh -1250 mesh (stepless adjustment); 2. Breakthrough hard materials and powdery materials, and grind the materials such as talc and fly ash; 3. Low cost of equipment wearing parts; 4. Convenient equipment maintenance, maintenance & replacement of wearing parts;5. Low energy consumption and high output, for users to create better economic results; 6. Energy conservation and environmental protection.

|

Model |

Max Feeding Size |

Product Fineness (mash) |

Capacity |

Total Installed Power |

|

GKW970 |

≤10mm |

400-1250mesh |

500-3200kg/h |

120kw |

|

GKW1270 |

≤10mm |

400-1250mesh |

1000-6500kg/h |

225k |

Safe Regulations for Operation of GKW970 Micro Powder Mill:

(1) Persons who are familiar with the machine's instruction book and its characteristics are permitted to operate it.(2) Strick shift system is required.It is necessary to have recording book that machine's operation (including running and lubricating the machine, temperature increase at all various parts and seal etc.), output per shift, product quality, voltage, current and the arising fault etc. Should be registered in detail.(3) Starting and stopping must be carried out strictly depending on the regulations in Chapter "Applications".(4) Working place must be kept tidy and clean.No piling is allowed in the powder grinding machine room.After working finished, the machine should be stopped and its surface is wiped clean by each shift.(5) Repairing, refilling and wiping are forbidden while the machine is working.(6) Working with the fault is not allowed.The machine must immediately stop down for maintenance once troubles are found.Re-starting is only allowed after repair.

Personne à contacter : Zeng Ralap , 0773 6812095

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de GKW970 Micro Powder Mill Rechercher dans la catégorie : Bâtiment Rechercher dans la catégorie : gkw970, micro, mill, powder |

Mercredi 04 juin 2025

Quantité : 500 - Prix : USD0.5/pc

American Pinch clamps Factory in China The Supplier of one of Fortune top 500 Machine, Technology, Quality from USA SAE Type SEC Stainless Steel Single Ear Pinch Clamps KSL7123 Beverage, automotive, marine, motorcycle and industrial pinch clamps. The patented 300 Series Stainless...

King Seal Fastener Technology(Anhui) Co., Ltd.

- 233010 - Bengbu

- 86 552 4193229

Vendredi 22 novembre 2013

Quantité : gros quant - Prix : contacte moi svp

bonjour tout le monde. La société les deux frére Industry est spécialisée dans la remise en marché de marchandises industrielles de tous domaines. Nous sommes donc intéressés par l'achat de tels articles autant en grande qu'en petite quantité. Il peut ainsi s'agir d'articles neufs...

les deux fréres

- 1060 - bruxelles

- +32 4 84 70 13 68

Mercredi 02 octobre 2013

Quantité : 1000 - Prix : 25USD

1. Water-repelling fabric to help keep you stay lightweight and dry 2. Flywire strength resists stretch around the neck, so it holds its shape. 3. Strategic ventilation over major heat zones helps keep you cool. 4. Zoned stretch fabric at the sides is tailored for a precise fit and movement...

cheap nba jersey supply

- 95117 - San Jose

- (408) 666 9289

Paiement sécurisé