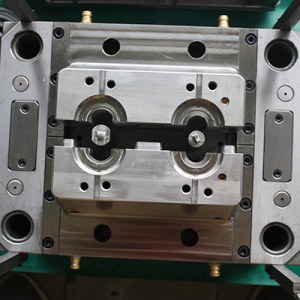

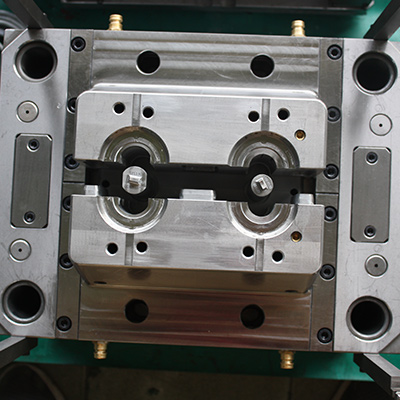

Family Mould

What is the family mold?

A mold that can only produce one product at a time is called a single-cavity injection mold. If a mould is used to produce two or more plastic parts at a time, multi-cavity injection, if the parts are different, such a mold is called family mold.

The plastic parts produced by the single cavity mold have high precision, easy control of process parameters, simple mold structure, low mold manufacturing cost and short cycle time. However, the productivity of plastic molding is low, and the cost of plastic parts is high, which is suitable for large plastic parts, high precision requirements or small batches and trial production.

The plastic parts produced by the multi-cavity mold or family tool injection molding have low precision, it is difficult to control the process parameters, the mold structure is relatively complicated, the mold cost is high, and the cycle time is longer. However, productivity is higher, the cost of plastic parts is lower, and it is suitable for large quantities and long-term production of small-sized plastic parts.

The number of cavities is often determined by factors such as budget, clamping force, plastic part structure, and injection volume.

When designing a multi-cavity mold, one method is to determine the model of the injection molding machine, and then calculate the number of cavities according to the technical parameters of the injection molding machine and the technical requirements of the plastic parts; the other method is based on the requirements for production efficiency and the structure of the part require the number of cavities to be determined, and then choose the proper injection molding machine or check the existing injection molding machine.

We normally make the multi-cavity mold with 2 cavities, 4 cavities, 8 cavities, 16 cavities, 32 cavities, 48 cavities, etc. For family mold, we normally make at 1+1 cavities, 2+2 cavities, 4+4 cavities, 8+8 cavities, we can find the numbers are always double. Family mold help to molding different plastic parts in the same mould, this solution saves tooling and molding cost. For most family mold, the plastic part is in the same material & similar size, HanKing Mould will help customers to analyze the possibility to make the best economic plastic injection mould.

Personne à contacter : Yoyo Tang, 86 13798257041

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de Family Mould Rechercher dans la catégorie : Habillement / Mode Rechercher dans la catégorie : mould, family |

Mercredi 26 décembre 2012

Quantité : 999999 - Prix : 0,00 €

disponible pour sem 51 et 52 2012 pomme de terre : 15 tonnes petit pois: 6 tonnes oignon: 5 tonnes piment vert piquant : 15 tonnes féve: 15 tonnes amande : 5 tonnes huile de figue de barbarie : 200 litres huile d'amande douce : 480 litres henné poudre : 800 kg huiles d'olive...

SAHELFRUITS

- 4002 - Sousse

- +21 6 97 78 70 00

- +21698209977 \ +33699913843

Samedi 18 octobre 2014

Quantité : No Limit - Prix : 200 USD

Level 10 is a professional scooter parts manufacturer and supplier in Taiwan. We specialized in manufacturing scooter parts with high quality and competitive price to meet customer's needs. The oil filter is OEM replacement and paper is from Germany. Model:scooter Material:paper...

Pai Weih Enterprise Co., Ltd.

- level10

- 71043 - Tainan

- +88 6 62 33 78 28

Dimanche 28 avril 2013

Maxi Protection vous propose de nombreux produits pour vos habitations ou bien votre entreprise. Vous pourrez y trouver des extincteurs, des détecteurs de fumée ou de gaz, des trousses de secours,et autres matériels d'incendie. ----- ----- ----- ----- ----- ----- ----- ----- ---...

Maxi Protection

- maxisarl

- - Rabat

- 00212537202632

- 00212661343484

Paiement sécurisé