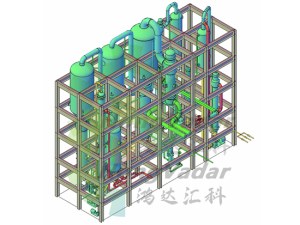

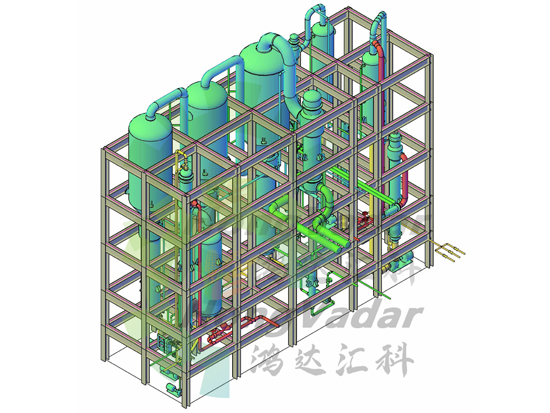

Evaporator System

HongVadar has all kinds of engineering and technical personnel with more than 30 people, including 8 senior designers, who had serviced for the international famous enterprise like Cargill, DA CHENG GROUP, and a number of well-known domestic and design institute; who has also played in MEIHUA GROUP, EPPEN, Yihai Kerry and other international well-known fermentation enterprise and who has also played in the American Komline-Sanderson company. HongVadar has rich engineering, equipment supply, and production experience in starch, all kinds of sugar , and ethanol production line.

Multi-effect TMR Evaporator System

HVD-EV-T series TVR vacuum evaporation equipment is a kind of mechanical recompression evaporator condenser system. The multiple vapor recompression evaporator working principle is using secondary steam many times according to the theory of vacuum low-temperature evaporation to save steam energy. According to the evaporation capacity and energy-saving requirements, it can be divided into single effects, two effects, three effects, four effects, five effects, and so on. The structure is divided into falling film, forced falling film, forced circulation, and so on.

Multiple effect evaporators are used to evaporate heat-sensitive, high concentration, high viscosity, and corrosive materials, and suitable for concentration of corn steeping liquid and maltose syrup in starch & glucose industry, fruit juice and flavored semen in the food industry, liquid milk in the dairy industry, sugar juice in the sugar industry and distiller's grains filtrate in the industry. As one of the reliable evaporation equipment manufacturers, we make different types of multiple effect evaporator for sale, such as single effect evaporator and forward feed multiple effect evaporator with the best evaporation machine price.

Main feature of Multi-effect TMR Evaporator System

- The whole compressor evaporator condenser system is designed reasonably and beautifully, running stably, highly efficient and energy-saving, and low steam consumption.

- High concentration ratio, falling film evaporation, so that the viscosity of the material liquid easy to evaporation, and short time concentration.

- Special design, realize switching efficiency through simple operation to adapt to the production of different products.

- Low evaporation temp, suitable for the concentration of heat-sensitive materials.

- High heat transfer coefficient and high evaporation rate, which can prevent the "drywall" phenomenon.

- High separation effect and greater flexible operation.

- Compact structure, small floor area, and simple & smooth layout.

- In and out of the material continuously. The material liquid can reach the required concentration after passing through the equipment once.

- If the material needs continuous sterilization treatment, the sterilization, and concentration of two processes can be completed at one time.

- Equipped with CIP cleaning pipeline. The calandria type evaporator can be cleaned on the spot. The whole equipment is easy to operate without dead Angle.

- The power control is realized by the control cabinet, and the automatic control system can be installed according to the user's requirements.

- Special pump, reliable seal, stable performance, little maintenance, and smooth operation.

MVR Evaporator System

HVD-EV-M series MVR compressor evaporator condenser system compresses the secondary steam generated by the steam according to the principle of mechanical compression, so as to raise its temperature to a certain extent and return the heating system to replace the raw steam as the heat source of the heater, so as to make full use of the waste stream, recover the latent heat, improve the thermal efficiency, and achieve the purpose of saving steam energy. At the same time, mechanical vapour recompression evaporator also reduces the demand for external cooling resources, reduces energy consumption, and reduces pollution. This product of mvr evaporator design and technology is mainly used in multi-effect evaporation and crystallization equipment.

Evaporator System Technical Parameters

Multi-effect TMR Evaporator System Technical Parameters

|

Model |

Evaporation capacity |

Steam consumption kg/h |

Each effect vacuum, mmHg |

Each effect temp. ℃ |

Steam pres. |

Feed DS,% |

Discharge DS, % |

||||

|

1st effect |

2nd effect |

3rd effect |

1st effect |

2nd effect |

3rd effect |

||||||

|

HVD-EV1.0-T |

1000.0 |

250-300 |

0.0 |

448.0 |

640.0 |

99.0 |

76.0 |

53.0 |

0.6-1.0 |

6-7 |

42-48 |

|

HVD-EV3.0-T |

3000.0 |

750-900 |

|||||||||

|

HVD-EV4.5-T |

4500.0 |

1200-1350 |

|||||||||

|

HVD-EV6.0-T |

6000.0 |

1600-1800 |

|||||||||

|

HVD-EV9.0-T |

9000.0 |

1500-2700 |

|||||||||

|

HVD-EV12.0-T |

12000.0 |

3000-3600 |

|||||||||

|

HVD-EV15.0-T |

15000.0 |

3750-4500 |

|||||||||

|

HVD-EV20.0-T |

20000.0 |

5000-6000 |

|||||||||

|

HVD-EV25.0-T |

25000.0 |

6250-7500 |

|||||||||

|

HVD-EV30.0-T |

30000.0 |

7500-9000 |

|||||||||

|

HVD-EV50.0-T |

50000.0 |

12500-15000 |

|||||||||

Comparison and Evaluation Table of MVR and Five-effect Evaporator

|

Evaporation type |

Five-effect evaporator |

MVR evaporator |

|

|

Evaporation capacity × evaporator qty. |

100tph×1set |

100tph×1set |

|

|

Energy consumption |

Steam, t/h |

27.4 |

5.56 |

|

Pump electricity consumption, KWH |

465 |

430 |

|

|

MVR electricity consumption, KWH |

0 |

1890 |

|

|

Cooling water consumption, m3/h |

1300 |

300 |

|

|

Annual energy consumption |

Steam price, RMB/ton |

180 |

|

|

Electricity price, RMB / KWH |

0.55 |

||

|

Running days, days / year |

330 |

||

|

Annual steam consumption cost around, ten thousand RMB / year |

3900 |

790 |

|

|

Annual power consumption cost around, ten thousand RMB / year |

200 |

1000 |

|

|

Annual energy consumption around, ten thousand RMB / year |

4100 |

1800 |

|

|

|

Main material |

304/316L |

|

|

The payback period for the investment of fixed assets that are overinvested due to the use of MVR evaporator |

Around 230 days |

||

Other Agriculture Processing Product

Let Us Know How We Can Help

Fill out the form below to get your project rolling.

Personne à contacter : Li Danny, +13 8 11 96 92 27

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de Evaporator System Rechercher dans la catégorie : Divers Rechercher dans la catégorie : evaporator, system |

Mercredi 10 septembre 2014

Quantité : 1 - Prix : 234 000,00 €

2000 HEIDELBERG CD 102 -5 Couleurs: 5 Taille: 72 x 102 cm Âge: Count 2000 (Poster Drupa modèle) Impression: 105 millions d' Équipement: CP 2000 - AUTOPLATE - PRESET - Infra Sèche-Rouge - ALCOLOR mouillage - Technotrans centrale de réfrigération - Toutes les laveuses automatiques (blanchets...)

Delfina International Ltd

- PR4 5HY - Lancashire

- +447031987697

Vendredi 23 mai 2014

Quantité : 2 - Prix : 850,00 €

buffet réfrigérée en état d'occasion j'ai deux pièces disponible ( identique ) équipé de roulette système de refroidissement statique pour plus d'information : gaz conforme aux normes CE prix Htva , sauf zones Europe ( TVA intracommunautaire ) pour plus d'information : M...

MCFRANCE SAS

- 59200 - Tourcoing

- 07 81 55 30 28

- 06 51 11 02 96

Samedi 21 novembre 2015

Spécifications et devis pour notre granulés de bois de la meilleure qualité. NOM DU PRODUIT: granulés de bois Forme: Bâton Couleur: jaune clair Type de bois: pin, chêne, hêtre et épicéa. Diamètre: 6-8 mm Longueur: 10-12 mm Cendres: 0,6% max Humidité: 8% max Calories: 4200-4600KCAL...

A & B IMEX

- 31675 - Bückeburg

- +49 (0)5722 2891328

Paiement sécurisé