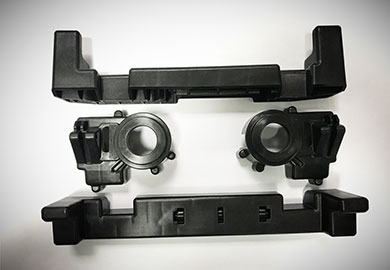

Electronics Product Part

Prix : 100USD

Electronics Product Part

With the fast growth in the electronic industry, the demand for injection molding electronics is much higher. The injection molding electronics can be intricate or simple.

Intricate injection molding electronics can be economical because they combine many parts into one piece which saves the cost of different types of separate pieces. As a professional electronics plastic manufacturer, GM-TECH provides injection molding electronics such as mobile phones, computers, and sophisticated connectors.

Features of injection molding electronics parts

Be able to use a different plastic simultaneously

As a reliable plastic mold technology inc, we can utilize different types of plastic at the same time by using injection molding electronics. This can be achieved with the help of co-injection molding.

Lower the manufacturing cost

Plastic injection mold is an intelligent process with some automatic machines which reduce manufacturing plastic mold cost.

Form the finished appearance

Custom plastic injection molding electronics make sure the parts produced are near to the finished produces. Thus, it hardly takes any time to arrange the rest of the work.

The Specification of injection molding electronics Product Part

|

Part material |

PA66 + 30gf |

|

Cavity |

1 |

|

Mould steel |

1.2343 |

|

Mould steel |

1.173 |

|

Mould life |

100W |

|

Mould standard |

HASCO |

|

Mould structure |

3 sliders |

|

Exporting country |

Germany |

|

Leadtime |

5 weeks |

|

Mould quality customer satisfaction |

96% |

|

FAI pass rate |

99% |

|

Project cooperation service customer satisfaction |

98% |

How do Injection Molding Electronics Parts Work?

The series of events that occur during the injection molding electronics molding process is called the injection molding cycle. When the mold is closed, the polymer of plastic molded products is injected into the mold cavity. Once the cavity is filled, the pressure is maintained to compensate for the shrinkage of the plastic injection molded part material. In the next step, the screw rotates to give the screw before the next lens. This allows the screw to retract when preparing for the next stitch. Once the part is sufficiently cooled, the mold opens and the injection molding electronics are ejected.

Personne à contacter : Kevin Shaw, 0086 0769 8535 7333

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de Electronics Product Part Rechercher dans la catégorie : Divers Rechercher dans la catégorie : part, electronics, product |

Dimanche 09 septembre 2007

Prix : $134.99

Product Functions: * 100% Brand New High Quality Digital/Video/PC Camera Webcam Music Player * Intelligent CMOS sensor can test objective distance and decide flash light intensity automatically * 3 mega pixels resolution & 3 inch LTPS TFT color LCD screen * Internal 32MB flash memory...

Sourcingmap Company Ltd

- larryxiao

- - hongkong

- +85 2 24 89 93 31

Samedi 09 mai 2015

Quantité : New - Prix : 0,01 €

FiberTek IP66 rated stainless steel outdoor wall mount patch panels is designed for either to support direct termination or fusion splicing of the fibers. The stainless steel material and great Ingress Protection from dust and water making it suitable for installation in harsh outdoor...

FiberTek Pte Ltd

- Fibertek

- 408705 - MacPherson

- 65 62801966

- +6562801966

Mercredi 24 décembre 2014

Quantité : 100 000 - Prix : USD 5000 / Tonne

Cuivre cathode 99,99%. Travailler avec nous c'est éviter la fraude et la perte de temps. Aucun frais d'avance. Vous Recevez et Confirmez le produit avant Paiement. Nous n'exigeons qu'une preuve de fonds. Visite possible. Qu'attendez-vous pour commander ? Localisation : 06 BP 1384...

HUAFU

- 00229 - COTONOU

- 96234560

Paiement sécurisé