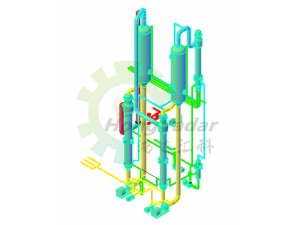

Continuous Evaporative Crystallization System

Quantité : 1-100 Prix : USD 50000-5000000

HVD-CC-T series continuous crystallization equipment system is designed and developed by our factory with patent applied.

Core Of Evaporative Crystallization Process Control

Design enough long crystal time according to crystal characteristics to create an environment conducive to the growth of crystal structure.

Continuous crystallisation equipment adjusts the direction of materials, control the number of microcrystals, realize the whole process control of seed generation, seed growth, elimination of microcrystals, growth of qualified particles, and timely discharge of qualified particles.

Most businesses take crystallization as the process of concentration. It is believed that the concentration reaches supersaturation, the crystal forms naturally, and there is no awareness and measures to control the crystal quality. The control of the crystal purpose is ignored, and the influence of crystallization on separation and drying is not fully considered, which makes the subsequent section treatment more difficult due to the crystallization. Therefore, the purpose of crystallization is to improve the overall yield and product quality and reduce the product production cost by continuous crystallization equipment.

Characteristics Of Evaporative Crystallization System

Crystallisation and evaporation system is used for products with general requirements on crystal shape and size and can achieve high concentration discharging.

According to the characteristics of materials and the evaporation capacity, Crystallisation and evaporation system can be designed as a single-effect or multi-effect evaporative crystallization system.

The unique design of the continuous cooling crystallizer can meet the intermittent crystallization, semi-continuous crystallization, and continuous crystallization system. Continuous oscillatory baffled crystallizer can meet the continuous feed, continuous discharge process requirements.

The whole evaporation vs crystallization process system evaporates under the vacuum condition, with relatively low temp, fast evaporation speed, high evaporation concentration, and the relatively high viscosity of the liquid material is not easy to scale or block, which can achieve the maximum crystal ratio under the same energy consumption.

HongVadar relies on professional design, strict production management, the fine processing procedure, provides high efficiency and energy saving and circulating liquid evaporator crystallizer system for the customer. The manufacturing factory has passed the international ISO9001 quality system certification, and with the design and manufacturing capacity of pressure vessels. Customers can choose Chinese GB, International ISO, American standard ASME, European standard PED and other standards for equipment design and production according to their needs.

Continuous Evaporative Crystallization System Technical Parameter

|

Model |

Ev capacity |

Steam consumption kg/h |

Each effect vacuum, mmHg |

Each effect temp. ℃ |

Steam pres. |

Feed DS,% |

Discharge DS, % |

||||

|

1st effect |

2nd effect |

3rd effect |

1st effect |

2nd effect |

3rd effect |

||||||

|

HVD-CC1.0-T |

1000.0 |

330-400 |

300 |

510 |

750 |

85 |

76.0 |

55 |

0.5-0.6 |

5-6 |

55-65 |

|

HVD-CC3.0-T |

3000.0 |

990-1200 |

|||||||||

|

HVD-CC4.5-T |

4500.0 |

1485-1800 |

|||||||||

|

HVD-CC6.0-T |

6000.0 |

1980-2400 |

|||||||||

|

HVD-CC9.0-T |

9000.0 |

2970-3600 |

|||||||||

|

HVD-CC12.0-T |

12000.0 |

3960-4800 |

|||||||||

|

HVD-CC15.0-T |

15000.0 |

4950-6000 |

|||||||||

|

HVD-CC20.0-T |

20000.0 |

6600-8000 |

|||||||||

If you want to know more details of wheat starch processing plant, please leave us a message, and we will provide you professional consultance.

Personne à contacter : Li Danny, +13 8 11 96 92 27

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de Continuous Evaporative Crystallization System Rechercher dans la catégorie : Biens d'équipement Rechercher dans la catégorie : system, continuous, evaporative, crystallization |

Thursday 28 September 2017

Quantité : as per ite - Prix : based on Qty

Dear Sir, We deal with Building Materials & Machine Spares since 1987 and LED Lighting and Solar Products since 2014. Our Product Range : Structural Steel : MS Angles, Channel, Beams, Flat Bar, Plain sheets, Chequered plates,Round Bars. Aluminum: plain sheets, Angles, Flat Bars...

Rashid Essa Building Material Co. LLC

- sajj

- 971 - dubai

- 04 2563282

- 971 55 6995965

Tuesday 23 September 2014

Prix : 31,00 €

Solar Pumpe Teichpumpe Solarpumpe Solar Wasserspiel Brunnen Gartenteichpumpe Wasserbrunnen Pumpe Die Solar Wasserbrunnen ist ein universell einsetzbares Pumpenset für kreative Gärtner und Teichbesitzer. Das Solar Pumpenset ist für den Einsatz im Aussenbereich in Gartenteichen konstruiert...

365buy

- 3600 - Thun

- 07 62 07 63 81

Wednesday 14 September 2016

Quantité : 5000 - Prix : 100,00 €

Corps Acier A216 WCB & GS-C25 & 1.0619 & GP240GH - Clapet Inox 420 - Siège Inox 420 - Soufflet Inox 321 - Presse étoupe Graphite Tige et volant montants tournants - Chapeau et presse étoupe boulonnés - A brides RF PN16/ PN25/40 - Commande par volant fonte - Peinture...

ETM Armaturen

- 59590 - Henri Durre

- 86 577 67953935

Paiement sécurisé