CNC Horizontal Boring Mill

SEALION supplies Horizontal Boring Mill for sale both 110mm and 130mm spindle, with or without the back column. Great cost performance is the main advantage of this hydrostatic moving column boring machine, it is always your best choice.

Application Fields of CNC Horizontal Boring Mill

Energy

Earth Moving

Die&Mold

General Machining

Engines

Features of Horizontal Boring Mill For Sale

The TPX6111/6113 horizontal milling and boring machine produced by our company Sealion boring mill manufacturers is the finishing equipment in general machines.

It has the functions of drilling, reaming, boring, milling and turning threads, and so on. In addition, there is a facing head in front of the spindle, and the slider in the facing head can move to get radial feed. Therefore, it can bore large size holes, turning circle and plane, and cutting grooves.

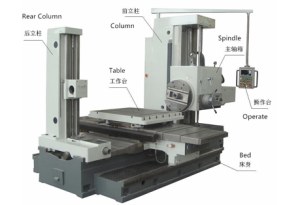

CNC horizontal boring and milling machine is made up of bed, A-post, headstock, longitudinal saddle, and transverse saddle, worktable, D-post, and hammer. Each part moves as the headstock moves vertically along the guide of the A-post, and the worktable can move longitudinally, transversely, and do the rotational motion. CNC horizontal boring machine for sale, contact us for more info.

How to Use Horizontal Boring and Milling Machine

Any horizontal cnc boring bar has three key components: spindle, anchor and blade. The anchor point is simple-it is the point where the steel bar is connected to the main body of the rolling mill. The spindle rotates under power, turning the tool and generating the force required to cut into the workpiece. The indexable insert is the retractable part of the spindle, which is used to slowly advance the tool into the workpiece.

One of the key ideas of using a boring and milling machine is the idea of overhang. The longer the index, the farther the tool is from the anchor point, and the weaker the connection. Tolerances become less stringent, cutting becomes less accurate, and the chance of failure becomes greater.

Despite the risks, horizontal cnc boring and milling machines provide greater flexibility for cutting larger workpieces. The operator can minimize the risk of overhang by repositioning the workpiece as needed, keeping the overhang short.

In many cases, the blade itself is a knife; it will be made of grinding or cutting materials; a popular type is a concrete cemented carbide. The size and shape of the blades also vary, so operators can use their boring machines to create different geometries and surface finishes.

Working of Horizontal Boring Machine

The horizontal boring machine remains stationary and the boring tool rotates. Use horizontal boring bars and tools to drill holes. When drilling, fix the boring tool on the spindle, and adjust the tool on the drill rod to the specific required size. The main factors for drilling are the required drilling length and spherical size.

Horizontal Boring Machine Parts and Functions

1. Bed

The bed is made of cast iron, fixed on the ground, and placed where it can support tables and pillars.

2. Column used to support the headstock and end

The column is also made of cast iron to provide support for the headstock that moves horizontally up and down. Lateral support columns or guide rails are placed on the bed.

3. Headstock

The spindle box is placed on the column support, and the operating tool is fixed. The headstock moves up and down to fix the operating tool at the required working height.

4. Table

The worktable is used to support the workpiece during boring operations and provides T-shaped positions for clamping different parts of the hydrostatic boring machines.

5. Saddle

The saddle is the part that allows the work item to move in longitude motion on the bed. The saddle also controls the speed of movement by manual or motor drive.

6. Boring Bar

Boring bars are used to fix the tool, spindle and column for boring operations. Support depends on the level of drilling operation, such as hole diameter, deep hole or short deep hole.

Personne à contacter : Steven Liu, 021 57880511

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de CNC Horizontal Boring Mill Rechercher dans la catégorie : Pro / B2B Rechercher dans la catégorie : boring, horizontal, mill |

Jeudi 20 juin 2013

Quantité : 1 - Prix : 10000 USD

Chaudière en acier inoxydable ET EQUIPEMENTS NOS ZONES DE PRODUCTION INDUSTRIE ALIMENTAIRE • bonbons durs et mous LIGNES DE PRODUCTION • CHOCOLAT LIGNES DE PRODUCTION • HALVA, confiture, miel, RAISIN LIGNES DE PRODUCTION la mélasse • TAHINI, graines de sésame USINES...

TURKON EXPORT LTD.

- 42050 - KONYA

- +905353265862

Dimanche 15 décembre 2024

Quantité : 50000 - Prix : dépend du quantité

De grande qualité, agréable au toucher, légère, douce, Ultra-absorbante et sèche vite : Votre Fouta vous suivra partout, dans votre salle de bain, à la piscine, à la plage, sur le transat, le bateau ou en paréo, entourant les bébés, les enfants à la sortie du bain. Dans vos bagages...

artisanat Tunisien

- med.SGHAIER

- 5099 - Tunisia,Monastire

- +21 6 26 10 49 12

- 26104912

Jeudi 12 mars 2015

Quantité : 1000 - Prix : 10 DH

BONJOUR JE VEND UN STOCK SUR COMMANDE PRODUIT UTILE POUR LES AUTO PC ET AUTRE NETOYAGE Localisation : al massira 1 n°367 temara, 10000 rabat, Personne à contacter : Marouane El arradi, +212655656875

arganda

- marouane88

- 10000 - rabat

- +212655656875

Paiement sécurisé