Bi-center bit for Mining Machinery and abrasive formation

Quantité : 10000 Piec Prix : 150-10000 USD

Overview of Bi-center Bit

This type of bicenter bit mainly used for medium to medium-hard compressive and abrasive formation, it has medium and high-density parabolic crown and heavy cutters density for the bit has good impact resistance and anti-abrasive, high wear-resistant diamond gauge, the wholesale bi center drill bit has a longer service life.

In directional applications, bi center bit performance usually presents performance challenges in terms of efficiency versus power availability and dynamic issues.

Cangzhou Great Drill Bits Co.,Ltd. designed the bi-center bit to enlarge the wellbore diameter, to replace under reaming, to help control rouble zones and for expandable tubular.

Bi-center Bit Design

As one of drill bit manufacturers, we designed this bi-center bits with close attention to hydraulic optimization to improve chip removal and ensure effective tool cooling. In addition to the improved hydraulic configuration, the cutting configuration was carefully studied to ensure that it is both effective and balanced - not only on conventional components but also when used in combination with a bent-case motor. This design concept of bi center bits combined with GREAT's wide range of PDC cutters grades and geometries results in a bi-center drill with excellent drilling performance.

The Specification of Bi-center Bit

Here are the bi center drill bit sizes.

|

Reaming Size |

12 1/4" |

Nozzle Qty |

3NZ |

|

Pass Thru Size |

10 1/2" |

Gauge Lenghth |

2.5" |

|

Blade |

5 |

Connection |

6 5/8" API REG |

|

Primary Cutter Size |

16mm |

Make up Torque(kN.m) |

51.7~56.9 |

|

Rotary Speed(rpm) |

60~260 |

Weight on Bit(KN) |

30~260 |

|

Max.WOB(KN) |

180 |

Flow Rate(lps) |

35~70 |

The Advantage of Bi-center Bit

Our Bi-center bit is one piece body, you will never worry about broken.

We can adjust the bi-center diameter according to your casing diameter. Generally speaking, the bigger pilot bit has a smaller reaming size. The smaller pilot bit has a bigger reaming size.

GREAT's casing protection features cutting structure that provides a reliable way to drill, protecting both the cutting structure inside the casing and the casing itself.

During the design process, the pilot and reamer cutting structure of this PDC bit are force balanced as a single unit. This provides the bi center drill bits increased drilling efficiencies in both vertical and deviated wells.

Personne à contacter : Wang Weiwei, +86 13161769999

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de Bi-center bit for Mining Machinery and abrasive formation Rechercher dans la catégorie : Biens d'équipement Rechercher dans la catégorie : mining, formation, abrasive, center, machinery |

Sunday 14 August 2016

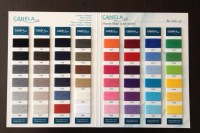

Cher Monsieur, Nous sommes producteur de fil de la Turquie. Nos produits peuvent être utilisés dans des chaussettes productions. Tout à propos de Canela Textile; Canela Textile dont le siège est à Istanbul, la Turquie a été fondée en 1985. Canela tenir une position forte sur...

canela textile

- 34035 - istanbul

- 00902124931597

Friday 16 May 2014

Quantité : 5000000pcs - Prix : $0.25-5/pc

Profil D'entreprise: Nous sommes spécialisé à l'élaboration et produire pièces d'injection plastique et moules d'injection pour les appareils électriques, appareils ménagers, ordinateurs, dispositifs de télécommunications appareils pharmaceutiques, salle de bains accessoires...

Xiamen Karo Co.,Ltd

- karoplastic

- 361002 - Xiamen

- 0086 592 5135406

Thursday 03 October 2019

Prix : 56 €/m²

Bâtiment métalliques modulaires toutes dimensions, temporaires ou définitifs. Bâtiments en kit extensibles et entièrement démontable. Structure métallique principale composés de profils de type " C" ou " SIGMA " formés à froid et galvanisés, structure secondaire sur couverture et...

HADDOUCHE

- 33140 - CADAUJAC

- 06 72 47 36 41

- +33 6 72 47 36 41

Paiement sécurisé