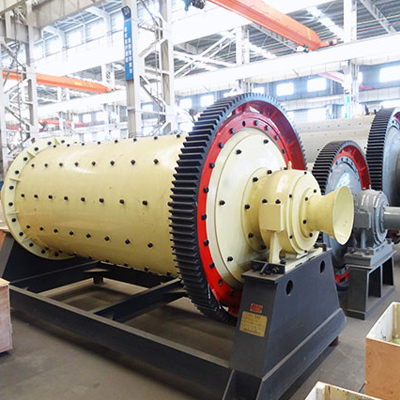

Ball Mill

The Handling Materials and Main Types of Ball Mill:

Ball mill is a key equipment for grinding materials, widely used in powder-making production line such as cement, silicate sand, new-type building material, refractory material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics, etc.

Ball mill can grind various ores and materials with the dry type or wet type. There are two kinds of ball mills, grate type and overfall type due to different ways of discharging material.

The Interior Structure of Ball Mill:

The industrial ball mill is composed by feeding part, discharging part, turning part and driving part (reducer, small driving gear, electric motor and electric control). The quill shaft adopts cast steel part and the liner is detachable. The turning gearwheel adopts casting hobbing process and the drum is equipped with wear-resistant liner, which has good wear-resistance. The machine is in stable and reliable working condition.

Moreover, according to different materials and discharging methods, there are dry ball mills and wet ball mills for choice.

The Working Principle of Ball Mill:

This machine is a skeleton pattern ball mill with horizontal cylindrical turning gear, drive by outer gear and two hoppers. The material goes to the first hopper after the spiraling by the quill shaft from the feeding equipment. The hopper has ladder sheathing or corrugated sheathing with steel balls inside, which will fall under the effect of centrifugal force by the barrel and grind material. After the kibbling in the first hopper, by monolayer partition panel, the material will enter the second hopper, which has plane scale board with steel ball inside to grind material. The powder material will be discharged from the grid plate to finish the grinding.

|

Model |

Shell rotation speed |

Ball load |

Feeding size |

Discharging size |

Capacity |

Motor power |

Total weight |

|

Ф900×1800 |

36-38 |

1.5 |

≤20 |

0.075-0.89 |

0.65-2 |

18.5 |

5.85 |

|

Ф900×3000 |

36 |

2.7 |

≤20 |

0.075-0.89 |

1.1-3.5 |

twenty two |

6.98 |

|

Ф1200×2400 |

36 |

3 |

≤25 |

0.075-0.6 |

1.5-4.8 |

30 |

13.6 |

|

Ф1200×3000 |

36 |

3.5 |

≤25 |

0.074-0.4 |

1.6-5 |

37 |

14.3 |

|

Ф1200×4500 |

32.4 |

5 |

≤25 |

0.074-0.4 |

1.6-5.8 |

55 |

15.6 |

|

Ф1500×3000 |

29.7 |

7.5 |

≤25 |

0.074-0.4 |

2-5 |

75 |

19.5 |

|

Ф1500×4500 |

27 |

11 |

≤25 |

0.074-0.4 |

3-6 |

110 |

twenty two |

|

Ф1500×5700 |

28 |

12 |

≤25 |

0.074-0.4 |

3.5-6 |

130 |

25.8 |

|

Ф1830×3000 |

25.4 |

11 |

≤25 |

0.074-0.4 |

4-10 |

130 |

34.5 |

|

Ф1830×4500 |

25.4 |

15 |

≤25 |

0.074-0.4 |

4.5-12 |

155 |

38 |

|

Ф1830×6400 |

24.1 |

twenty one |

≤25 |

0.074-0.4 |

6.5-15 |

210 |

43 |

|

Ф1830×7000 |

24.1 |

twenty three |

≤25 |

0.074-0.4 |

7.5-17 |

245 |

43.8 |

|

Ф2100×3000 |

23.7 |

15 |

≤25 |

0.074-0.4 |

6.5-36 |

155 |

45 |

|

Ф2100×4500 |

23.7 |

twenty four |

≤25 |

0.074-0.4 |

8-43 |

245 |

56 |

|

Ф2100×7000 |

23.7 |

26 |

≤25 |

0.074-0.4 |

12-48 |

280 |

59.5 |

|

Ф2200×4500 |

21.5 |

27 |

≤25 |

0.074-0.4 |

9-45 |

280 |

54.5 |

|

Ф2200×6500 |

21.7 |

35 |

≤25 |

0.074-0.4 |

14-26 |

380 |

61 |

|

Ф2200×7000 |

21.7 |

35 |

≤25 |

0.074-0.4 |

15-28 |

380 |

62.5 |

|

Ф2200×7500 |

21.7 |

35 |

≤25 |

0.074-0.4 |

15-30 |

380 |

64.8 |

|

Ф2400×3000 |

twenty one |

twenty three |

≤25 |

0.074-0.4 |

7-50 |

245 |

58 |

|

Ф2400×4500 |

twenty one |

30 |

≤25 |

0.074-0.4 |

8.5-60 |

320 |

72 |

|

Ф2700×4000 |

20.7 |

40 |

≤25 |

0.074-0.4 |

22-80 |

380 |

95 |

|

Ф2700×4500 |

20.7 |

48 |

≤25 |

0.074-0.4 |

26-90 |

480 |

102 |

|

Ф3200×4500 |

18 |

65 |

≤25 |

0.074-0.4 |

As per process conditions |

630 |

149 |

|

Ф3600×4500 |

17 |

90 |

≤25 |

0.074-0.4 |

As per process conditions |

850 |

169 |

|

Ф3600×6000 |

17 |

110 |

≤25 |

0.074-0.4 |

As per process conditions |

1250 |

198 |

|

Ф3600×8500 |

18 |

131 |

≤25 |

0.074-0.4 |

45.8-256 |

1800 |

260 |

|

Ф4000×5000 |

16.9 |

121 |

≤25 |

0.074-0.4 |

45-208 |

1500 |

230 |

|

Ф4000×6000 |

16.9 |

146 |

≤25 |

0.074-0.4 |

65-248 |

1600 |

242 |

|

Ф4000×6700 |

16.9 |

149 |

≤25 |

0.074-0.4 |

75-252 |

1800 |

249 |

|

Ф 4500×6400 |

15.6 |

172 |

≤25 |

0.074-0.4 |

84-306 |

2000 |

280 |

|

Ф5030×6400 |

14.4 |

216 |

≤25 |

0.074-0.4 |

98-386 |

2500 |

320 |

|

Ф5030×8300 |

14.4 |

266 |

≤25 |

0.074-0.4 |

118-500 |

3300 |

403 |

|

Ф5500×8500</spa |

Personne à contacter : Zeng Ralap , 0773 6812095

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de Ball Mill Rechercher dans la catégorie : Biens d'équipement Rechercher dans la catégorie : ball, mill |

Samedi 23 août 2014

Quantité : 10 - Prix : 13,50 €

Technische Daten: - 100% brandneu zum Samsung Galaxy S3 i9300 - Rubustes und modernes Design - Schutz vor Kratzern, Stössen und Staub - Einfach zu montagen und reinigen - Mit doppel Fenster - Material: PU - Farbe: gelb Lieferumfang: - 1x Cover mit doppel Fenster in gelb f. Samsung...

365buy

- 3600 - Thun

- 07 62 07 63 81

Mardi 13 août 2013

Quantité : 12 - Prix : 85.68 €

Ensemble robe de bébé Le style ne bis-2021-1128 Du matériel: 100% coton Dimensions - 3/6, 6/12, 12/18 mois Couleurs - comme le montre Emballage - 12 pcs tailles assorties à €7.14 de chacun Pour plus d'informations et d'autres styles voir http://www.sheldonplc.fr/robes-bebe-hiver...

Sheldon International Ltd.

- Sheldon

- LE5 0HJ - Leicester

- +44 116 2761069

Lundi 06 mai 2013

Quantité : more than - Prix : 6-12 USD

Model number : DR 1343 Feature: peasant dress with cute mixing of many fabric types Material: A13.0 - White plain 100% cotton, A20.1 - Orange plain 65% cotton & 35% polyester, A18.0 - Yellow plain 65% cotton & 35% polyester, CR 4.0 - Orange chevron 100% cotton Supply type...

Babeeni Ltd.,Co

- 10000 - Ha Noi

- +841682842451

Paiement sécurisé