Aerated concrete panel production line

Aerated Concrete Panel Production Line(http://www.chinablockmachine.com/product/ps_4_31_1.html)

1). Technology Certification and Evaluation

Aerated concrete panel production line, based on cement, lime, silicon sand, etc as main raw materials ,according to the structure requirement, added different amount preservative treatment of steel fabric pieces ,is a light porous new type of green environmental protection building materials. By high temperature high pressure, steam curring reaction,producing cellular crystallized aerated concrete panel, its density is less than general cement-based materials, and has a good fire-resistant, fire prevention, sound insulation, heat insulation, heat preservation and incomparable performance.

Our aerated concrete panel production line comes with intellectual property rights. It has obtained the ISO9001 International Quality Management System Certificate and CE certificate. Also, our production line has been approved by BV and TUV.

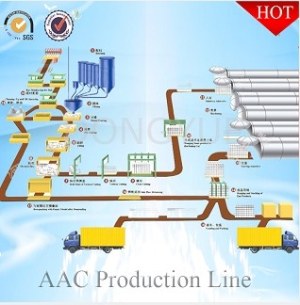

2). Aerated concrete panel production line Technical Process

1. Rebar Mesh Cage Preparation

Use the straightening machine to process the steel bar coil into the type with the required length. With the welder, the processed steel bar will be welded into the steel meshes. Later, the suspending welder makes those meshed into the wanted cages. Next, the rebar mesh cage will be painted, and then dried in the drying box. Finally, it will be conveyed to the assembly area.

2. Mesh Cage Assembly and Drill Rod Plugging

During the assembly process, the mesh cage will be installed on to the cabinet frame according to the size. And then it will be fixed with the drill rod.

After the installation, the poured horizontal molding box will be transported to the designated spot. The dill rod plugging crane puts the mesh cage cabinet into the mould. Later, the cabinet will be sent to the curing room. Until the green bricks have been cut, the cured molding box will be then delivered to the place where drill rod is plugged. Pull out the drill rods, and transport the molding box to the cutting place.

3. Batching, Pouring, Curing (Refer to the Autoclaved Aerated Concrete Block Production Line)

3). Application of Autoclaved Aerated Concrete Panel

ALC autoclaved aerated concrete panel can be divided in to the partition plate, external wall plate, roof panel, fire-proof board, etc. All those panels are mainly used for concrete or steel buildings.

a. ALC Internal Wall Panel

This internal wall panel is applicable for all kinds of buildings, for instance, hotels, schools, etc. On the wall panel, you can install the air conditioning, heater, and the like.

b. ALC External Wall Panel

This type of wall panel features excellent heat preservation, heat insulation performance. Therefore, it is thinner than general type autoclaved aerated concrete panel. This product can satisfy many countries' applications where heat insulation is required.

Personne à contacter : daisy xu, 865398036228

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de Aerated concrete panel production line Rechercher dans la catégorie : Biens d'équipement Rechercher dans la catégorie : aerated, panel, concrete, line, production |

Tuesday 23 January 2018

Quantité : 1000 tonne - Prix : 0.90€

Novation Recycling répond à vos besoins en vêtements d'hiver : la meilleure qualité, une livraison rapide, prix avantageux... Contactez-nous pour commander ! Novation Recycling est une entreprise de recyclage et de tri de vêtements fripes et autres produits (papiers, déchets d'équipement...)

Novation Recycling

- novation recycling

- 21310 - Mirebeau-sur-Bèze

- 03 80 65 14 65

Friday 17 September 2021

Prix : 100USD

The working principle of the early opk ovulation test is to determine whether a woman is pregnant by detecting the HCG value (the value of human chorionic gonadotropin). Although many early pregnancy test strips indicate that women can detect pregnancy after a day's delay in their...

Shecare-ikangtai

- 100084 - Haidian

- 86 010 56231097

Wednesday 24 April 2024

Prix : 10000-40000 RMB/MT

Stainless steel strip for sale is a narrow and elongated piece of stainless steel. stainless slit coil is commonly used as edging or trim on various products or as a component in mechanical and electrical applications due to its strength and durability. Normandy Metal, your reliable...

Normandy Metal Industry Co., Ltd.

- normandymetal

- 528000 - foshan

- 0757 8870 0589

Paiement sécurisé