Specifications

1,disposable paper plate machinery

2,speed 120-600 pcs/m

3,making 4-12 inch paper plate

4,easy operate and maintenance

RXM-L-1 disposable paper plate machinery

VIdeo: https://www.youtube.com/watch?v=FUlRF9yLHLo

1.Model RXM-L-1 Intelligent disposable paper plate machinery

2.RXM-L-1 Intelligent Highest-speed Paper Plate Forming Machine is designed for the market requirement, It has integrated the

pneumatic and the mechanic technologies, which makes it has the functions of faster working speed, higher

safety-performance, safer operation and easier maintenance .

3.Model RXM-L-1 Intelligent Highest-speed paper plate machine adopts high efficient pressurizing air cylinder, so that the Max.

pressure can reach to 25T ,Compared with the oil pressure cylinder, it has the advantages of high speed, environment

protection and humanism design .

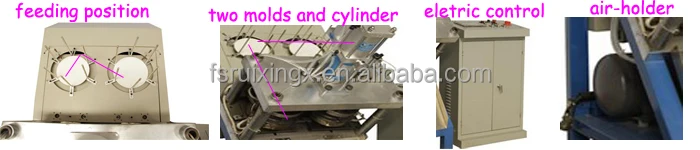

4.Standard RXM-L-1 Paper plate machine has two working stations , each station install one set of mold and each station has

separately PLC digital control and electric control.

5.It is widely applied to make paper plate (or aluminum foil laminated paper plate) in round (rectangle, square, circular, or irregular)

shape. Machine speed changes against the material (paper) thickness and the plate size.

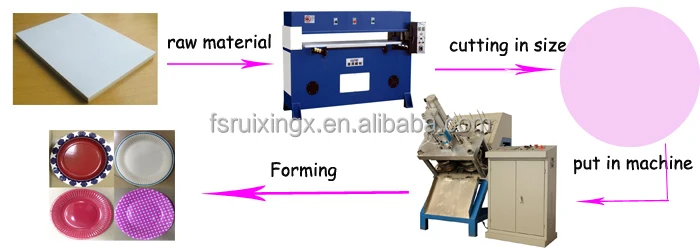

Production Line

RXM-L-1 Paper Plate Machine Technical Specification :

-

HS. Code: 8441309000

-

Paper Plate Size : 4--12 inch (mold exchangeable);

-

Raw Material : Paper/paperboard, Aluminum foil coated paper, One side PE coated paper or other;

-

Suitable paper weight : 40--600 gsm (gram a square meter);

-

Rated Productivity : 25--250 piece/minute (total two stations, about 1500-15000pcs per hour);

-

Total Power : 3 KW;

-

Power Source : 220V 50Hz or other required;

-

Total Weight : 600 Kg;

-

Package Size (L x W x H) : 1.6m x 1.6m x 1.7m ;

-

Air source : Working pressure 0.8Mpa, Air out-put 1.0 m3/minute (need to buy Air compressor);

-

If your plate is very large, and the paper is up 600gsm, we design a special machine for you.

Pressurizing Air Cylinder Technical Specification :

All the parts we use international brands

Japan Mutisu PLC and OMRON electric control;

AirTAC air treatment

Air flow vlume : 0.8 cubic/min;

Air pressure: 0.6-0.8Mpa;

Air cylinder stroke: 150mm;

FAQ

1. How can I get some samples?

1) We are honored to offer you samples. New clients are expected to pay for the courier c ost, the samples

are free for you.

2) Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT,

etc. to have the samples collected;

or inform us your DHL collection account.Then you can pay the freight direct to your local carrier company.

2. How does your factory do regarding quality control?

Quality is priority! Every worker keeps the QC from the very beginning to the very end:

1) All raw material we used are environmental-friendly;

2) Skillful workers care every detail in handing the stamping, printing, stitching, filling, packing process;

3) Quality control department specially responsible for quality checking in each process.

3. How about the sample lead time and production lead time?

Normally the sample lead time is 2 - 7 days and the production lead time is 10 - 25 days according to the order

quantity and requirement.

Localisation : NO.16,PO QU ROAD,SHA CHONG,LISHUI,NANHAI,FOSHAN,CHINA, 528244 LISHUI,

Personne à contacter : Albee Wong, +86 13690381870