|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Pro / B2B

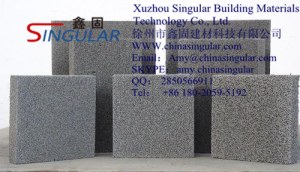

CHINA SINGULAR Composite Insulating Foam Cement Panel

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Item |

Unit |

Performance index |

Test method |

|

|

Type Ⅰ |

Type II |

|||

|

Dry density |

Kg/㎡ |

≤300 |

≤250 |

GB/T 5486 |

|

Heat conductivity coefficient |

W/(m•k) |

≤0.08 |

≤0.06 |

GB/T 10294 |

|

Compressive strength |

MPa |

≥0.50 |

≥0.40 |

GB/T 5486 |

|

Tensile strength |

MPa |

≥0.13 |

≥0.13 |

JGJ144 |

|

Water absorption (V/V) |

% |

≤10.0 |

≤10.0 |

Appendix A |

|

Drying shrinkage value |

mm/m |

≤0.80 |

≤0.80 |

GB/T11969 rapid method |

|

Carbonization coefficient |

- |

≥0.80 |

≥0.80 |

GB/T 11969 |

|

Softening coefficient |

- |

≥0.80 |

≥0.80 |

JGJ51 |

V. External heat insulation system construction of external wall:

|

Facing materials |

Heat insulation system structure |

Structure diagram |

||||||

|

①Base course |

②Interface layer |

③Leveling course |

④Tack coat |

⑤Heat insulation layer |

⑥Plastering coat |

⑦Facing layer |

|

|

|

Coating |

Concrete wall and various masonry wall |

Mortar interface (use required by the design) |

Waterproof mortar (use required by the design) |

Adhesive mortar |

Foaming cement panel |

Plastering mortar + net cloth + anchoring part |

Flexible water-resistant putty + coating |

|

VI. Precautions:

1. Before paving the panel, you should clear the surface dust.

2. The paving of the panel should start from the first floor, and the level line should pop up from the position 300mm away from the plinth ground from the bottom to top to pave it horizontally and transversely. The staggered joints between panels of upper and lower rows should be 1/2 the panel length.

3. The paste between the panel and the basic wall should be with no space left. An iron float should be used to coat every panel with a layer of over 3mm adhesive mortar evenly when pasting, and the pasting area should be more than 95%. You should paste and press the mortar to the base timely and to make sure that the gap of joint between panels should be no large than 1mm.

4. When composite foaming cement panel is in the corner of wall, you should pre-arrange the dimension and cut it to a proper size and vertically connect them in cross shape to ensure its perpendicularity with the corner.

5. When pasting the external corners around the window frame and the outer corners of wall, you should stretch out the vertical baseline to ensure the perpendicularity of the external corners. And the foaming cement panels to be pasted to the door and window edges should be cut into “L” shape and no split joint should be allowed. The gap between joints and window edges should be no less than 100mm.

Personne à contacter : Amy Lee, 0086 180 2059 5192

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de CHINA SINGULAR Composite Insulating Foam Cement Panel Rechercher dans la catégorie : Pro / B2B Rechercher dans la catégorie : foam, insulating, singular, panel, china, composite, cement |

Friday 31 December 2021

Quantité : 2000 sets/ - Prix : $100

Modern European style kitchen cabinets often display a simple, unadorned style, featuring flat surfaces, little or no hardware, and flush doors. Traditional kitchen design tends to incorporate natural materials for cabinets, countertops, floors and furniture. As a professional kitchen...

HOLIKE CREATIVE HOME Co.,Ltd

- 510665 - Tian

- 86 20 89311964

- No 18 Keyun Road, Tianhe distric

Thursday 14 September 2017

Quantité : 20 PCS - Prix : USD 888/PC

SCHNEIDERBMKC8030310 Contact person: Miss Veronica WhatsApp: 86 18106957056 Phone: 008618106957056 E-mail: veronica@nseauto.com Skype: 8618106957056 QQ: 2206305349 Wechat: nseauto006 N.S.E.Automation is a leading global industrial supplier in China, specializing in automation...

N.S.E Automation Co.,Ltd

- 361006 - Xiamen Fujian

- 8618106957056

Friday 15 May 2020

Quantité : 4.000.000 - Prix : 0,26 €

PRODUITS AVEC TOUT LES CERTIFICAT EUROPEEN Les masques faciaux sont non tissés Résistance aux fluides modérée: 120 mmHg Barre de nez adaptable Ajustement parfait Acheteurs en gros, merci de bien vouloir diriger pour le prix. produit disponible en france par minimum de commande 50000 pcs : ...

LIMPID HEALTHCARE

- 69009 - LYON

- 06 12 90 21 08

- +33 6 12 90 21 08