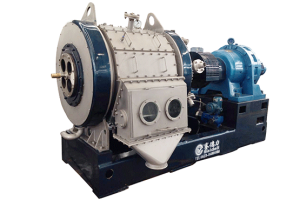

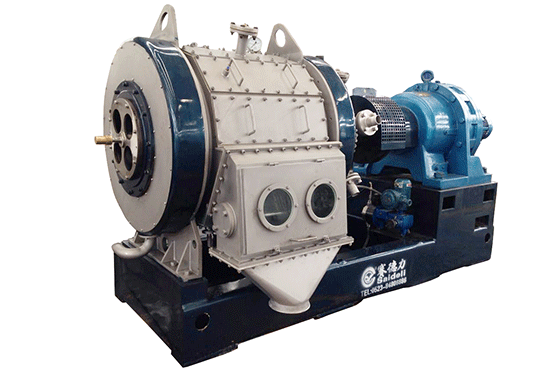

SAIDELI-INDUSTRIAL CENTRIFUGE SEPARATOR MACHINE MANUFACTURER

Jiangsu Saideli, an industrial centrifuge machine manufacturer, continuously develops high-tech and top-quality products which include industrial centrifuge separators, industrial centrifugal dryer, and industrial filter. As a national high-tech enterprise, Saideli integrates scientific research, sales, and manufacture of centrifugal separation machine, centrifugal separation equipment as well as some dryers and filters. With its powerful ability, well-known reputation, strict quality management, and top service system, Saideli is famous for centrifuge separation equipment, becoming a leading brand in China and the centrifuge separator machine has been exported all over the world.

SAIDELI CENTRIFUGE SEPARATOR FOR SALE

Saideli integrates scientific research, sales, and manufacture of centrifuges as well as some dryers and filters. The main products are the industrial centrifuge, industrial centrifugal Dryer, and industrial filter.

Industrial Centrifuge Manufacturer

Horizontal Centrifuge

Vertical Centrifuge

Top Suspended Centrfuge

Industrial Centrifuge FAQs

Industrial Centrifuge

GKH Series automatic siphon centrifuge is a piece of solid liquid separation machine that adopts continuous operation and intermittent discharging. The industrial centrifuge is controlled by PLC and regulates the speed by frequency convertor, braking system applies dynamic braking and regenerative braking, the whole separation process is an automatic circular process and the manual operation mode is applicable to be changed over from automatic operation mode. GKH Series automatic siphon centrifuge is more suitable for separating such products as small solid-phase granularity and which is hard to be separated. The industrial centrifugal separator solid liquid is widely used in the pharmaceutical, chemical, and foodstuff industries.

Industrial Centrifugal Dryer

FSD Centrifugal Dryer

This machine integrates separating, drying and sterilization with perfect seal system, absolute security, which is particularly suitable for high potency compounds, pharmaceutical output stages, highly toxic products, application methods, agents that have to be manufactured in sterile environment and products sensitive to oxygen.

Industrial Filter

Continuous Rotary Drum Pressure Filter

Nutsche Filter

Industrial Centrifugal Filter FAQs

Nutsche multiple function filtering washing and drying facility (three in one) can finish a series of processes such as stirring, reaction, filtering, washing, dehydration and drying(repulsing can also be processed) etc. With its simple structure and simplified working process, it has a higher efficiency, easier exchanging of product and good performance of automation without any cross-contamination. Meanwhile, cleaning plant building and basic investing fee can be reduced. It can be widely applied in the industries such as pharmacy chemical industry, food, printing dyeing industry. So it is especially suitable for the occasion where demands a high cleanliness or short runs but multiple types of product and large quantities of product. It is in accordance with both GMP Norm and FDA Norm.

HOW TO CHOOSE

THE RIGHT CENTRIFUGAL SEPARATION MACHINE?

01.

First

If you have production capacity for suspension separation and centrifugal separation equipment which can be sold on the market, the industrial centrifuge separator will be your suitable choice. The centrifuge separator includes all kinds of centrifuges, which are widely used in all areas. As one of the best centrifugal separator manufacturers in China, Saideli has many different types of centrifuge separator for sale. As long as you need suspension separation, you can find a suitable centrifugal separation machine here.

02.

Second

If your centrifugal separators are with high additional value and request high clean production environment, centrifugal dryer will be suitable with compact and whole seal structure which integrates separation and drying in one machine.

03.

Three

If your centrifuge separator machine are sticky and not able to be separated by normal method, an industrial filter with pressure filtration and low rotate speed will be helpful.

APPLIED TO WHAT

CENTRIFUGAL SEPARATOR USES

- 01-

Pharmaceutical Products

During the production of API products, there will be a separation between solid products and solvents, solid liquid separation equipment will be suitable for the separation as well as dehydration and products can be washed inside during the production process. The design of solid liquid separation centrifuge can meet GMP and FDA requests, such as application of centrifugation in pharmacy. Also, the mother liquid after separation and washing liquid can be collected separately.

- 02-

Chemical & Farm Chemical

For production and chemical and farm chemical products, a centrifuge is used for the separation of solid and liquid of the suspension from the reactor after the reaction. With good seal performance, the harmful chemical products will not contact the operator and also the toxic gas will not enter into the air. Meanwhile, with an ex-proof design, the chemical centrifuge will be suitable for production in hazardous areas.

- 03-

New Energy

During recycling of waste battery, there will request extraction of nickel, cobalt, manganese, lithium and copper etc from the waste battery so as to recycle and reuse. A centrifuge is widely used recently in this industry.

- 04-

Food

For the food industry, a centrifuge is mainly used for the production of starch and sugar, especially tapioca starch and wheat starch, glucose and sweetener.

TIPS TO IMPROVE THE CENTRIFUGE SEPARATION EFFICIENCY

Right centrifuge separator model will improve separation efficiency and increase production capacity as well as reduce labor cost and energy consumption.

Right model choice, speed choice, filter bag size and program set will improve the separation efficiency of the centrifuge separation equipment.

Meanwhile, the right clean gap time of the filter bag can reduce residual filter cake and improve the filtration efficiency of the bag so as to shorten separation time. Also the more stable the flow rate into the centrifugal separation machine, the higher the separation efficiency.

INDUSTRIAL CENTRIFUGAL SEPARATION EQUIPMENT FAQS

Q

What Are the Applications of Centrifuges?

A

Centrifuges are used for industrial and medical applications. Industrial centrifuges separate solids from liquids, liquid-liquid separation, and liquid-liquid-solid separation Filtering centrifuges us...

Q

What Is the Rule of Centrifuge?

A

The centrifuge works in terms of the principle of sedimentation, where the centrifugal acceleration causes denser substances and particles to move outward in the radial direction. The centrifugal acce...

Q

What Is the Use Of Centrifugal Separator?

A

Centrifuge is used for solid and liquid separation of suspension with suitable solid concentration.

Q

What Are The Different Types Of Centrifuge?

A

By discharging method, centrifuges can be separated into horizontal centrifuge machine and vertical centrifuge machine. By operating mode, the centrifugal separator can be separated to batch centrifuge and continuous centrifuge. Meanwhile, size of centrifugal separation machine can be separated into lab and industrial use. Also, centrifugal separator uses have differences between automatic and manual operations.

Q

How Big Is An Industrial Centrifuge Separator?

A

Usually industrial centrifuge with diameter 800 mm, 1000 mm, 1250 mm, 1600 mm, and the biggest is 1800 mm. Detail size choice will be done per your throughput capacity.

Q

Are Solid Liquid Separator Machines Safe To Operate?

A

Our centrifuge separation equipment is ex-proof design with good seal performance, so it is very safe to be used in hazardous area with flammable and explosive solvent.

Q

What Is The Centrifugal Separator Working Principle?

A

Solid liquid separation equipment can separate solid and liquid in the suspension under centrifugal force formed by high-speed rotation of the drum, and solid will be left inside the basket and liquid will be drained out through the outlet. Then solid will be collected by the scraper.

Localisation : NO 31, ZHONGZHOU ROAD, JINGJIANG CITY, 214500 Jiangsu,

Personne à contacter : centrifuge saideli, 0086 523 84808886