At Richconn, we rely on rack and suspend technology to provide black oxide coating services that are delivered quickly and meet high quality standards. Our customers receive parts with a striking black finish without the performance issues that can be associated with traditional painted surfaces.

Based on years of experience, Peregrine is focused on meeting the exact specifications and industry standards for black oxide coating services for your parts.

Need help with black oxide coating or other plating needs? Please feel free to contact us!

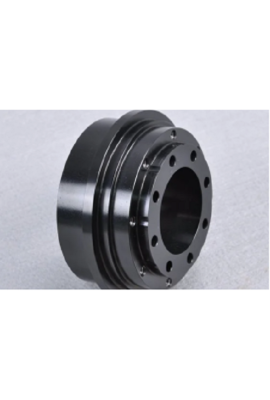

Black Oxide Coating - Your Protective Coating for Metal Parts

For a striking black finish and superior corrosion protection, black oxide coating may be the best choice. There is no need to worry about paint flaking, coating loss or surface abrasion. All of these properties make black oxide finish an economical and reliable solution for ensuring that your metal parts have an attractive appearance.

What Types of Parts Can be Black Oxide Coating Services?

Black oxide coatings are commonly applied to a wide variety of metal parts, especially those requiring corrosion protection and a black appearance, such as: bolts and nuts, steel and fittings, automotive parts, weapons and firearms parts, agricultural equipment parts, machine parts, tools and blades.

Types of Black Oxide Coatings Service We Can Offer You

Richconn's black oxide coating service started in 2008, with 16 years of metal blackening coating experience, we can provide you with black oxide coating services on iron, aluminum, copper, nickel, stainless steel, and steel for increasing the corrosion resistance of your parts, minimizing light reflection, and enhancing the appearance of your parts. It can be used with oil or wax coatings for maximum corrosion resistance.

Why Choose Richconn as Your Black Oxide Blackening Coating Company

16 Years of Black Oxide Coating Processing Experience

16 years of experience in providing professional black oxide coating processing services to over 1000 mold factories.

Daily production capacity of more than 12,800 pieces

We have more than 80 sets of advanced black oxide processing equipment.

Senior engineers customized surface treatment program.

Can provide you with a variety of metal materials surface treatment process solutions.

4.24*7 hours response, waiting around the clock.

Equipped with professional and technical personnel, all-weather to help you solve the problem of product use

How Do You Blacken Metal?

The process flow of metal blackening is as follows:

·

Degreasing: Boil the parts in degreasing solution for 20~30 minutes at 80~100 ℃.

·

Cold water cleaning: rinse with flowing clean water.

·

Pickling: wash with hydrochloric acid solution at room temperature for no more than 30 seconds.

·

Blackening (put the blackening liquid in a stainless-steel container and heat the bottom with an electric furnace)

·

Water washing: wash with flowing cold water or warm water for 30-60 seconds.

·

Boiling water cleaning: 2-5 minutes.

·

Saponification treatment: temperature 80~90°, time 2-3 minutes.

·

Immerse in oil: immerse in transformer oil or spindle oil at about 80° for 1-3 minutes, and then the finished product is cleaned.

As a professional cnc machining exporter, Richconn provides precision machining parts, blackening coating, precision cnc machining, etc. Want to know more about blackening surface treatment, contact us.

Localisation : 1212, Zehua building, intersection of Longhua Meilong road and donghuanyi Road, Songhe community, Longhua street, Longhua District, Shenzhen,GuangDong,China, 518110 shenzhen,

Personne à contacter : .com richconncnc, 086 0755 28025755