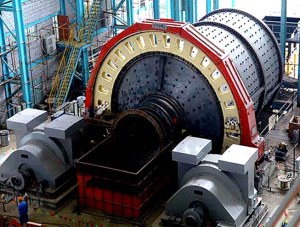

Wet ball mill is a kind of energy-saving industrial grinding mill which adopts rolling bearings and has high efficiency. Wet grid mining ball mill processing capacity can reach 160 tons per hour. It usually grinds coarser ores.

Instruction of Wet Ball Mill

The operating environment of the wet grate ball mill is to treat the pulp with high water content, and the pulp concentration is between 30% and 50%. Wet ball mill is arranged at the end of the ore row grid, ball grinding machine can be forced to row ore, so wet grid type ball mill in a variety of open or closed circuit occasions, ball mill mining is used for coarse-grained mineral grinding; wet ball mill can also be used for one stage grinding or one of two stages grinding. Because the lattice type is forced ore discharge, so the grinding time of material in the shell is relatively short and the discharge particle size is relatively coarse, which is generally 0.2-0.3mm, it suitable for the primary grinding stage. Compared with overflow ball mill, wet ball mill can better avoid the problem of over-grinding.

Structure of Wet Ball Mill

The working principle of wet ball mill is to make it rotate slowly through the transmission device, and the material is fed into the feeding end of the shell. The material in the shell is crushed due to the drop impact and self-grinding of the steel ball and the ore itself. As the material is constantly fed, the pressure makes the material in the shell move from the feeding end to the discharging end. The material reaching the finished product size is discharged from the discharging end. When wet grinding, the material is taken out by the current; In dry grinding, the material is taken out by air flow. There is the grate in the discharging end of ball mill, the ball mill discharge ore by the grid plate, pulp surface in the shell is low, reduce the ore over grinding, and prevent the discharge of the steel ball.

Advantage of Wet Ball Mill

Wet ball mill adopts large double-row self-aligning roller bearings, which is easy to start while reducing friction and can save about 20%-30% energy.

Wet ball mill adopts wavy ball mill liner replacement, which enlarge the contact surface of the ball ore, effectively strengthens the grinding effect, it has a lifting effect on the ore, and reduces the consumption.

With a large ore discharging end, the production capacity is effectively improved and increased.

For ball mills with smaller diameters, the integral frame can be used, which is more convenient in construction and heavy equipment machinery installation.

Lubricating devices can ensure the size of gear lubrication is reliable.

Method of Adding Steel Ball to Wet Ball Mill

Adding steel ball is a more complex problem, customers must pay attention to the following two situations in the operation of ball mill:

1. When the processing material granularity is larger or hardness is higher, the proportion of large balls become small, and the grinding products will run rough, which cannot meet the requirements of fineness. Moreover, the processing capacity is also limited, affecting the grinding efficiency.

2. When processing materials with small ore size and low ore hardness, the phenomenon of coarse product strength will also appear if the ratio of small balls is less. The pellets should be properly added to increase the proportion of pellets and to adapt to the nature of the treated ore, so as to obtain better product fineness. Therefore, the ball loading system of the mine ball mill must be loaded strictly in proportion to prevent the imbalance of proportion.

Spare Parts and Services of Wet Ball Mill

All spare parts can be customized according to practical use or needs, aiming to improve the mechanical property. CIC technical team uses the most stringent standards and tolerances to ensure the safety and reliability of equipment. With over 60 years of equipment manufacturing experience, each product can achieve higher cost efficiency, increase output or capacity, reduce maintenance and downtime, improve safety and minimize environmental impact.

Provide Professional and Comprehensive Services of Wet Grid Ball Mill

CIC can prepare all the spare parts for customers all along, ranging from the shell to the lubricating oil pump and filter. All machine parts can be shipped at any time to guarantee the shortest delivery time.

Machine maintenance

Appropriate maintenance will help to extend the service life of the wet ball mill to ensure the sustainable operation of your equipment.

Grinding mill inspection

During the operation of the industrial ball mill, the sudden shutdowns, higher maintenance costs, and losses in production will be occurred if you fail to discover problems in time.

CIC could provide customers with detailed and standardized inspection to make you find problems as quickly as possible. For instance, you should keep the trunnion bushing clean and a mechanical adjustment in the best position to improve the integrity and efficiency of the rolling mill.

Shutdown planning and optimization

Downtime equal to the loss of money, and we know that every minute of our clients is precious. So a set of services we developed to help you plan, execute and optimize equipment downtime. We can help you achieve efficient, safe, and timely shutdown through tool management to machine running and to time and motion analysis.

Repair services

The grinding mill will age and the production efficiency and reliability will decrease with long-term grinding work. However, a proper repair can ease the aging problems to ensure your production purpose. CIC can provide customers with a full range of repair services from partial to a complete renovation.There are many girth gear manufacturers, but we are one of the best choices for you.

Localisation : 99 Hengshan Road, Jianxi District, Luoyang, Henan, China, 471000 luoyang,

Personne à contacter : mech cice, 0379 64088445