Pro / B2B

Copper Wire Granulator Cable Recycling Machine Copper Plastic Separation Machine

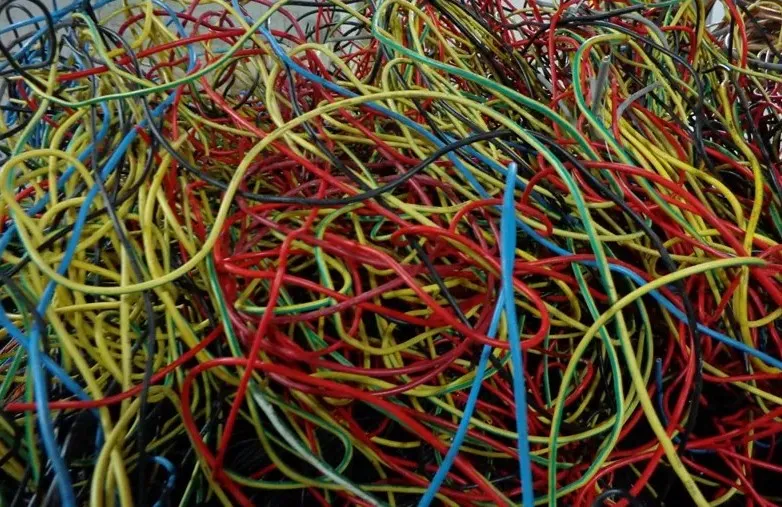

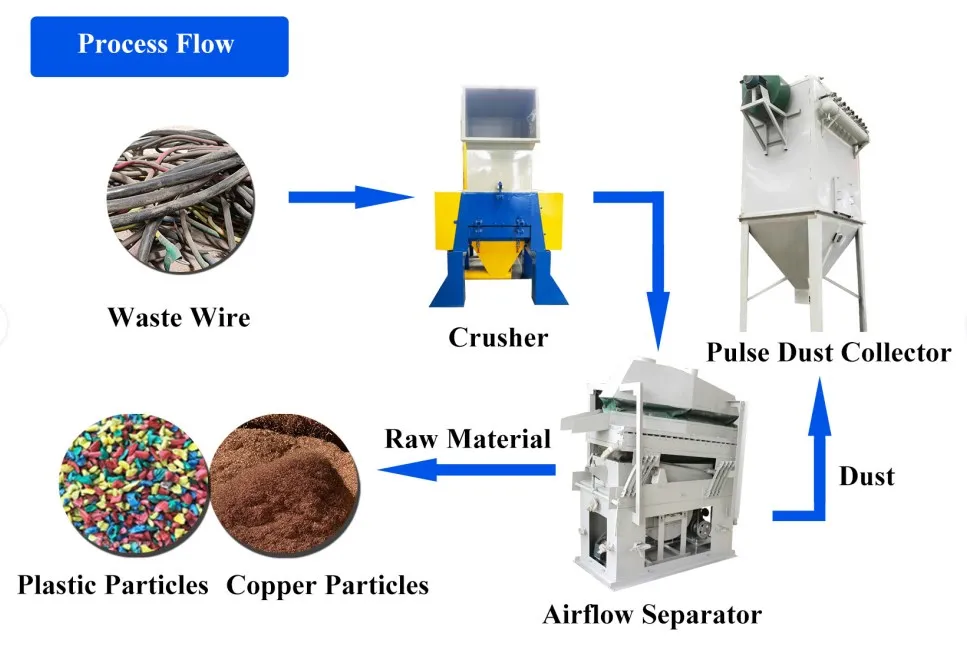

It is a production line for recycling waste copper wires and cables to obtain copper particles and plastic particles. It is mainly used to recycle various waste cables, separate raw materials into fine copper meters and PVC, and apply to wire diameters ranging from 0.3 mm to 20 mm, such as automobile wires, car bottom wires, motorcycle wires, computer wires and communication wires, etc.

Process waste wire and cable into copper and plastic pellets. Copper and plastic are separated, and the separation efficiency can reach 99%. Copper pellets can be sold directly or further refined. Copper can be refined into cathode copper with a purity of over 99.99%. Plastic particles are generally PVC or rubber materials, and can also be sold directly.

Raw Material: automobile wires, car bottom wires, motorcycle wires, computer wires and communication wires, etc.

Final Products: Copper Powder And Plastic Powder

First, a shredder is used to shred the material, which is about 3cm long, and then the material is further shredded by a knife pulverizer to peel off plastic and copper. The pulverized materials enter the high-precision airflow sorting machine through the wind conveying system for sorting to obtain plastic and copper. The unsorted plastics enter the electrostatic sorting machine for secondary sorting to ensure the reuse rate of copper. At the same time, pulse dust collection equipment is used to effectively control dust overflow, and the dust removal efficiency is as high as 99% to ensure that there is no dust pollution in the production process.

|

Model

|

Capacity(KG/H)

|

Power(kw)

|

Size(mm)

|

Weight(KG)

|

|

YT-TMJ-200

|

100-200

|

30

|

2400*1800*2800

|

2390

|

|

YT-TMJ-500

|

300-500

|

53

|

6000*6000*4600

|

4790

|

|

YT-TMJ-1000

|

800-1000

|

154

|

20000*12000*4600

|

12000

|

1. Compact structure, beautiful appearance, reasonable layout and convenient installation.

2. Using PLC control, the equipment is uniformly fed, intelligent operation, automatic alarm function, easy to operate, and the equipment runs stably.

3. The shredder adopts a high-hardness main shaft, which makes the shredder more impactful when carrying objects. The tearing type is adopted, which is composed of a micro cutter head and a cylindrical cutter shank, which greatly reduces the investment of wearing parts.

4. The grinding machine, sorting equipment and dust collecting equipment are combined with a platform, which makes the equipment easy to move and transport, and increases the flexibility of the equipment.

5. The rotor of the grinding machine adopts alternate cutter shafts, which makes the grinding machine have higher production efficiency, lower noise and more stable operation.

6. This equipment adopts the combination of airflow sorting equipment and high-voltage electrostatic equipment, so that the sorting rate can reach more than 99%. 7. The bag dust collection equipment effectively controls dust overflow, and the dust removal efficiency is as high as 99%, which meets the requirements of the national Hamburg "Comprehensive Emission Standard of Air Pollutants" GB16297-1996, without secondary pollution. 8. The blade and screen of the wearing parts are made of special wear-resistant and high-toughness alloy material, which improves the service life and reduces the production cost. 9.The recycling system re-shreds the raw material to ensure the complete separation of copper and plastic.

Raw Material: automobile wires, car bottom wires, motorcycle wires, computer wires and communication wires, etc.

Final Products: Copper Powder And Plastic Powder

First, a shredder is used to shred the material, which is about 3cm long, and then the material is further shredded by a knife pulverizer to peel off plastic and copper. The pulverized materials enter the high-precision airflow sorting machine through the wind conveying system for sorting to obtain plastic and copper. The unsorted plastics enter the electrostatic sorting machine for secondary sorting to ensure the reuse rate of copper. At the same time, pulse dust collection equipment is used to effectively control dust overflow, and the dust removal efficiency is as high as 99% to ensure that there is no dust pollution in the production process.

|

Model

|

Capacity(KG/H)

|

Power(kw)

|

Size(mm)

|

Weight(KG)

|

|

YT-TMJ-200

|

100-200

|

30

|

2400*1800*2800

|

2390

|

|

YT-TMJ-500

|

300-500

|

53

|

6000*6000*4600

|

4790

|

|

YT-TMJ-1000

|

800-1000

|

154

|

20000*12000*4600

|

12000

|

1. Compact structure, beautiful appearance, reasonable layout and convenient installation.

2. Using PLC control, the equipment is uniformly fed, intelligent operation, automatic alarm function, easy to operate, and the equipment runs stably.

3. The shredder adopts a high-hardness main shaft, which makes the shredder more impactful when carrying objects. The tearing type is adopted, which is composed of a micro cutter head and a cylindrical cutter shank, which greatly reduces the investment of wearing parts.

4. The grinding machine, sorting equipment and dust collecting equipment are combined with a platform, which makes the equipment easy to move and transport, and increases the flexibility of the equipment.

5. The rotor of the grinding machine adopts alternate cutter shafts, which makes the grinding machine have higher production efficiency, lower noise and more stable operation.

6. This equipment adopts the combination of airflow sorting equipment and high-voltage electrostatic equipment, so that the sorting rate can reach more than 99%. 7. The bag dust collection equipment effectively controls dust overflow, and the dust removal efficiency is as high as 99%, which meets the requirements of the national Hamburg "Comprehensive Emission Standard of Air Pollutants" GB16297-1996, without secondary pollution. 8. The blade and screen of the wearing parts are made of special wear-resistant and high-toughness alloy material, which improves the service life and reduces the production cost. 9.The recycling system re-shreds the raw material to ensure the complete separation of copper and plastic.

Localisation : Zhengzhou West Industrial Zone, 451200 ZHENGZHOU,

Personne à contacter : CUI SHENG, 86 18530843555

Bonne affaire : acheter au vendeur

Consultez notre guide pour effectuer une transaction en toute sécurité ! En aucun cas Algomtl ne peut être tenu responsable des annonces publiées. Seule la responsabilité du vendeur ou de l'acheteur en cas de litige est engagée. Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

Mercredi 18 décembre 2024

Quantité : 500 - Prix : USD0.5/pc

American Pinch clamps Factory in China The Supplier of one of Fortune top 500 Machine, Technology, Quality from USA SAE Type SEC Stainless Steel Single Ear Pinch Clamps KSL7123 Beverage, automotive, marine, motorcycle and industrial pinch clamps. The patented 300 Series Stainless...

- 233010 - Bengbu

- 86 552 4193229

Dimanche 02 décembre 2012

Quantité : 1 - Prix : 95 000,00 €

Vends camion sonde foreuse Ingersoll Rand T4W année 1978 avec 215 m de tubes en acier 2 marteaux sd6 et sd8 + 3 taillants et tout l'outillage nécessaire. Camion et Sonde/Compresseur entièrement remis à neuf, pompes et circuit hydraulique ainsi que pompe à mousse inclus, Factures...

- 13100 - Bouznika

- 00 212 678052146

Mardi 08 mars 2016

Quantité : 100~500

Bubble Bath Spa Massager MSW-104 Bubble Bath Spa Massager is a new generation of home spa massager and is optimized for use in bath with the quality of tranquility, relaxing and luxury life. Configuration of MSW-104 is One-Touch Control Panel with Minimal and fashionable design...

- 414 - Taichung City

- +886 4 23367128

|