Flex circuit PCB is a type of printed circuit board with a flexible base material, allowing the board to bend and fold. This type of circuit board is becoming increasingly popular in a variety of applications, and is being used in the development of everything from medical devices to consumer electronics.

At the forefront of this technology is the Golden Triangle Group, a leader in the flex PCB industry for over 10 years. As an experienced flex pcb company in the world, Golden Triangle Group has the expertise and knowledge to provide high-quality, cost-effective flex circuit PCB solutions. From rapid prototyping and fabrication to full-scale production, the Golden Triangle Group has the experience and resources to meet any flex PCBs requirements.

With a commitment to quality and customer satisfaction, the Golden Triangle Group has become a trusted and reliable printed circuit board company for flex PCB products and services. With a comprehensive selection of flex board PCB materials, custom flex PCB designs, and superior manufacturing capabilities, the Golden Triangle Group is the go-to source for any China flexible circuit board needs. Whether you need a single board for a prototype or large-scale production, the Golden Triangle Group will work with you to design and manufacture the perfect flex board PCB for your application.

Flex PCB Material

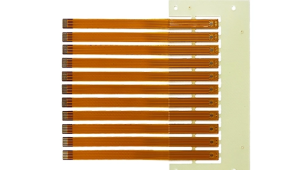

Flexible Printed Circuit Boards (flex PCBs) are a revolutionary technology in the electronics industry due to their ability to bend and shape with ease. Flex circuit PCBs are an advanced form of printed circuit boards (PCBs) that are made of flexible materials such as polyimide, polyester, and other flexible substrates. These materials are much more pliable than traditional PCBs, allowing them to be bent and shaped into any form. This makes them perfect for applications where traditional PCBs wouldn't fit or wouldn't function properly.

China flex PCBs are found in a variety of different applications, including medical devices, consumer electronics, automotive, and aerospace. Thanks to their flexibility and durability, they are in high demand in these industries. Flex PCB circuit boards allow devices to be designed in new and innovative ways while being able to withstand the rigors of a given environment.

The flex printed circuit material is also important in determining the quality of the circuit board. The material chosen must be able to withstand the high temperatures and chemical exposure of the application. It must also be able to provide a reliable connection between components. Quality flexible circuit board china materials are durable and reliable, providing effective operation for many years.

Flexible circuit board China technology has advanced significantly over the years, allowing circuit boards to be more reliable and cost-effective. Today, flexible circuit PCBs are often used in place of traditional rigid PCB board, due to their superior flexibility and lower cost. With the advent of new materials and technologies, flexible printed circuit boards can now be used in applications where traditional PCBs could not be used.

Flex PCBs are an ideal technology for a wide range of applications, due to their flexibility, durability, and cost-effectiveness. If you are looking for a reliable and cost-effective solution for your application, then our flex PCBs are an excellent choice. With the right flex PCB material, you can ensure that your circuit board works reliably and efficiently.

Flex Printed Circuit Board Technology

Flex Printed Circuit Board technology used in our PCB manufacturing company is quickly becoming an essential component of the modern electronics industry. Flex PCBs, also known as flexible Printed Circuit Boards, are a type of printed circuit board (PCB) that uses flexible base materials instead of the traditional rigid board materials. They use a thin and lightweight material that can be bent and folded, allowing them to be used in a variety of applications where traditional rigid boards cannot. Flex circuit boards offer a range of benefits such as increased design flexibility, greater space-saving ability, and enhanced durability.

Flexible Printed Circuit Boards are made up of multiple layers of materials, including a base layer of flexible dielectric material, copper traces, and various cover layers that protect the copper traces from damage and corrosion. Flexible Printed Circuit Boards are used in a variety of industries from automotive to telecom applications. Automotive manufacturers use custom flex PCBs to reduce the number of wires and connections in their vehicles, allowing for a more energy-efficient and space-saving design. Telecom companies also use custom flexible PCBs in their equipment, allowing for more reliable and efficient connections with fewer components.

Flexible circuit PCBs offer a range of advantages over traditional rigid Printed Circuit Boards. They are much more flexible, allowing for more design flexibility, and they are much more lightweight, making them easier to install and transport. They are also much more durable, as they can withstand a greater range of temperatures and environmental conditions. This makes them ideal for use in a variety of industries, particularly those with harsh environmental conditions.

Flexible printed circuit board china technology is rapidly evolving, offering more and more advantages to manufacturers and consumers alike. If you're looking for a reliable and efficient Printed Circuit Board solution, then Flex PCBs made by our professional flex circuit manufacturer are the way to go.

Localisation : Room 401,No.5 Building, Dingfeng Technology Park, Shayi Community, Shajing Town, Bao'an District,Shenzhen,Guangdong Province,China, 518125 Shajing Town,

Personne à contacter : gtpcba gtpcba, 86 0755 85275761