|

|

|

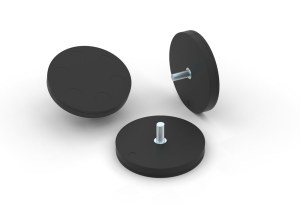

Pro / B2B

NdFeB Rubber Coated Magnet with Threaded Stud

|

|

Cette page concerne les importateurs et exportateurs de NdFeB Rubber Coated Magnet with Threaded Stud Rechercher dans la catégorie : Pro / B2B Rechercher dans la catégorie : coated, magnet, rubber, threaded, with, ndfeb, stud |

Dimanche 15 décembre 2024

réfrigérateurs americain Samsung

Quantité : 1000 - Prix : 590,00 €

Offre exceptionnelle : Lot de 1000 réfrigérateurs américains Samsung RS68CG882ES9 à prix déstockage ! Saisissez cette opportunité unique avec un lot de 1000 réfrigérateurs américains Samsung RS 68 CG 88 2E S9 à un prix de déstockage exceptionnel de 590 €/unité par 500 unités. Ce modèle haut de gamme est parfait pour les grossistes cherchant à proposer à leurs clients un produit combinant design élégant, technologie avancée, et performance énergétique. Caractéristiques principales...

TRANSIDI

- 22440 - PLOUFRAGAN

- 02 30 96 63 26

- 33(0)603670505

Vendredi 06 décembre 2024

Quantité : Customers - Prix : Negotiable

Repoussoirs et nettoyeurs sont conçus pour repousser les cuticules à l'écart des ongles et nettoyer la surface de l'ongle sans rayer ou endommager la cuticle.There sont diverses cuticules et nettoyants pour les ongles et les orteils. Cuticules avec fin courbé sont faciles à utiliser...

Aerona Beauty manufacturers of beauty care instruments

- aeronabeauty

- 51310 - Sialkot

- 923217106500

Jeudi 12 décembre 2024

Automatic Gear Pump Liquid Filling Machine FG-465 is designed and engineered to produce outstanding quality and precision filling suitable for various products like shampoo, hot sauce, lubricant oil etc. FG-465 can also replace piston or peristaltic module for the flexibility of filling demands...

Autopack Co.,Ltd

- autopacker

- 33454 - Taoyuan City

- +88 6 33 68 98 06