|

|

|

Divers

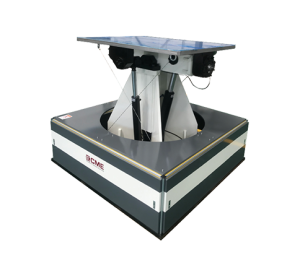

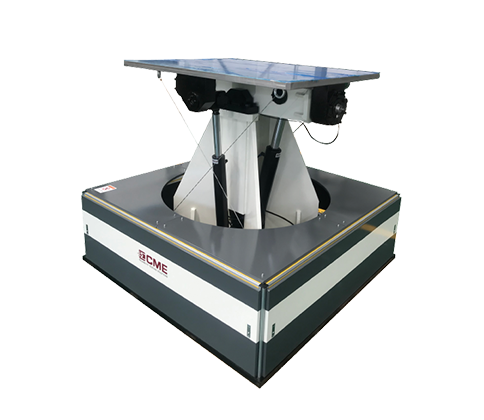

WHAT IS MULTI-AXIAL SIMULATION TABLE? |

|

Cette page concerne les importateurs et exportateurs de WHAT IS MULTI-AXIAL SIMULATION TABLE? Rechercher dans la catégorie : Divers Rechercher dans la catégorie : table, what, simulation, axial, multi |

Mardi 04 juin 2013

VOTRE COURRIER POSTAL SUR INTERNET (BACKOFFICE) www.ubidoca.com Vous voyagez très souvent ? Vous travaillez beaucoup à l'étranger ? Vous avez plusieurs domiciles ? Nous fournissons la solution la plus efficace pour gérer vos affaires et votre courrier postal à distance sur Internet. Nos services - Mise de votre courrier postal sur Internet dès réception par notre équipe. - Vous pouvez le consulter 24h/24, o...

UBIDOCA SARL

- courrier

- 01220 - Divonne les Bains

- 04 50 20 49 70

- 06 18 63 06 53

Jeudi 11 février 2016

Prix : 1999$ A DEBATTRE

LOT DECORATIONS DE NOEL A VENDRE 6MBO -Ensemble de 6 minis boules dorees sur tige Quantite: 54 6MBR -Ensemble de 6 minis boules rouges sur tige Quantite: 66 6MBV -Ensemble de 6 minis boules vertes sur tige Quantite: 52 BBA -Tige de petit fruits noirs et argents de 19" Quantite...

S&P Le Magasin Des Commercants

- H2G 2W6 - MONTREAL, QC

- +15 1 42 74 55 47

Mardi 11 mars 2025

Quantité : 418 - Prix : 5,00 €

Tous nos articles sont neufs et étiquetés Nous vous proposons un lot de linge de maison comprenant nappes, sacs à pain, tablier, serviette de table brodé main, etc... Différents modèles et coloris Quantité 418 pièces divisible Prix 5 euros la pièce Lot visible dans nos locaux...

a la bonne eur'o rabais

- labandetiange

- 29290 - milizac

- 06 79 59 55 01

- 06/79/59/5/01