|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Pro / B2B

NUTSCHE FILTER

|

|

Standard Model |

UNFCD |

UNFCD |

UNFCD |

UNFCD |

UNFCD |

UNFCD |

UNFCD |

UNFCD |

|

Norminal Filtering Area (m2) |

0.38 |

0.5 |

0.63 |

1.1 |

2 |

3.14 |

3.8 |

5.3 |

|

Inner diamater (mm) |

700 |

800 |

900 |

1200 |

1600 |

2000 |

2200 |

2600 |

|

Norminal Volume (m3) |

0.25 |

0.4 |

0.5 |

1.13 |

2 |

3.14 |

3.8 |

5.3 |

|

Bucket Height (mm) |

690 |

800 |

1000 |

1000 |

1000 |

1000 |

1000 |

1000 |

|

Filtering Cake Thickness (mm) |

200 |

200 |

300 |

400 |

400 |

400 |

400 |

400 |

Nutsche FILTER Industrial, fixed filtering washing drying machine

|

Standard Model |

UNFCD |

UNFCD |

UNFCD |

UNFCD |

UNFCD |

UNFCD |

UNFCD |

UNFCD |

UNFCD |

UNFCD |

UNFCD |

|

Norminal Filtering Area (m2) |

0.63 |

1.1 |

2 |

3.14 |

3.8 |

4.52 |

5.3 |

6.15 |

7 |

8 |

10 |

|

Inner diamater (mm) |

900 |

1200 |

1600 |

2000 |

2200 |

2400 |

2600 |

2800 |

3000 |

3200 |

3600 |

|

Norminal Volume (m3) |

0.5 |

1.13 |

2 |

3.14 |

3.8 |

4.52 |

5.3 |

6.15 |

7 |

8 |

10 |

|

Bucket Height (mm) |

800 |

1000 |

1000 |

1000 |

1000 |

1000 |

1000 |

1000 |

1000 |

1000 |

1000 |

|

Filtering Cake Thickness (mm) |

300 |

400 |

400 |

400 |

400 |

400 |

400 |

400 |

450 |

450 |

450 |

NUTSCHE FILTER WORKING PRINCIPLE

The multifunctional filter is made up of a round tank with a welded head and a liftable chassis. There is mechanical sealing on the head and agitator with the knife. The process is as follows:

Step one: filter

Agitator at the bottom and start rotating. At the same time, feed suspension into the filter. Under the agitating, solid will not sediment so quickly in the suspension. After lots of filter liquid has been drained, lift the agitator to make the filter more effective.

Step two: press filter or vacuum filter

Move the agitate shaft to the highest point and stop agitating. Operate press filter or vacuum filter(note: feed pressure from the top of the tank during vacuum filter for keeping positive pressure inside the tank.)

Step three: squeeze

Along with the reduction of the filtered liquid, the surface of the filter cake will be broken. Start the agitator and rotate in the opposite direction. Make sure the agitator is higher than the surface of the cake. Move down during rotation to squeeze material into smaller pieces so as to drain the filtered liquid.

Step four: wash

After the formation of the filter cake, make it into suspension by adding washing liquid to make material and washing liquid contact thoroughly. And operate filtration again until form filter cake again. For better quality filter cake or for less filter liquid in the filter cake, washing can be done more than one time.

Step five: discharge

Before discharge, open the vent valve to release the inner pressure and lose the ejector of the discharge device. Rotate the agitator in the same direction as the filter cake discharge direction and slowly scraper the material for discharge.

Nutsche Filter Highlights

01.

Hermetical system: nutsche filtration is a hermetical system which can avoid pollution to air from solvent, meanwhile agitated nutsche filter reduces the danger of worker's poisoning because of contact with toxic materials.

02.

Complete recycling: nutsche filter dryer material and solvent get nearly complete recycled, thus, it is of great economic value, especially when material and solvent is expensive.

03.

Drying process is at the same time: filter and drying process are finished in the same container. Container wall is selective to be equipped with heating cover to enable heating operation.

04.

Continuous operation: pressure nutsche filter enables filtering and drying in the continuous container with no necessity of processing wet filtering cake. This kind of centrifugal separation equipment can be connected under the filter where wet filtering cake may be discharged directly. The dry product can be conveyed to weight or package etc. processes.

05.

Human labor saving: non-technician can finish such operation after simple training. No necessity for technician in the process such as on and off of machine, automatic feeding and discharging.

06.

Full cleaning effect: filtering cake can get thoroughly cleaned because nutsche filtration has automatically spraying and repulping. What's more, the nutsche filter has lower demand for washing liquid quantity. So pollution quantity and processing fee of wasted water can both be reduced.

07.

Cleaning manufacturing: equipped with dust collector, all agitated nutsche filter dryer sizes can collect at the dust after drying which can meet the demand for cleaning manufacturing.

There are many industrial centrifuge manufacturers, but we are one of the best choices for you.

Personne à contacter : centrifuge saideli, 0086 523 84808886

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de NUTSCHE FILTER Rechercher dans la catégorie : Pro / B2B Rechercher dans la catégorie : nutsche, filter |

Jeudi 26 juin 2025

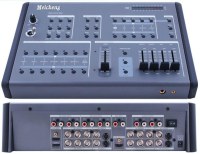

Applications : CMX-12 is a high definition digital AV Mixer, which is a simple type of HD/SD Video Mixer Editor to switch and effects. Each input BUS supports 6 inputs (2 x HDMI, 2 x Component, 2 x S-Video and Composite video) and also Background Color for special effect. The output...

Meicheng Audio Video Co., Ltd.

- meicheng

- 23511 - New Taipei City

- 886 2 82280311

Vendredi 15 décembre 2017

online katalogOEM PART NO DESCRİPİTİON 66072 Crown Wheel and Pinion FOR CARRARO 13X30 66941 Crown Wheel and Pinion 15x37 2277448 CATERPİLLAR AİR FİLTER OUTER 2277449 CATERPİLLAR AİR FİLTER İNNER 01/117901 FAN BELT 01/124403 FAN BELT 01/124404 02/100073 Oil Filter Canister Type, MEDİUM...

ANAC MAKINA CO LTD STI

- 34800 - İSTANBUL

- +905069691531

- +9005069691531

Lundi 25 mai 2015

- Product Description - ~Catalog 1. What is a large space? 2. The importance and complexity of large space monitoring. 3. Large space monitoring term introduction 1 - "pixel density" - requirement for clarity 4. Large space monitoring term introduction 2 - "invalid pixels" -...

Shenzhen RuiHan Technology CO., Ltd

- amy dai

- 518000 - Shenzhen City (深圳市)

- +86 0755 27901878

- +86 18718772818