|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Pro / B2B

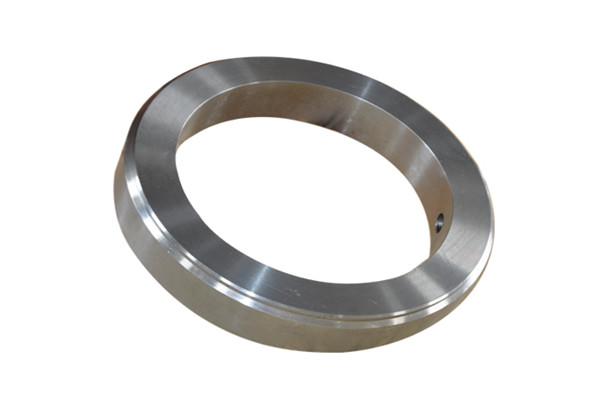

CNC Grinding

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Machinery |

5 |

|

|

Material |

Alloys Steel |

Bronze Alloys |

|

Copper |

Stainless Steel |

|

|

Brass |

Carbon Steel |

|

|

Ceramics |

Glass |

|

|

Features |

Roughness |

High Precision Tolerance |

|

Mirror Polishing |

|

|

|

|

|

|

|

|

|

|

|

Maximum Dimensions |

Surface Grinder3000mm*550mm/Internal and external grinderφ1500mm*5000mm |

|

|

Milling Tolerance |

±0.001mm |

|

|

Inspection Capabilities |

CMM |

Projector |

|

Imaging Measuring Instrument |

Hardness |

|

|

Metallographic Microscope |

Non-destructive Equipment |

|

|

Automatic Thread Inspection Equipment |

|

|

|

Surface Finished |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Thread |

UNF |

UNC |

|

NPT |

SAE |

|

|

Metric |

BSPP |

|

|

BSPT |

JIS |

|

|

DIN |

G |

|

|

R |

ZG |

|

|

Certification |

ISO9001-2008 |

ISO/TS16949 |

Advantage of CNC Grinding

Precision

The high precision of our precision surface grinding services is the embodiment of CNC grinding machine quality, it directly reflects on the production quality of machining parts. Due to the high precision requirement of CNC grinder, it is required to optimize the structure of the machine tool, adopt high-grade functional components, and have good static, dynamic, and thermal performance.

Composite

Multi-axis linkage control and multi-process compound grinding are some of the main technical characteristics of a CNC grinder. CNC grinding machine can realize the grinding of complex surface and composite cutting tools at one time.

High Speed

CNC grinding serbices machine processing form is mainly high-speed, high-precision form grinding. The application of CNC diamond grinding tools and CBN grinding tools and other superhard material grinding tools puts forward new requirements for the high-speed performance of grinding machines, such as the grinding wheel shaft generally adopts the motorized spindle with the speed of more than 10000 R / min; the CNC grinding machine tool is required to have excellent electromechanical coupling, servo optimization and high acceleration performance. The application of direct drive components such as motorized spindle, torque motor and the linear motor has become a new highlight of the high-speed performance of CNC grinder.

ETCN is a professional cnc company, we provide machining and manufacturing services, vacuum pressure casting, fabrication and machining and etc. Want to know more? contact us.

Personne à contacter : etcn etcn, 021 61493577

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de CNC Grinding Rechercher dans la catégorie : Pro / B2B Rechercher dans la catégorie : grinding |

Mardi 14 juillet 2015

Quantité : 15000MT - Prix : 2500euro

Haute Qualité Fil de cuivre Scrap 99,99% Milberry Nous sommes des fournisseurs de haute qualité fil de cuivre Scrap 99,99% Milberry spécification Fil de cuivre SCRAP, (Millberry) 99,78% à une pureté de 99,78% min. 99,78% max. CUIVRE: 99, 9% CARBONE: 0,03% COBLET: <0, 001...

CA PRODUCTS CO, LTD

- 10110 - bangkok

- +66 2 62 61 74 11

- +66 9 62 91 74 69

Samedi 28 juin 2014

Lien Fa Injection Machinery Co., Ltd. was established in 1967, specializing in the design and manufacture of plastic machines such as Injection Molding Machine, Direct Hydraulic Clamping Injection Molding Machine, Saving Energy Injection Molding Machine, High Speed High Pressure...

S&J

- 407 - Taichung , Taiwan

- 886437038989

Mardi 10 juillet 2007

Quantité : 2000 Tons

we sell diferents grains of high cuality : Quinoa, Cañahua ,Amaranth, Maca and his derivates like pops, flakes, fluor.Localisation : Urbanizacion"Los Pinos" Zona Norte, none Oruro, Personne à contacter : Jean-marie Galliath, +59 1 25 28 51 88

SONAPTO S.R.L.

- sonapto

- none - Oruro

- +59 1 25 28 51 88

- +59 1 70 42 43 19