|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Pro / B2B

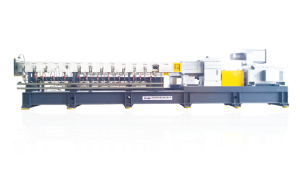

Plastic Compounding Machine

|

|

Item |

Description |

|

Place of origin |

China |

|

Brand name |

JWELL |

|

Model number |

CJWH-85 |

|

Capacity |

300-500kg/hr |

|

Typical application |

TPU |

|

Packaging details |

Wooden pallet packing |

|

Delivery time |

90days |

|

Payment terms |

TT. LC |

Specifications of Plastic Compounding Machine

|

Model |

Diameter |

L/D |

Screw speed |

Motor Power |

Torque per shaft |

Specific torque |

Capacity Range |

|

mm |

rpm/min |

KW |

N.m |

T/A3 |

kg/hr |

||

|

CJWH35 |

35.6 |

24~68 |

600 |

30 |

235 |

8.7 |

75~150 |

|

1000 |

45 |

8.7 |

110~220 |

||||

|

CJWH40 |

41.1 |

24~68 |

600 |

45 |

357 |

8.7 |

110~220 |

|

1000 |

75 |

8.7 |

190~380 |

||||

|

CJWH52 |

51.4 |

24~68 |

600 |

90 |

692 |

8.7 |

220~440 |

|

900 |

132 |

8.7 |

330~660 |

||||

|

CJWH65 |

62.4 |

24~68 |

600 |

160 |

1224 |

8.7 |

400~800 |

|

900 |

220 |

8.7 |

550~1100 |

||||

|

CJWH75 |

71 |

24~68 |

600 |

220 |

1880 |

8.7 |

550~1100 |

|

800 |

315 |

8.7 |

800~1600 |

||||

|

CJWH85 |

81 |

24~68 |

600 |

315 |

2713 |

8.7 |

800~1600 |

|

800 |

450 |

8.7 |

1100~2200 |

||||

|

CJWH95 |

93 |

24~68 |

600 |

500 |

4131 |

8.7 |

1250~2500 |

|

700 |

600 |

8.7 |

1500~3000 |

||||

|

CJWH110 |

108 |

24~68 |

500 |

630 |

6346 |

8.7 |

1500~3000 |

|

600 |

800 |

8.7 |

2000~4000 |

||||

|

CJWH120 |

120 |

24~68 |

500 |

900 |

8705 |

8.7 |

2250~4500 |

|

600 |

1000 |

8.7 |

2500~5000 |

||||

|

CJWH135 |

132 |

24~68 |

400 |

900 |

11586 |

8.7 |

2250~4500 |

|

500 |

1000 |

8.7 |

3000~6000 |

Plastic Compounding Machine Application

Petrochemical Powder Pelletizing and Powder Compouding:

Petrochemical powder pelletization and powder modification are one of the most important applications for twin screw extrusion machine. Through continuous efforts, optimization, and improvement, the integration of industry resources has been widely recognized by the market.

Bio-degradable Plastic Compouding and Pelletizing Series:

Typical application as plastic alloy, starch filled compound, bio-mass filled compound or mineral power filled compound for bio degradable plastics as PLA, PBAT, PBS, PPC, PCL, TPS, and PHA, etc.

Plastic compounder machine Performance and Advantages

The screw and barrel adopt the "building block" structure, which has good interchangeability, and can be used in any combination according to the different material processing technology;

The cylinder body is made of nitrided steel and bimetal materials, which are wear-resistant and corrosion-resistant, and extend the service life; the threaded elements are made of nitrided steel and high-speed steel. Normal tooth surface clearance, and good self-cleaning;

The specially designed connection method and transmission device enhance the strength of the threaded element and the mandrel. The above measures achieve the purpose of uniform material dispersion, good mixing and plasticizing effect, short material retention time, and high conveying efficiency.

JWELL Extrusion Machinery Co. Ltd is a high-tech manufacturer specializing in the research and development of yarn spinning machines, we provide polyester yarn making machine, jwell extruder, plastic profile extrusion, compounding machine. Contact us to know more.

Personne à contacter : Sun Mac, 86 0519 87878918

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de Plastic Compounding Machine Rechercher dans la catégorie : Pro / B2B Rechercher dans la catégorie : machine, compounding, plastic |

Tuesday 09 December 2025

Quantité : 10.000 - Prix : 1500 a 1600$mt

We are able to supply the best quality frozen food products worldwide. Our prices are very competitive and are the best you can find. We spend our time in understanding our customers need and we have the skills and ability to meet every customer's specific requirement. With a skill...

IRAN Trade

- ogfrance

- 93201 - Tehran

- +33 7 62 58 79 19

Friday 21 November 2014

Quantité : 1 UNIT - Prix : 1,5 USD

Nous avons été la fabrication de rouleaux à peinture depuis 10 ans dans nos usines à Konya et d'Istanbul. Nos rouleaux de peinture sont classées en trois types selon l'application que tout peut être utilisé pour les deux peintures à base d'eau et de solvants des peintures à base...

TURKON EXPORT LTD.

- 42050 - KONYA

- +905353265862

Tuesday 09 December 2025

Quantité : 80000 Ream - Prix : $0.79/Ream for 8000

CARACTÉRISTIQUES - Dimensions de la feuille: 210mm x 297mm / 297mm x 420mm normes International Paper Taille (ISO) A4 / A3 - Qualité: importé 100% pâte de bois vierge - Blancheur: 102-104%, blanc naturel - Classement: A - Epaisseur: 106cm - Capacité: copie à grande vitesse de 100 ppm...

NATH LAOH LTD

- 50100 - Chiang Mai

- +66 9 95 35 59 56