Graphite rod is made of carbon, graphite, and appropriate adhesive. It is formed by extrusion. Graphite composite rod has high-temperature resistance, good conductivity and is not easy to break. It is suitable for cutting the metal into a satisfactory shape. The electric heater commonly used in high-temperature vacuum furnaces is easy to oxidize at high temperatures. Except for the carbon graphite rods for vacuum furnace, high density graphite rod can only be used in a neutral atmosphere or reducing atmosphere. Its thermal expansion coefficient is small, thermal conductivity is large, high-temperature resistance, extreme cold, and extreme heat resistance are good, the price is cheaper.

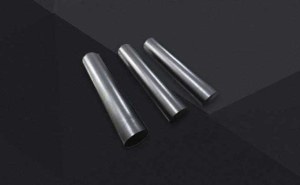

Graphite Rods for Sale

High Temperature Resistant Graphite Rod

High temperature resistant graphite rod for furnace is a cylindrical material of artificial graphite, which can achieve mechanical load-bearing, high-temperature resistant medium material, and so on. The high-quality characteristic of graphite rod is the characteristic of graphite, which has the advantages of low resistivity, high-temperature resistance, high-pressure resistance, and so on.

Oxidation Resistant Graphite Rod

It is used for purifying oil, medicinal casing, purifying organic coolant of the atomic reactor, and adsorbing radioactive waste;

Graphite Degassing Rod

Using graphite degassing rods can prolong the service life of the rotor, save degassing costs, reduce the number of rotor replacements, and more importantly, improve degassing quality.

Advantages of graphite rod compared with impregnated graphite

A graphite rod is made by mixing carbon graphite powder and various adhesives in a certain proportion, and then pre molding, pressing (hot extrusion or cold forming), or high-temperature heat-treatment process. This method can be used to produce , plates, , gate valves, pumps, etc. it can also be used as metal composites, couplings, mechanical equipment sealing rings, cylinder engine pistons, etc. compared with impregnated graphite, it has the following characteristics

1. The production and manufacturing mode is relatively simple. Raw materials can use crushed graphite to produce carbon graphite products and control the cost;

2. The porosity is small, the sorting structure is symmetrical, and the water permeability is good.

3. After forming, the appearance is high density and bright, and there is no need to process except the connecting end.

4. The heat transfer coefficient is less than that of impregnated graphite, and the coefficient of thermal expansion is very large.

Excellent organic chemical reliability, heat transfer, conductivity, temperature resistance, heat resistance, and high impact toughness;

The reason why the price of graphite rod is different

Graphite rod is a non-metallic cylindrical product and one of the crystalline minerals of carbon. It has the advantages of high thermal conductivity, conductivity, high-temperature resistance, and durability. After the pyrolytic graphite rod is heated in the air, it forms a dense silicon oxide film on the surface to form an antioxidant maintenance film, which has the effect of extending its service life. Why are the prices of graphite sticks different?

1. Original information

Raw materials include packaging cost, labor cost, transportation cost, and consumption cost.

2. Specifications

The price of graphite carbon rods is related to the specification. Generally, the larger the size, the higher the price.

3. Craft

The more complicated the consumption process of each graphite carbon rod, the price will also be affected.

Application field of graphite rod

Graphite rod is a kind of non-metallic product, which is formed by extrusion of carbon, graphite, and appropriate adhesive. It is not easy to break and is high-temperature resistant. You can see it everywhere. What's its use?

1. Used in the chemical industry

In order to ensure the safety of chemical products in the manufacturing process, a graphite carbon rod can isolate the flame. Because it produces volume under heated conditions, and then expands sharply, resulting in suffocation flame.

2. High-temperature metallurgy

In order to save more metal, we usually use graphite rods as the mold of glassware, which is conducive to making the casting size more accurate.

3. Wear-resistant and smooth

Generally, it can be used as a piston cup to transport corrosive media.

In the machinery industry, if only smooth oil is used, the product can not achieve good results in high speed, high temperature, and other conditions. By using a graphite carbon rod, we can make it slide rapidly at relatively high temperatures.

4. Used for fire resistance

We use graphite rod in steelmaking, called protective agent, which is the lining of metallurgy.

Localisation : Yingda road west, Xiaotun Village, Jinhe, Huixian City, Henan Province, 453600 Huixian,

Personne à contacter : tai Zhong, 0373 6812218