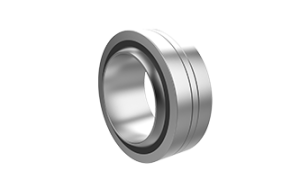

The spherical plain bearing is a kind of spherical sliding bearing. Its sliding contact surface is an inner spherical surface and an outer spherical surface. It can rotate and swing at any angle during the movement. It is made of various special processing methods such as surface phosphating, frying(stress fracture opening), padding, spraying, etc. The spherical plain bearing has the characteristics of large load capacity, impact resistance, corrosion resistance, wear resistance, self-aligning and good lubrication. As one of the most professional plain bearings suppliers in China, THE Bearings offers you four types of plain bearings as following.

Plain Bearing Definition

Sliding bearing is a bearing that works under sliding friction. Sliding bearings work smoothly, reliably and without noise. Under liquid lubrication conditions, the sliding surfaces are separated by lubricating oil without direct contact, which can greatly reduce friction loss and surface wear, and the oil film also has a certain vibration-absorbing ability, but the starting friction resistance is large. The part of the shaft supported by the bearing is called the journal, and the part that matches the journal is called the bearing bush. In order to improve the friction properties of the bearing surface, the layer of anti-friction material cast on its inner surface is called a bearing lining. The materials of the bearing shell and bearing bush are collectively referred to as sliding bearing materials. Sliding bearing is generally applied in high-speed and light-load conditions.

The Application of Spherical Plain Bearing

Spherical plain bearings are widely used in engineering hydraulic cylinders, forging machine tools, engineering machinery, automation equipment, automotive shock absorbers, water conservancy machinery and other industries. The spherical plain bearing is a spherical sliding bearing, and the basic type is composed of inner and outer rings with spherical sliding spherical contact surfaces. Depending on its structure and type, it can bear radial load, axial load, or combined radial and axial loads at the same time.

Operating temperature:

The allowable working temperature of the spherical plain bearing is mainly determined by the matching materials between the bearing sliding surfaces, especially the plastic sliding surface of the self-lubricating spherical plain bearing, its load-carrying capacity will decrease at high temperature. For example, when the sliding surface material of lubricated spherical plain bearing is steel/steel, the allowable working temperature depends on the allowable working temperature of the lubricant. But for all lubricated and self-lubricating spherical plain bearings, they can be used in the temperature range of -30℃~+80℃, and maintain the correct bearing capacity.

THB is a professional bearing manufacturing company, we provide spherical plain, plain bearing housing, plain shaft bearing with housing, plain ball bearing, plain sleeve bearing, journal sleeve bearing and etc. Want to know more, contact us.

Localisation : 205,Building 9,No.589,Quwu Road,Minhang District,Shanghai,China, 200241 Shanghai,

Personne à contacter : Zhu Helen, 021 54846072