|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Véhicule

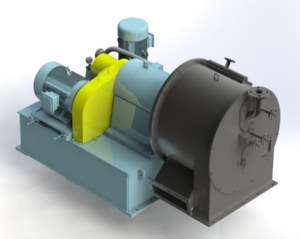

HR PISTONS PUSHING CENTRIFUGE

|

|

Item/Model |

HR400-N |

HR500-N |

HR630-N |

HR800-N |

HR1000-N |

|

Drum diameter (mm) inner/outer basket |

337/400 |

410/500 |

560/630 |

720/800 |

920/1000 |

|

Length of filtering (mm) |

160/160 |

180/180 |

240/240 |

300/300 |

240/320 |

|

inner/outer basket |

|||||

|

Speed (r/min) |

1500-2200 |

1200-2000 |

1000/1800 |

800-1600 |

650-1250 |

|

inner/outer basket |

|||||

|

Separating factor (N) |

503-1083 |

402-1118 |

352-1140 |

286-1145 |

236-875 |

|

inner/outer basket |

|||||

|

Length stroke (mm) |

40 |

50 |

50 |

50 |

50 |

|

Frequency of stroke (mm) |

30-80 |

50-70 |

30-80 |

30-80 |

20-70 |

|

Main motor power (KW) |

11 |

30-45 |

37-55 |

55-75 |

75-90 |

|

Oil pump motor Power(KW) |

5.5 |

22 |

30 |

45 |

45 |

Production capacity (t/h) 1-8 5-15 8-25 15-40 18-50

Overall dimensions L×W×H (mm) 2460×1286 3590×1430 3500×1760 3700×1800 4200×1900

×1030 ×1642 ×1265 ×1450 ×1900

Weight (Kg) 2480 3500 4000 6000 12000

Pusher Centrifuge Working Principle

HR series centrifuge is a kind of horizontal two-stage pistons pushing centrifuge and filtering centrifuge with continuous operation. Materials are fed continuously through feeding pipe and distributed evenly on the inner drum wall under the full involving speed of both inner and outer drum. Under the centrifugal force, liquid will be drained outside through the filtering net and the filtering holes on the drum wall while the solid will be intercepted in the inner drum and form a cake ring. While the drums of the two grades are revolving together at a same speed, the inner drum will move reciprocately continuously in axial direction under the driven of the pistons,then the pushing plate will be able to push out the filter cake from the inner drum. In the next step, the filter cake will be pushed into the outer drum for further separation. Then the outer edge of the inner drum will push the new filter cake to the out of the outer drum continuously and then discharged through the scraping groove.

PUSHER CENTRIFUGE MACHINE FEATURES

All operations under full speed;Automatic operation with continuous discharging and great capacity. Crystal shape will be kept completely;Filter cake can be washed inside the machine; Product contact parts adopt stainless steel with good anti-corrosion property.

PUSHER CENTRIFUGE MACHINE APPLICATION

Two stage pistons pushing centrifuge usually used for separating even suspension with medium and coarse particles(>0.1mm) and high concentration(>30%). The bigger the particle, the higher the solid content, the higher the capacity and the better the separating effect.

Our company started to manufacture HR pistons pusher centrifuge pdf since year 1965 with all models and more than 7000 sets output which has been widely used in chemical, fertilizer, salt, pharmacy and environment protection area.

HR Using Scope

This pusher centrifuge type is well used to separate suspension with its solid size is over 0.1mm and density is over 30%. The pusher centrifuge machine can be used in the chemical, light, pharmacy and food industry to produce sodium chloride ammonium fluoride ammonium bicarbonate, sodium sulphate, urea, caffeine, polyethylene, polystyrene, oxalate, nitrate.

The choice of HR pistons pushing centrifuge:

1. If the customer has high requirements on moisture content of filter cake, washing effect, and working capacity.

2. The density of the suspension should be within 30%-80% (weight percentage); ten even product particle size is over 0.1mm and its viscosity should be less than 10-1pa.s. You can choose HR pistons pusher centrifuge machine above conditions.

HR Pistons Pushing Centrifuge Highlights

01.

The pusher centrifuge machine can be operated continuously and steadily, which capacity is great.

02.

Because of its high separating factor, types of pusher centrifuge can be dehydrated fully in the two drums. So the filter cake will contain less moist.

03.

While there is a high demand to the purity of the products, the centrifuge can wash them and drain out the washing liquid and the mother liquid separately.

04.

Low and even consumption of the power among the pusher centrifuge .

As a pusher centrifuge manufacturer, we can also provide types of centrifuge separator for sale, anything you need, please contact us.

Personne à contacter : centrifuge saideli, 0086 523 84808886

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de HR PISTONS PUSHING CENTRIFUGE Rechercher dans la catégorie : Véhicule Rechercher dans la catégorie : pushing, pistons, centrifuge |

Vendredi 06 février 2015

Quantité : 100MT/Mont

Chemical Name: L-2-Amino-3-hydroxybutyric acid; Structure Formula: Molecular Formula: C4H9NO3 Molecular Weight: 119.12 Cas No: [72-19-5] Characteristics: White crystalline powder Quality Standards: USP24, FCCIV, AJI97 and etc. Item Specification USP24 FCCIV...

Zhaocounty Granray Bioproducts Co.,Ltd

- 051530 - NanBaiShe

- 8631180826581

Mercredi 20 novembre 2024

">Miel ">Polyflora miel, miel d'acacia, Miel de colza ">Spécification ">Humidité: <18% </span> ">Saccharose: <5% </span> 65% ">Réduire le sucre: > 65% ">Le fructose / sucre réducteur 48% ou 50% ">Couleur: blanc de l'eau, blanc...

ETS TAH INTERNATIONAL

- 00237 - Yaounde

- +237679759946

Mardi 12 juillet 2016

- - Product Description The P-50A sewer camera boasts the most dependable push rod inspection camera system from China,featuring 700TVL pan/tilt camera head,a robust cable reel,a state-of-heart-art LCD monitor,camera centering brackets and optional sonde and locators for...

Shenzhen Schroder Co.,LTD

- 518000 - 3th F, 9# Building, Tongfuyu Industrial Town, Xili Town

- +86 18664907847

- +8618664907847