Flat Rolling

The sheet leveller of BOYA is not only rooted in the basic theory of material elastic-plastic deformation but also closely follows the world's cutting-edge

technology. BOYA not only emphasizes learning from others but also insists on independent innovation. After years of specialized research, major breakthroughs have been made in high strength steelscale breakertension leveler, cold-rolled sheet high-speedtension leveler, high precision aluminum alloy tension metal leveler and multi-roll levelers in down steam finishing lines.

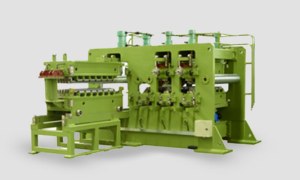

Since 2005, BOYA has provided more than 700 sets of leveler series products for many customers at home and abroad. Sheet leveller machine (dry/wet), multi-roll leveler machine, 23-roll precision levelers, pulling-straightening multi-roll combined leveler machine, leveler machine, etc., are veritable China's first brand of metal leveler machine. According to the structural characteristics, Boya's cold-rolled strip levelers can be divided into several types such as stretch-bending levelers, multi-roll levelers, and combined levelers.

Types of Sheet Leveler Machine

Tension Leveler Unit

Tension leveler machine applies tension to strip when bending by the rolls of smaller diameter, so as to make the strip produce elastic-plastic extension, and realize straightening.

Precision Leveler

Multi roll leveler straightens the strip by repeatedly bending it through alternating and rotating rollers.

Combined Type Tension Leveler

The combined leveler machine can straighten the strip through the joint action of stretching and bending tension leveler and multi-roll leveler. It is suitable for higher strength and thinner thickness material.

What is Metal Leveler Machine?

The so-called straightening machine sheet leveler machine is simply equipment for straightening metal profiles, bars, , wires, etc. The working principle of this kind ofmetal forming machineis to change the straightness of bars etc. through the straightening rollers. Generally speaking, the leveler machine has two rows of straightening rollers, of course there are exceptions. The two-roll leveler machine usually straightens materials of different diameters by relying on the angle change of the two rolls. leveler machines can be divided into pressure leveler machines, balanced roll leveler machines, shoe roll leveler machines, rotary reverse bending leveler machines and so on.

Straightening Process of Sheet Leveler Machine

When the sheet leveler machine is working, the position of its rollers is at a certain angle with the direction of movement of the product to be straightened. Two or three large ones are active pressure rollers, which are driven by the motor to rotate in the same direction. Several small rollers on the other side are The driven pressure rollers are rotated by the friction of the rotating rod or tube. In order to achieve the required compression of the product by the rollers, these small rollers can be adjusted forward or backward at the same time or respectively. Generally, the more the number of rollers, the higher the accuracy of the product after straightening by sheet leveller. After the product is bitten by the roller, it continuously moves in a straight line or rotates, so that the product undergoes various deformations such as compression,bending, and flattening, and finally achieves the purpose of straightening.

If you want to know more about coil processing lines, please visit our website.

Localisation : NO.3 Tianlai Road, Auto Industrial Park, Hi-Tech Zone, Xiangyang, Hubei, China, 441004 Hi-Tech,

Personne à contacter : chinery boyama, 0710 3273725