Protect the true love, committed to delicacy. As a professional pet treat manufacturer, Ranova is the first choice for your pets. Ranova freeze dried private label pet food and pet snacks are produced with fresh raw materials from high-quality farms, through advanced vacuum freeze-drying technology, in strict accordance with the standards for human food. Ten years of freeze-drying craftsmanship, to preserve the nutrition and taste of natural fresh meat, to retrace the original eating experience, and activate the natural instincts of pets as a predator.

Types of private label freeze dried dog treats

FREEZE DRIED PET FOOD

The production process of high quality pet food for sale/wholesale adopts a low-temperature mode, without any heating or defrosting, and always maintains the original flavor of fresh meat, as well as the appearance and shape of raw materials, and has good water rehydration, is natural and healthy pet food at a low price.

FREEZE DRIED PET TREAT

Vacuum freeze-drying processing of healthy pet treat is at extremely low temperature and high vacuum degree under the condition of dry processing, effectively maintain the fresh food color, aroma, taste and shape, and the maximum hold and suffer from indigestion materials of all sorts of vitamins, carbohydrates, protein and other nutrients and chlorophyll, enzymes, amino acids, and other nutrients and flavor substances.

Advantages of Freeze Dried private label pet treat

Continuing the purity of raw materials, strictly implementing human edible standards.

Made of pure meat, good palatability, no additives.

Keep the fresh and characteristic products of the ingredients easy to digest and absorb.

High nutritional protein content up to 80%.

Pasteurization & Radiation Sterilization Product Safety.

Freeze-drying process for long-lasting quality without preservatives.

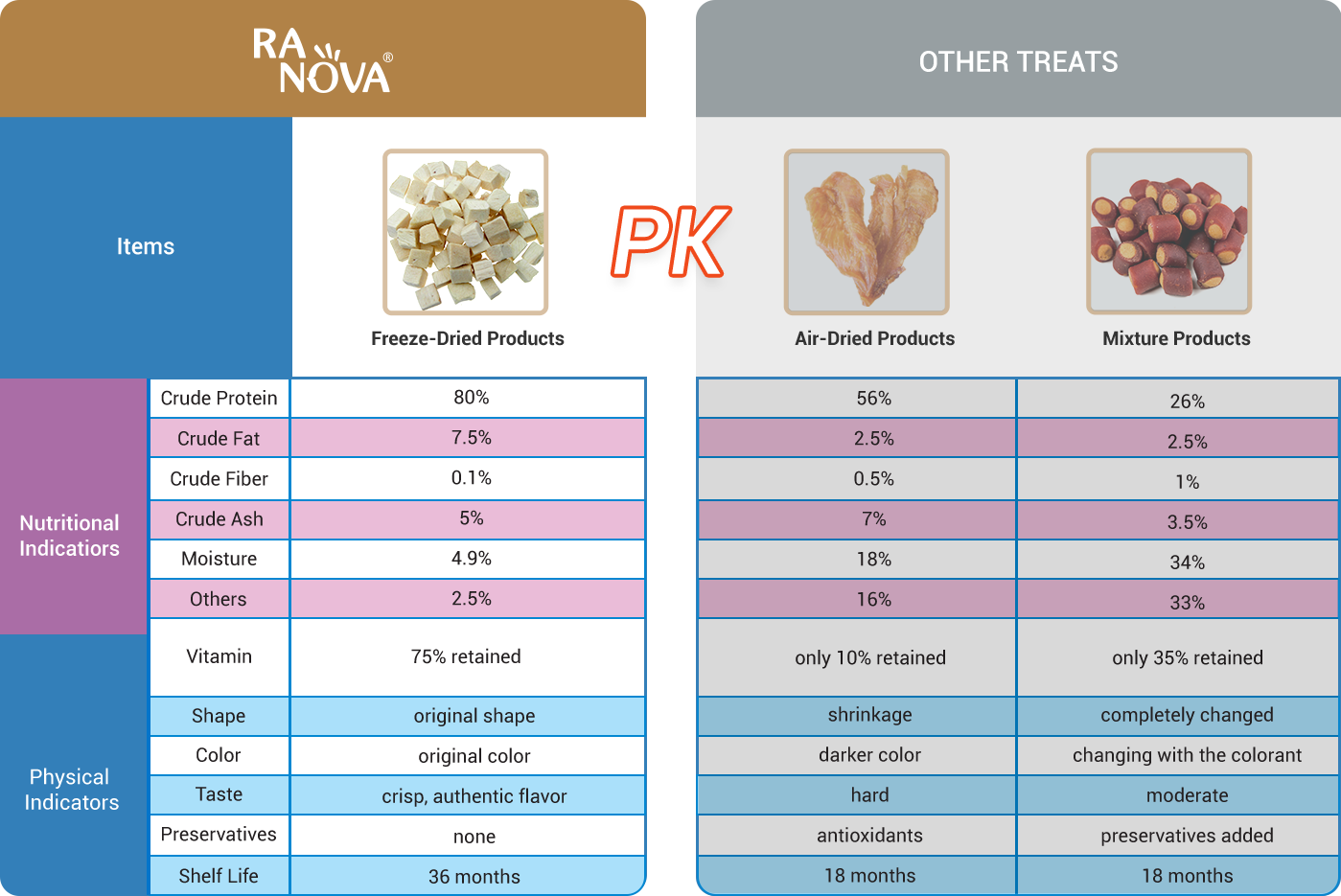

Advantages of Freeze-Dried Product Comparing with Other Treats

Quality Assurance of Freeze-Dried Product Comparing with Other Treats

Raw Material Standard

All raw materials are of high quality and conform to standards for human edibility.

Raw Material Standard

The high-tech freeze-drying equipment, with its six internal systems, ensures that the organizational structure and nutrients of raw materials are not destroyed.

Raw Material Standard

The production workshop is designed in accordance with the health standards for food factories. Its equipment, containers, tools, and workers' uniforms are regularly disinfected. The employees must take regular physical examinations, so as to prevent and control bacterial diseases and guarantee the safety of products.

Freeze-drying Process of Freeze-Dried Product Comparing with Other Treats1st Step

1st Step

Fresh pure meat is chosen and cut into pieces without applying any other ingredients, while the fat, skin, and bones are removed.

2nd Step

Freeze the meat at -32℃ to retain its nutrition.

3rd Step

Vacuum freeze-drying for 18 to 36 hours to sublimate its water, raising temperature to 72℃ for sterilization, completing the entire freeze-drying process.

4th Step

Select qualified semi-finished products and remove the imperfect ones.

5th Step

Package finished products, irradiate them for sterilization.

Localisation : No.2 Road, North Area, Jinghai Economic Development Area, Tianjin 301600, China, 301600 tianjin,

Personne à contacter : Liu Zhe Zhe, +18 5 02 20 20 68