COSMOPlat is wholly owned by Haier Group which is a world-leading provider of solutions to better life. As the world's first and only IoT ecosystem brand, Haier COSMOPlat has been included on the list of BrandZ™ Top 100 Most Valuable Global Brands for two consecutive years. Haier offers mold and molding services for over 1 billion families in 160 countries or regions around the world.

Home

Aerospace refers to various aircraft that move in accordance with the laws of celestial mechanics in the outer space of the earth's atmosphere. The products we provide include but are not limited to Helicopters, Passenger, Planes, Rockets and other space tools. We are committed enough to meet all your needs.

Aerospace injection molding is strictly designed with the feature of high-precision. Thus 3D printing in aviation and 3D printing in aerospace are applied widely for it can simplify the mass production of aerospace parts and components.

Aerospace Injection Molding Products by COSMOPlat

Aerospace Injection Molding Overview

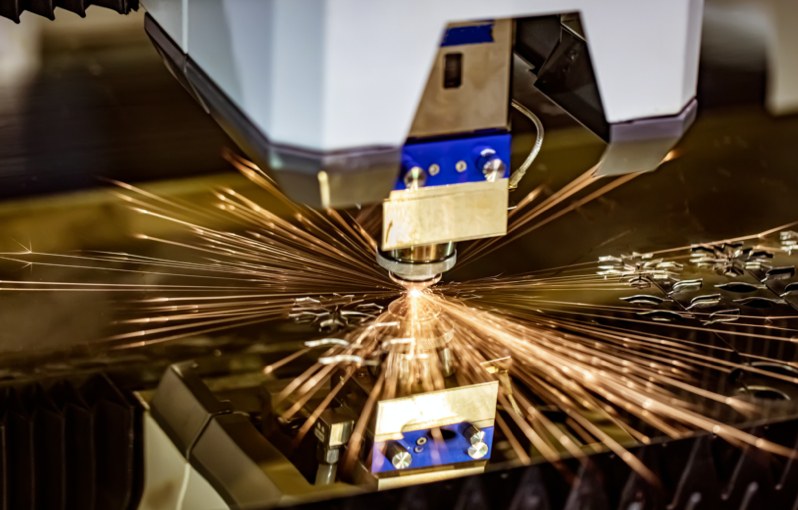

Injection molding is a part of manufacturing parts that are used in the aerospace engineering sector. Turbine housings, turbine blades and pin diagrams used to mold carbon or glass fiber into thin sheet applications are aerospace molded plastic components. Aerospace molded plastic components should be manufactured with the highest level of precision. Parts are produced to perfect specifications and precise measurements. Only in this way of strict requirement can the products be able to withstand the demanding conditions required for aerospace applications.COSMOPlat owns the mature process and technology of aerospace injection molding. We aim to provide not only great products but also reliable custom service.

Materials Used in Aerospace Molded Plastic Components

Here in COSMOPlat, we offer our customers with high quality aerospace molded plastic components. Materials, therefore, are of great importance during the whole process. We use various types of materials, which enables us to have more choice in satisfying your needs of aerospace molded plastic components production. These materials include but not limited to thermoplastic resins, PEEK, ABS, polypropylene, acetal, polyethylene, nylon, polyetherimide.

Advantages of Injection Molding in Aerospace Industry

Aerospace injection molding is featured with many advantages, and that's why it is preferred over other methods to manufacture most of the components or parts that are used in the aerospace industry. These benefits include: · Unparallel repeatability. With this advantage, components or parts with similar or the same features can be produced on a large scale.· Cost-effectiveness. Due to the outstanding repeatability, the manufacturers are able to produce a large quantities of components in a lower cost.· Design flexibility. With injection molding, the designers are allowed to conduct parts integration after considering the condition of the interior parts of an aircraft.

Localisation : Innovation in A seat, No.1 Haier Road, Qingdao, Shandong Province, 266101 Qingdao,

Personne à contacter : Yokini Wang, 021 67696068