|

|

|

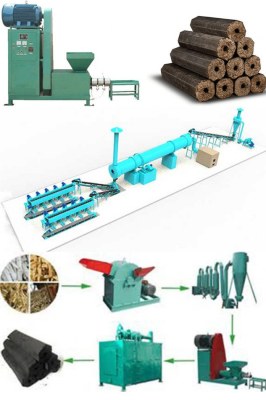

Biens d'équipement

Biomass Charcoal Briquette Machine Guideline

|

|

Cette page concerne les importateurs et exportateurs de Biomass Charcoal Briquette Machine Guideline Rechercher dans la catégorie : Biens d'équipement Rechercher dans la catégorie : briquette, guideline, biomass, charcoal, machine |

Mardi 17 décembre 2024

Quantité : 80000 Ream - Prix : $0.79/Ream for 8000

CARACTÉRISTIQUES - Dimensions de la feuille: 210mm x 297mm / 297mm x 420mm normes International Paper Taille (ISO) A4 / A3 - Qualité: importé 100% pâte de bois vierge - Blancheur: 102-104%, blanc naturel - Classement: A - Epaisseur: 106cm - Capacité: copie à grande vitesse de 100 ppm...

NATH LAOH LTD

- 50100 - Chiang Mai

- +66 9 95 35 59 56

Mercredi 30 septembre 2015

Quantité : 50000 - Prix : depend de quantite

De grande qualité, agréable au toucher, légère, douce, Ultra-absorbante et sèche vite : Votre Fouta vous suivra partout, dans votre salle de bain, à la piscine, à la plage, sur le transat, le bateau ou en paréo, entourant les bébés, les enfants à la sortie du bain. Dans vos bagages...

artisanat Tunisien

- med.SGHAIER

- 5099 - Tunisia,Monastire

- +21 6 26 10 49 12

- 26104912

Mardi 17 décembre 2024

Quantité : 80000 Ream - Prix : $0.79/Ream for 8000

CARACTÉRISTIQUES Copie papier Paperone A4 80GSM Caractéristiques de papier A4 papier Une copie 80g: Substance G / M2 + 80 - 2.5 - Substance Variation Cd - Epaisseur Différence Cd% Egal à / En dessous de 10 - Luminosité% 100-102 - Opacité% Egal à / Inférieur à 90 - Breaking...

NATH LAOH LTD

- 50100 - Chiang Mai

- +66 9 95 35 59 56