Hot-dip galvanizing has the advantages of uniform coating, strong adhesion and long service life.

The dense zinc-iron alloy layer of the hot-dip galvanized steel pipe is integrated with the pure zinc layer and the steel tube base, which has strong corrosion resistance.

As long as the forming angle is changed, hot dip galvanized steel tubes of various calibers can be produced from strip steel of the same width.

Continuous bending and forming, the fixed length of the spiral tube is not limited, and the length can be customized.

The spiral welds are evenly distributed on the circumference of the spiral pipe, so the spiral pipe has high dimensional accuracy and strong strength.

It is suitable for the production of small batches and multiple varieties of spiral tubes. The welding seam of hot dip galvanized pipe is longer than the welding seam of straight seam pipe of the same specification. With the same wall thickness, the hot dip galvanized pipe bears the greatest pressure.

HDG pipe, which is also called Hot Dip Galvanized Pipe or Galvanised Metal Pipe.

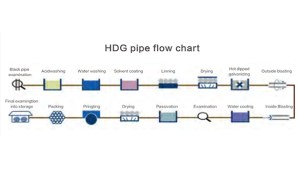

1. Hot-dip Galvanized Steel Pipe Process Flow Chart

Welded pipe inspection - pickling - washing - coating solvent - aligning - drying - hot galvanizing - external blowing - internal blowing - water cooling - intermediate inspection - passivation - drying - typing - packaging - final inspection

2. Steel-plastic Composite Pipe Process Flow Chart

Raw material inspection - plastic extrusion - sampling test - cut to length - inner wall purge - sandblasting - galvanized pipe inspection - traction through pipe - heating composite - passivation - inspection - packaging

3. Application of Hot Dip Galvanized Steel Pipe

Like erw steel , industrial hot-dip galvanized steel are widely used in construction, machinery, coal, chemical, electric power, railway vehicles, automotive industry, roads, bridges, containers, sports facilities, agricultural machinery, petroleum machinery, prospecting machinery manufacturing industry.

Hot-dip galvanizing (HDG) is the reaction of molten metal with an iron matrix to produce an alloy layer, thereby combining the substrate and the plating. Hot-dip galvanizing is to pickle the steel pipe first, in order to remove the iron oxide on the surface of the steel pipe, after pickling, it is washed by ammonium chloride or zinc chloride aqueous solution or a mixed aqueous solution of ammonium chloride and zinc chloride, and then fed. Hot dip plating tank. Hot-dip galvanizing steel pipe has the advantages of uniform plating, strong adhesion and long service life.

Galvanizing is a technology of rust protection. The steel and zinc are will interact and become Zn-Fe alloy on the pipe surface. The layer of alloy can provide protection from outside oxidation and extend the pipe use life. The service life of a galvanized steel pipe can be 20-30 years in the outdoor environment.

Welded galvanized steel pipe with hot-dip or electric galvanized layer on the surface. Galvanized steel can increase the corrosion resistance of the steel and prolong the service life. Galvanized pipe USES is very wide, in addition to a generally low-pressure fluid such as water, gas, oil line pipe, also used as the oil industry, especially the ocean oil field oil well pipe, oil pipe, chemical coking equipment of oil heater, the condensing, exchange of coal distillation wash oil cooler for the tube, and trestle pile, mining tunnel supporting frame tube, etc.

Hot-dip galvanized pipe manufacturers always provide customers with products according to their needs, and Tianchuang can be the best of them. Contact us and get the price for galvanized steel pipe.

Hebei Tianchuang Pipe Co., Ltd. is a professional hot dip galvanized pipe manufacturers and china steel pipe factory. We provide HDG Pipe, ERW Pipe and so on. Want to know about hot dip galvanized steel pipe price? Please contact us.

Localisation : Yongnian Industrial Park, Handan City, Hebei Province, China., 057150 Yongnian Industrial Park,

Personne à contacter : Li Simon, 0310 6668080