GM-TECH,a injection molding companies in china, has been manufacturing tools for injection molding of plastics for various industries for more than 10 years. We are also experienced in automotive, electrical and home appliance industries but also manufacture moulds for other industries requiring plastic injection moulds. We are able to offer you complete services in this area, from design of the moulds, over their high-quality manufacturing in own tool shop.

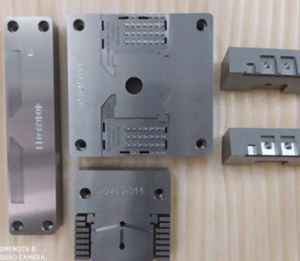

Mould Components / precision mold components are also a part of the mould.GM-TECH not only produces precision moulds but also provides customers with high-precision, low-cost mould parts. For example mould cores, inserts, sliders, lifter, wear plates, ejector pins, etc. Usually, processing accuracy can be controlled within + /-0.015mm. Delivery time is 2-3 weeks, DHL or FedEx will take about 3 days for shipping.

All the steel and tolerances of the parts are processed according to the drawings of the customers. In order to ensure the quality of parts processing, we will provide customers with dimensional measurement report, hardness measurement report, material proof.

We also use new technology to do DLC surface treatment to guarantee the life of the parts.

Mould Component Features

All the steel and tolerances of the parts are processed according to the drawings of the customers. In order to ensure the quality of parts processing, we will provide customers with dimensional measurement report, hardness measurement report, material proof.

We also use new technology to do DLC surface treatment to guarantee the life of the parts.

Plastic injection mold components / Plastic mold components / Injection mold components are also a part of the mould.GM-TECH not only produces precision moulds but also provides customers with high-precision, low-cost mould parts. For example: mould cores, inserts, sliders, lifter, wear plates, ejector pins, etc. Usually, processing accuracy can be controlled within + /-0.015mm. Delivery time is 2-3 weeks, DHL or FedEx will take about 3 days for shipping.

All the steel and tolerances of the parts are processed according to the drawings of the customers. In order to ensure the quality of parts processing, we will provide customers with dimensional measurement report, hardness measurement report, material proof.

We also use new technology to do DLC surface treatment to guarantee the life of the parts.

We also provide metal insert molding and plastic parts injection molding.

Localisation : Shengan Building A, Hengzeng Road Chang'an Town, Dongguan, Guangdong, China, 52388 Dongguan,

Personne à contacter : Kevin Shaw, 0086 0769 8535 7333