Although we use sugar on a daily basis, most people do not know how the processes of extracting liquid juice from sugarcane. To extract juice, the sugar cane is literally crushed to remove the juice. As a result, a fibrous byproduct called bagasse is left behind. From every ten tonnes of sugarcane, 3 tonnes of bagasse is produced. It is usually changed into pellet form for ease of use. Interestingly even though bagasse is merely a by-product of sugar production, it has many advantageous qualities.

Creation Of Sugarcane Bagasse Pellets

The moisture content of bagasse is nearly 40 to 50 percent. This property makes it an inefficient fuel source. For this reason, further processing is required. When it has to be used as a source of electricity, it needs to be stored while moist to avoid over-drying. For use in paper production, it is stored in wet conditions to aid in excess sugar removal. Before the storage stage, bagasse pellets need to be created from the fibrous raw source.

Bagasse Pellets Applications

As a Fuel Source

Because bagasse pellets are created from sugar production, they are mainly used as fuel sources for sugar factories. When large quantities of bagasse are burned, an excess of energy in the form of heat is released. This can often power an entire sugar mill. Since such a large amount of energy is created through combustion, excess energy can be sold onto the consumer electrical grid to create electricity. Some sugar mill owners sell their excess bagasse pellets to other factories with boilers or export them to foreign countries. Recently many East Asian countries such as China have started imported large quantities of bagasse pellets. An average size power plant usually consumes over 10,000 tonnes of bagasse pellets every month.

As Animal Feed

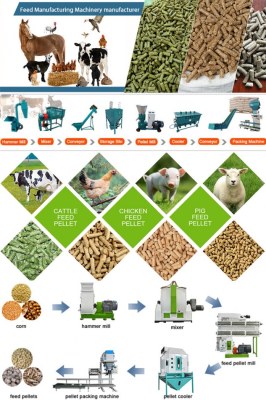

Another way to use bagasse pellets is to feed livestock. To use bagasse as feed, it must be processed further by fermenting. In this step of the process, enzymes and molasses are added to the pellets. Many countries market their pellets as 'fiber rich'. Fusmar animal feed pellet machine can make bagasse pellets.

As Pulp and Paper

In countries such as India, China, Colombia, Iran, Thailand and Argentina, bagasse is used in lieu of wood to create paper and pulp. Bagasse has good qualities for creating paper for mass production and distribution. It is also used to create thicker material boxes and boards as a substitute for plywood. Many companies even use it to build furniture.

How To Build A Sugarcane Bagasse Pellet Plant

If you want to create your own sugarcane bagasse feed pellet production plant, the first thing you need to do is decide if you want to process sugar cane and bagasse pellets or only bagasse pellets. Processing only sugarcane bagasse pellets is a relatively easier business. You can contact local sugar mills to see if you can purchase their raw bagasse, pre-processing.

The machine you will need to buy is a feed pellet mill machine. You cannot spare any expense while purchasing a pellet machine. In the first step the material is simply loaded into the machine. Most machines come with mechanisms to avoid any spillage or loss of material. The second step involves the formation of pellet shapes with a ring die. The machines are created to withstand vibration to ensure high quality pellet formation.

Localisation : No.45 Agricultural Road, Jinshui District, Zhengzhou, Henan China, 450003 Zhengzhou,

Personne à contacter : Yan Amy, +8615838279423