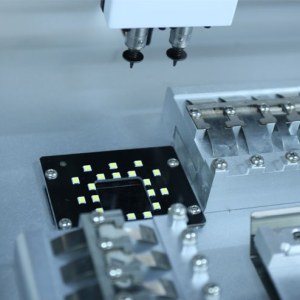

The pick and place machine is the equipment used to achieve high-speed and high-precision placement of components in the production line, it is configured after the dispenser screen printing machine. The surface mount components are accurately mounted by moving the mounting head. The PCB pad is the most critical, complex, and important equipment in the entire SMT line. The use of the CNC pick and place machine for PCB assembly line requires a certain amount of professional basic knowledge in this field including but not limited to various resistance-capacitance chip components, IC, PCB design and processing, steel mesh, solder paste brushing, reflow soldering, connection table, and inspection, etc related information.

Types of Pick and Place Machine For Sale

Pick and Place Machine TronStol A1

SMT line machine is an equipment used to achieve high-speed and high-precision placement of components in the production line, it is configured after the dispenser or screenprinting machine. The surface mount components are accurately mounted by moving the mounting head.

Pick and Place Machine TronStol 3V Advanced

It features dual head, 46 feeder slots, vision system, and flexible positioning system, which is suitable for prototyping, small batch production with stable performance and affordable price.

Pick and Place Machine TronStol 3V Standard

It features dual head, 25 feeder slots ,vision system, and flexible positioning system, which is suitable for prototyping, small batch production with stable performance and affordable price.

FAQs Of Pick And Place Machine

How Does The Pick And Place Equipment Work?

A.

The pick and place (PNP) machine is a robotic assembly device that uses a vacuum to lift a component off a piece of tape, rotates it to the right orientation, then places it on a circuit board, according to which it is also called the circuit board assembly machine. It takes a few hours to set up a machine to build the assembly, but once everything is running, it works very fast.

Where The Pick And Place Equipment Is Used?

A.

It loads different working files to mount the corresponding PCB. If you want to know more about the price of a PCB pick and place machine/ PCB soldering machine/ PCB component placement machine/ PCB SMT assembly machine, please contact us!

What Is The Difference Between SMT And SMD?

A.

The difference between an SMD assembly machine and an SMT assembly machine is that SMD (surface mount device) refers to electronic components mounted on PCB. In contrast, SMT (surface mount technology) involves a method for placing electronic components on a printed circuit board. Our company provides various pick and place machines, for example, small SMT pick and place machine/ placement machine, SMT chip mounter/ mounting machine, SMT soldering machine, and mini SMD component mounting machine/ surface mount device, SMD pick and place machine/ placement machine, SMD surface mount device/ mounting machine, SMD soldering machine.

Hang Zhou Tronstol technology Co., Ltd. is one of smt pick and place machine manufacturers. We provide Prototype SMT Line, Small Production SMD Line, low cost pick and place machine, pcb smt machine, pick and place machine open source, pick and place packaging machine, pick and place pcb machine, cheap smt pick and place and so on. Want to know more? Please contact us.

Localisation : 4th Floor, Building 5, No. 2, Huayi Road, Yuhang Street, Yuhang District, Hangzhou, China, 311121 Huayi Road,

Personne à contacter : STOL TRON, +19 8 16 87 95 53