|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Divers

Jaw Crusher

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Model |

Feed opening(mm) |

Max.feeding size(mm) |

Adjusting range of discharge opening(mm) |

Processing capacity(t/h) |

Rotation speed of eccentric shaft(r/min) |

Motor power(kw) |

Total weight(t) |

Dimensions(L×W×H)(mm) |

|

PE-150×250 |

150×250 |

125 |

10-40 |

1-3 |

250 |

4P 5.5 |

0.8 |

720×660×850 |

|

PE-200×300 |

200×300 |

180 |

15-50 |

2-6 |

260 |

4P 7.5 |

1.2 |

910×750×990 |

|

PE-200×350 |

200×350 |

180 |

18-70 |

3-10 |

260 |

4P 11 |

1.5 |

1000×870×990 |

|

PE-250×400 |

250×400 |

210 |

20-60 |

5-20 |

300 |

6P 15 |

2.8 |

1300×1090×1270 |

|

PE-400×600 |

400×600 |

340 |

40-100 |

16-60 |

275 |

6P 30 |

7 |

1730×1730×1630 |

|

PE-500×750 |

500×750 |

425 |

50-100 |

40-110 |

275 |

6P 55 |

12 |

1980×2080×1870 |

|

PE-600×750 |

600×750 |

500 |

150-200 |

80-240 |

275 |

6P 55 |

15.8 |

2070×2000×1920 |

|

PE-600×900 |

600×900 |

500 |

65-160 |

50-160 |

250 |

6P 55 |

17 |

2190×2206×2300 |

|

PE-750×1060 |

750×1060 |

630 |

80-140 |

110-320 |

250 |

8P 110 |

29 |

2660×2430×2800 |

|

PE-800×1060 |

800×1060 |

640 |

130-190 |

130-330 |

250 |

8P 110 |

29.8 |

2710×2430×2800 |

|

PE-830×1060 |

830×1060 |

650 |

160-220 |

150-336 |

250 |

8P 110 |

30.7 |

2740×2430×2800 |

|

PE-870×1060 |

870×1060 |

660 |

200-260 |

190-336 |

250 |

8P 110 |

31.5 |

2810×2430×2800 |

|

PE-900×1060 |

900×1060 |

685 |

230-290 |

230-390 |

250 |

8P 110 |

33 |

2870×2420×2940 |

|

PE-900×1200 |

900×1200 |

750 |

95-165 |

220-450 |

200 |

8P 110 |

52 |

3380×2870×3330 |

|

PE-1000×1200 |

1000×1200 |

850 |

195-265 |

315-500 |

200 |

8P 110 |

55 |

3480×2876×3330 |

|

PE-1200×1500 |

1200×1500 |

1020 |

150-350 |

400-800 |

180 |

6P 160-220 |

100.9 |

4200×3300×3500 |

|

PE-1500×1800 |

1500×1800 |

1200 |

220-350 |

500-1000 |

180 |

8P 280-355 |

139 |

5160×3660×4248 |

|

PE-1600×2100 |

1600×2100 |

1500 |

300-400 |

1300-2200 |

160 |

8P 350-380 |

150.6 |

6210×4013×4716 |

|

PEX-150×750 |

150×750 |

120 |

18-48 |

8-25 |

320 |

4P 15 |

3.8 |

1200×1530×1060 |

|

PEX-250×750 |

250×750 |

210 |

25-60 |

13-35 |

330 |

6P 22 |

5.5 |

1380×1750×1540 |

|

PEX-250×1000 |

250×1000 |

210 |

25-60 |

16-52 |

330 |

6P 30 |

7 |

1560×1950×1390 |

|

PEX-250×1200 |

250×1200 |

210 |

25-60 |

20-61 |

330 |

6P 37 |

9.7 |

2140×1660×1500 |

|

PEX-300×1300 |

300×1300 |

250 |

20-90 |

16-105 |

300 |

6P 55 |

15.6 |

2720×1950×1600 |

|

Category |

UNIT |

Jaw Crushers |

Fine Type Crushers |

|||

|

150x250 |

250x400 |

400x600 |

150x750 |

250x750 |

||

|

Iniet size |

mm |

150x250 |

250x400 |

400x600 |

150x750 |

250x750 |

|

Outlet width |

mm |

15-45 |

20-100 |

30-100 |

18-60 |

25-100 |

|

Rorary speed of crusher eccentric shaft |

r/min |

340 |

320 |

267 |

320 |

303 |

|

Electric motor,s model |

|

Y132S-4 |

Y160L-4 |

Y225M-6 |

Y180L-6 |

Y225M-6 |

|

Electric motor,s power |

kw |

5.5 |

15 |

30 |

15 |

30 |

|

Electric motor,s speed |

r/min |

1440 |

1460 |

980 |

|

|

|

Contour dimension of crusher |

LxBxH |

800x745x820 |

1230x1051x1091 |

1560x1660x1535 |

1220x1442x928 |

1450x1636x1288 |

|

Weight |

kg |

850 |

2300 |

5800 |

3000 |

4800 |

|

Productivity |

m3/h |

1.5-4.5 |

5-20 |

10-34 |

5-15 |

10-30

|

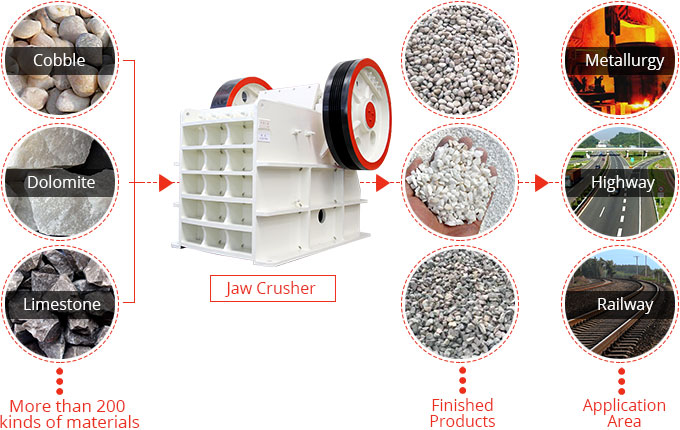

Jaw crusher, in short, we call it as JC. It is an early breakup equipment, because it has simple structure. It is strong, reliable, easy to maintain and repair. Besides, it costs less money of production and construction. Therefore, until now, it is still widely used in metallurgical, chemical, building materials, power, transportation and other industrial sectors. It is mainly used for crushing all kinds of ores or coarse, medium and fine stones with compression strength of 147- 245 MPa. In order to meet the needs of crushing high strength and high hardness in metallurgical, mining, construction and other industries, GUIKUANG machinery has been investing a lot of manpower, material and financial resources to develop a new type jaw crusher with high efficiency and energy saving. Therefore, more and more new jaw crusher will be introduced. It is welcome to continue to pay attention to our factory.The jaw crusher is mainly used for medium size crushing of the various ore and large pieces of materials. It is widely used in mines, smelting, building materials, highway, railway, water conservancy and chemical industries.

The Operational Principles of Jaw Crusher

The operate mode of jaw crusher is curved extrusion type. The operational principle is that the motor drives the belt and the pulley to move the jaw up and down through the eccentric shaft. When the moving jaw rises, the angle between the elbow plate and the moving jaw increases, thus it will push the moving jaw plate be close to the fixed jaw plate. At the same time, the material is crushed or chopped, so the purpose is achieved; when the moving jaw descends, the angle between the elbow plate and the moving jaw decreases. Under the action of the pull rod and the spring, the moving jaw plate leaves the fixed jaw plate. At the same time, the broken material has been discharged from the lower mouth of the crushing chamber. With the continuous rotation of the motor, the moving jaw is crushing and discharging the materials for periodic movement to achieve mass production.

The Performance and Characteristics of Jaw Crusher

1. Advanced manufacturing techniqueGUIKUANG jaw crusher is made of advanced materials with advanced manufacturing technique; it adopts finite element analysis technology. The equipment has higher working strength and helps to improve the production efficiency.

2. The bearing is durableThe bearing seat of the jaw crusher adopts the integral cast steel structure, which can guarantee the complete match with the broken frame, and greatly enhance the radial strength of the bearing seat. Compared with the crusher which has the same specifications, it has larger and more durable bearing. According to its higher bearing capacity and the effective sealed bearing, it will prolong the usage time greatly.

3. The quality of the moving jaw is reliableThe GUIKUANG jaw crusher has more advanced moving jaw assembly, which makes it more durable. The moving jaw assembly is made of high quality steel castings, and is driven by two large cast steel flywheels. In addition, the heavy eccentricity shaft also adopt the way of processing semi-finished product. All of these make the jaw crusher equipped with extraordinary reliability.

4. Convenient adjustment of dischargingThe crushing chamber of the jaw crusher adopts the symmetrical "V" shape structure, which makes the width of the actual feeding port consistent with that of the nominal intake port. So it is more quick and convenient to the adjust the discharging gate. The jaw crusher is also equipped with a wedge discharging gate adjustment device, which is simpler, safer and faster than the old gasket adjustment type.

The Price of Jaw Crusher

When customers buy jaw crushers, they need to paying attention to the performance and quality of the jaw crusher itself. Besides, the price of the jaw crusher is undoubtedly the customer's concern. Especially for the jaw crusher, which is produced by many different factories. So people need to be careful to buy it. As we know, the price of a jaw crusher is not cheap.The price of jaw crusher is influenced by many factors, such as factory, specification, quality, area, market demand and so on. Different jaw crusher manufacturers will produce products with different performance and quality. Therefore, when customers buy jaw crusher, they must purchase in the true manufacturers.

Jaw Crusher for Sale from GUIKUANG - an expert manufacturer in crushing and mining equipment!

Personne à contacter : Zeng Ralap , 0773 6812095

Bonne affaire : acheter au vendeur

Nous vous invitons à lire nos conditions générales d'utilisations. Vous pouvez aussi vous rendre sur nos FAQ et consulter notre page d'informations sur les risques liés à la contrefaçon.

|

Cette page concerne les importateurs et exportateurs de Jaw Crusher Rechercher dans la catégorie : Divers Rechercher dans la catégorie : crusher |

Dimanche 10 août 2014

Quantité : 25 - Prix : USD 3900-88888

Quick Details Condition: New Type: Rotary Drying Equipment,drying machine Place of Origin: Henan China (Mainland) Brand Name: YongHua Model Number: GZ Series Voltage: 380v/50hz Power(W): 22kw Dimension(L*W*H): According to customer's requirement Weight: 8t Certification...

Henan Zhengzhou Yonghua Machinery

- olina1

- 450000 - zhengzhou CITY

- +13 6 07 69 93 63

Jeudi 10 mars 2016

Introduction: LSG-3000 Moving Detector Goniophotometer completely meets LM-79 Clause 9.3.1 requirement. The LSG-3000 is an automatic light distribution intensity 3D curve testing system for measuring light. The measuring distance is from 5m to 30m. It can measure all types of lighting sources...

Lisun Electronics (Shanghai) Co., Ltd.

- 201803 - Shanghai

- +86 021 51083341

- +86 18917996096

Mardi 30 août 2016

Prix : 10,00 €

HPC-GD-27A GSM900 and DCS1800mhz Dual band signal repeatersProduct introductionMobile signal booster is designed to enhance the indoor mobile phone signal. The main reason leads to the weak indoor signal is the rebar inside of the concrete walls. Because the rebar will absorb and...

Shenzhen Sai Tong Tian Electronic Technology Co.,LTD

- 518000 - Shenzhen

- 86 0755 33090206

- 0755 15817483863